Welding smoke generator, welding production line and processing technology including the generator

A welding production line, smoke generator technology, applied in welding production line and processing technology, welding flux smoke generator field, can solve the problems of increasing production cost, environmental pollution, secondary pollution of electronic components, restricted use, etc., to reduce smoke emission Out, avoid secondary pollution, avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

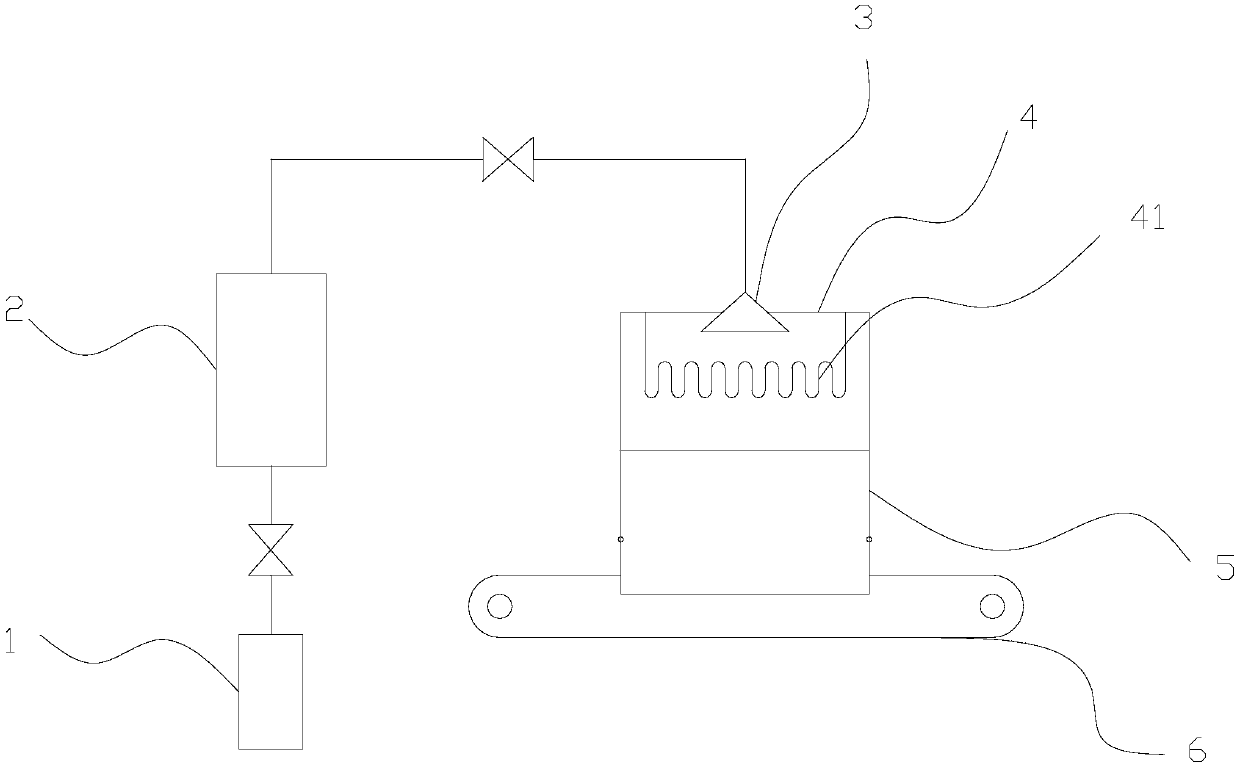

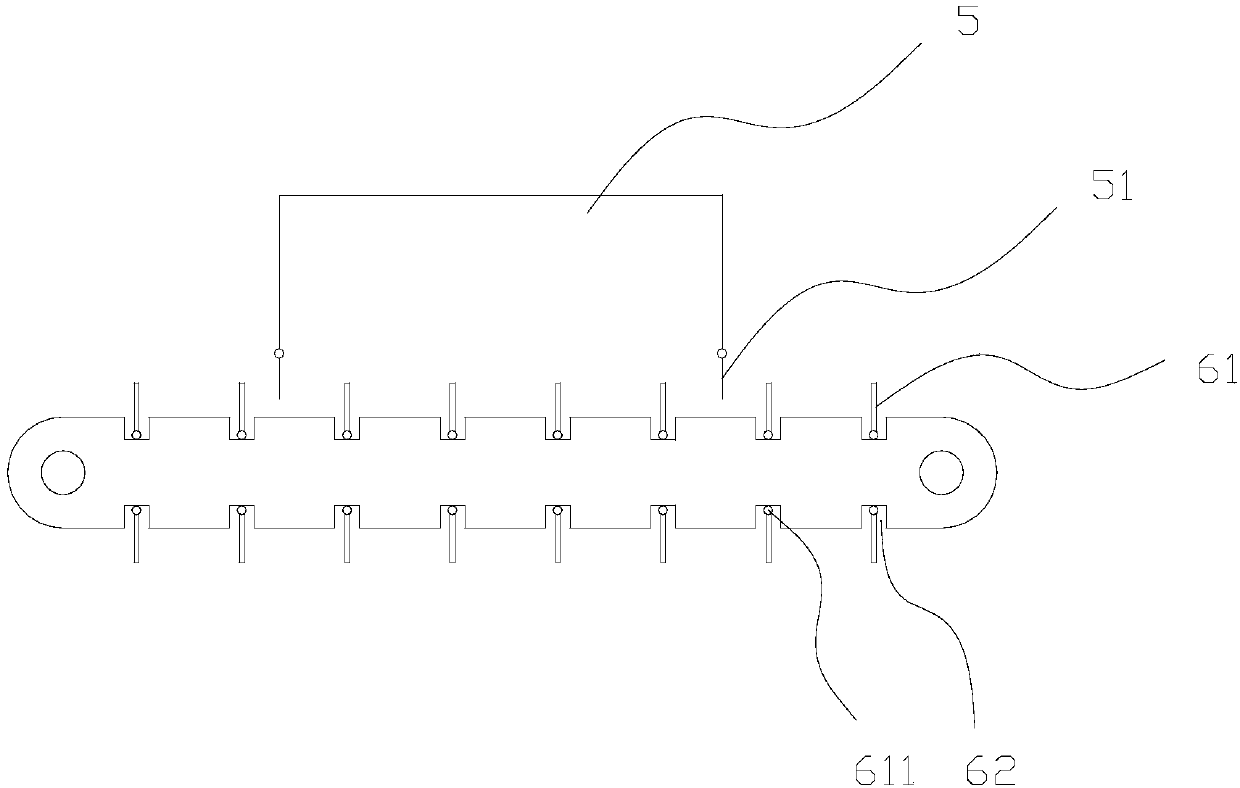

[0025] Such as figure 1 As shown, the flux smoke generator includes a gas source 1, a liquid flux tank 2, an atomizing nozzle 3 and a heating device 4 connected in sequence. The gas source 1 is provided with an air outlet valve and an air inlet valve, and the air outlet valve passes through The pipeline is connected to the liquid flux tank 2, the outlet valve is opened, the gas overflows from the gas source 1 to the liquid flux tank 2, and the liquid flux is taken out of the liquid flux tank 2; the air inlet valve is convenient for the lack of gas in the gas source 1 The gas is supplemented from the outside; the liquid flux tank 2 is provided with a liquid inlet valve and a liquid outlet valve, the liquid outlet valve is opened, and the gas and liquid overflow from the liquid flux tank 2 to the subsequent process; when the liquid flux tank 2 When the amount of inter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap