A powder spreading device applied to laser additive manufacturing

A powder spreading device and laser additive technology, applied in the field of additive manufacturing, can solve the problems of powder raw material waste, powder scattering, etc., and achieve the effect of easy implementation, simple mechanical structure, and improved raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below by means of an embodiment and its drawings, but this embodiment and the drawings are only illustrative, and the scope of protection of the present invention is not limited thereto.

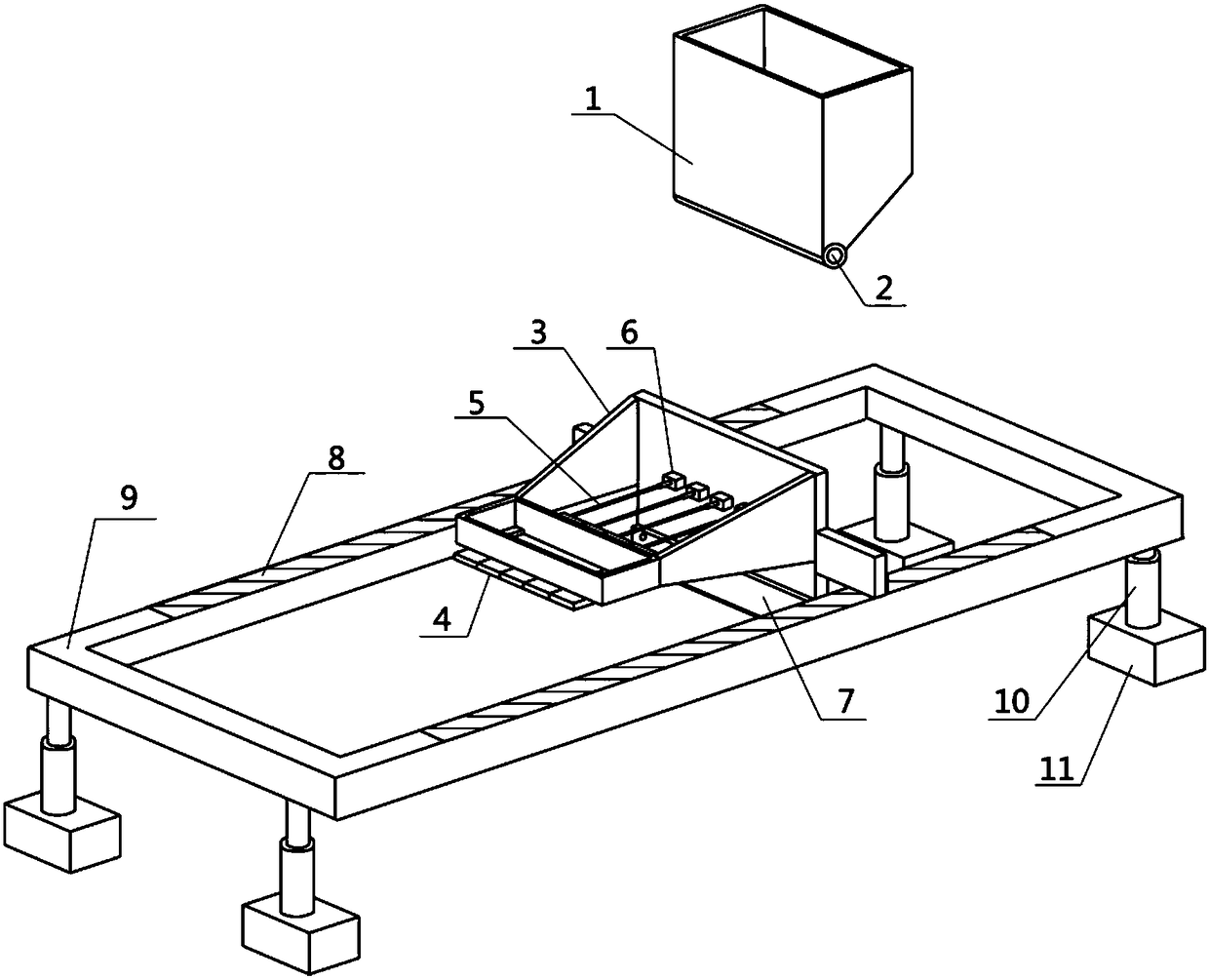

[0027] Such as figure 1 As shown, a powder spreading device provided by the example of the present invention includes a powder storage component, a selective area powder spreading component and an auxiliary moving component;

[0028] The powder storage component includes a powder storage cabin 1 and a rotating shaft 2, which are used to store metal powder, and provide metal powder for the selective powder coating component during the laser additive manufacturing process of metal parts; as figure 2 As shown, the powder storage cabin 1 is installed above the working cavity of the laser additive equipment, and its lower part is in the shape of a funnel that gradually shrinks in volume; the bottom of the funnel has a powder outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com