A heat treatment device for the production of machine tool rotary shafts

A heat treatment device and rotary shaft technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of inability to collect slag, waste of resources, etc., achieve good cooling, realize recycling, and improve the effect of quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

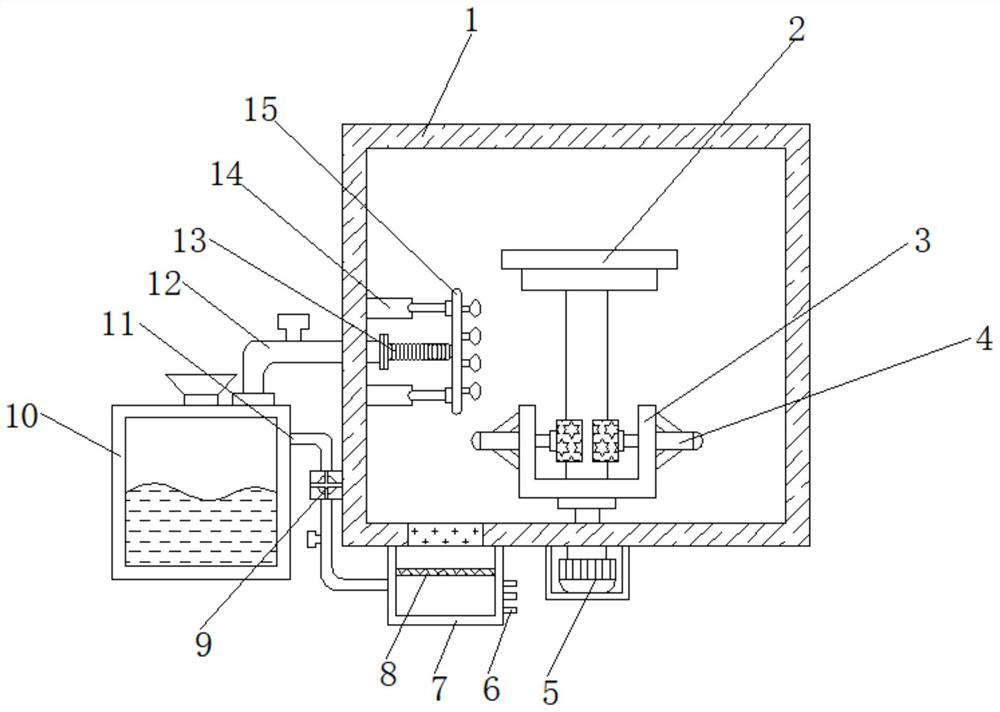

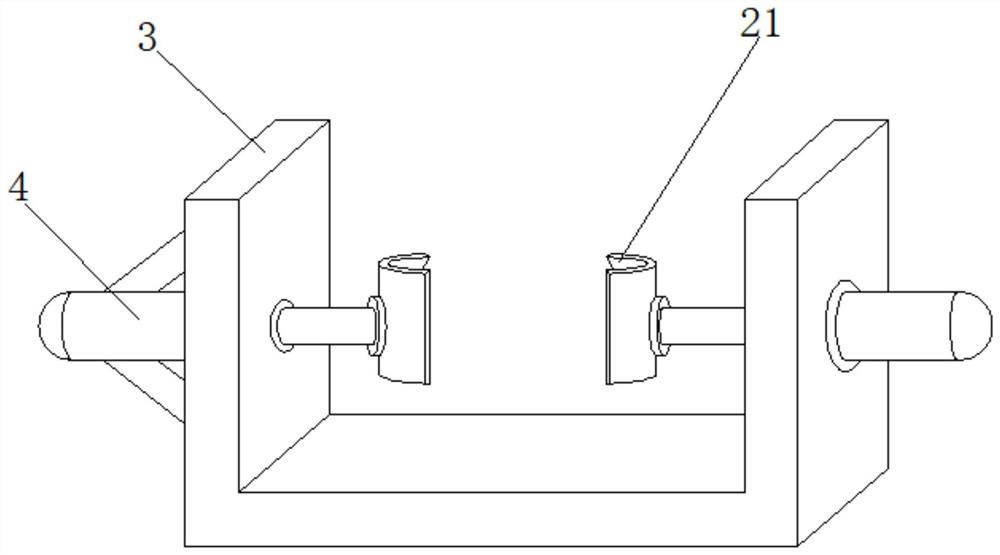

[0026] refer to Figure 1-2 , a heat treatment device for the production of machine tool rotary shafts, comprising a quenching box 1 and a liquid storage box 10, the bottom outer wall of the quenching box 1 is connected to an organic casing by bolts, and a motor 5 is connected to the bottom inner wall of the casing by bolts, and the output of the motor 5 is The outer wall of one end of the shaft is connected with a fixed frame 3 by bolts, and the outer walls of both sides of the fixed frame 3 are connected with a first electric push rod 4 by bolts, and the outer wall of one end of the first electric push rod 4 is connected with a clamping ring 21 by bolts, and The inner wall of one side of the clamping ring 21 clamps the rotary shaft body 2, the top outer wall of the liquid storage tank 10 is plugged with a liquid outlet pipe 12, and the inner wall of one end of the liquid outlet pipe 12 is inserted with a bellows 13, and the bellows 13 A nozzle 15 is plugged into one end, and...

Embodiment 2

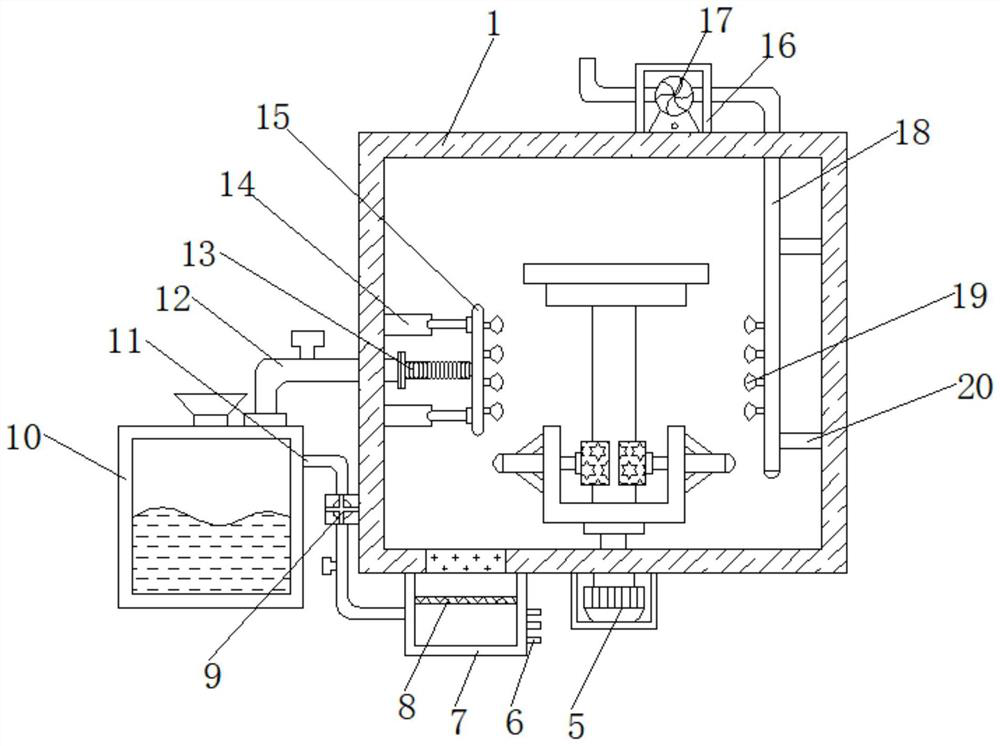

[0030] refer to image 3 , a heat treatment device for the production of machine tool rotary shafts. Compared with Embodiment 1, the top outer wall of the quenching box 1 is connected with a protective shell 16 by bolts, and the bottom inner wall of the protective shell 16 is connected with a blower 17 by bolts. One side outer wall of 17 is plugged with air outlet pipe 18, and one side outer wall of air outlet pipe 18 is plugged with equidistantly distributed air outlet buckets 19, and one side outer wall of air outlet pipe 18 is welded with reinforcing bar 20, and reinforcing bar One end of 20 is welded on one side inner wall of quenching box 1.

[0031]Working principle: When in use, place it on the bottom of the fixed frame 3 before the device quenches the rotary shaft body 2, then start the first electric push rod 4, and the first electric push rod 4 drives the clamping ring 21 to return The rotating shaft body 2 is fixed to ensure the stability of the rotating shaft body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com