Turboset condenser

A steam turbine unit and condenser technology, which is applied to steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc., can solve the problem of affecting the space layout of the steam turbine unit, high cost of operation of the steam turbine unit, site and equipment investment There are many problems, and the effect of heat exchange cooling and cooling is obvious, the effect of cooling and cooling is improved, and the stability is ensured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

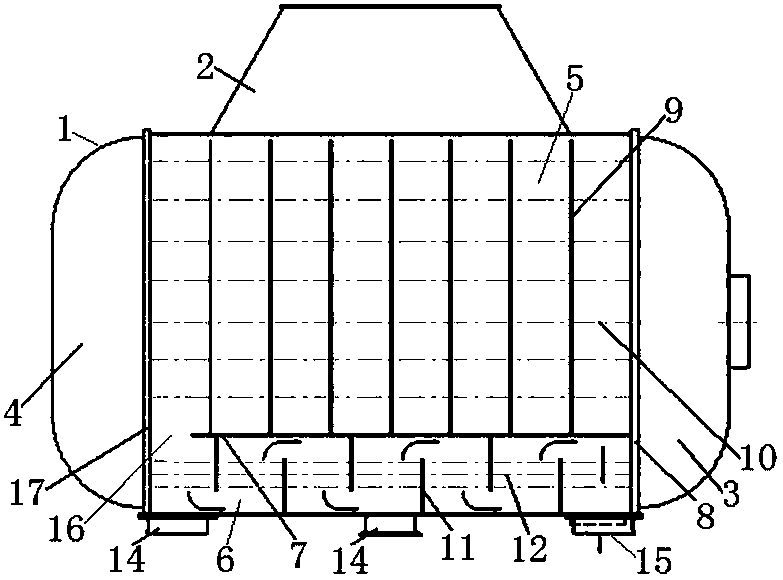

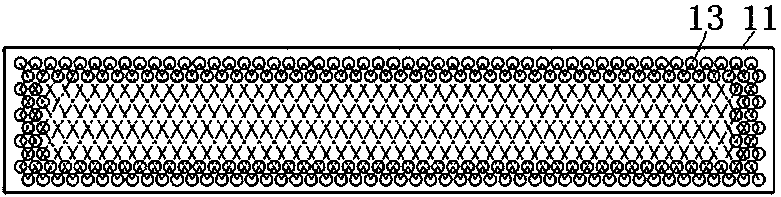

[0023] see figure 2 with image 3 As shown, the present invention comprises shell 1, and the top of this shell 1 has the throat 2 that connects steam turbine exhaust pipe, and the bottom of shell 1 has a plurality of supports 14, and the inside of shell 1 is made of end pipes on both sides. Plate—that is, the front tube plate 8 and the rear tube plate 17 are divided into a front water chamber 3, a heat exchange chamber and a rear water chamber 4, and the front water chamber 3 has a cooling water inlet and a cooling water outlet.

[0024] The heat exchange chamber is divided into an upper condensation zone 5 and a lower cooling zone 6 by partition partitions 7 in the up and down direction. The partition partition 7 is located at the lower part of the heat exchange chamber, the front end of the partition partition 7 is in sealing contact with the front tube plate 8 at the front end of the heat exchange chamber, and the rear end of the partition partition 7 is in contact with t...

Embodiment 2

[0030] see Figure 4 with Figure 5 As shown, the present invention comprises shell 1, and the top of this shell 1 has the throat 2 that connects steam turbine exhaust pipe, and the bottom of shell 1 has a plurality of supports 14, and the inside of shell 1 is made of end pipes on both sides. Plate—that is, the front tube plate 8 and the rear tube plate 17 are divided into a front water chamber 3, a heat exchange chamber and a rear water chamber 4, and the front water chamber 3 has a cooling water inlet and a cooling water outlet.

[0031]The heat exchange chamber is divided into an upper condensation zone 5 and a lower cooling zone 6 by partition partitions 7 in the up and down direction. The partition partition 7 is located at the lower part of the heat exchange chamber, the front end of the partition partition 7 is in sealing contact with the front tube plate 8 at the front end of the heat exchange chamber, and the rear end of the partition partition 7 is in contact with t...

Embodiment 3

[0037] The invention comprises a shell, the top of which has a throat connected to the exhaust pipe of the steam turbine, the bottom of the shell has a plurality of supports, and the inside of the shell is composed of end tube plates on both sides - namely the front end tube plate and the rear end tube plate. The tube sheet is divided into a front water chamber, a heat exchange chamber and a rear water chamber, and the front water chamber has a cooling water inlet and a cooling water outlet.

[0038] The heat exchange chamber is divided into an upper condensation zone and a lower cooling zone by partition partitions in the up and down direction. The partition partition is located at the lower part of the heat exchange chamber, the front end of the partition partition is in sealing contact with the front tube sheet at the front end of the heat exchange chamber, and the rear end of the partition partition is in contact with the rear tube sheet at the rear end of the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com