FFS radome machining method and machining device based on multi-degree-of-freedom laser robot

A processing method and a processing device technology are applied in the field of the FSS radome processing method and processing device to achieve the effects of reducing RCS, simplifying the process and ensuring design performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

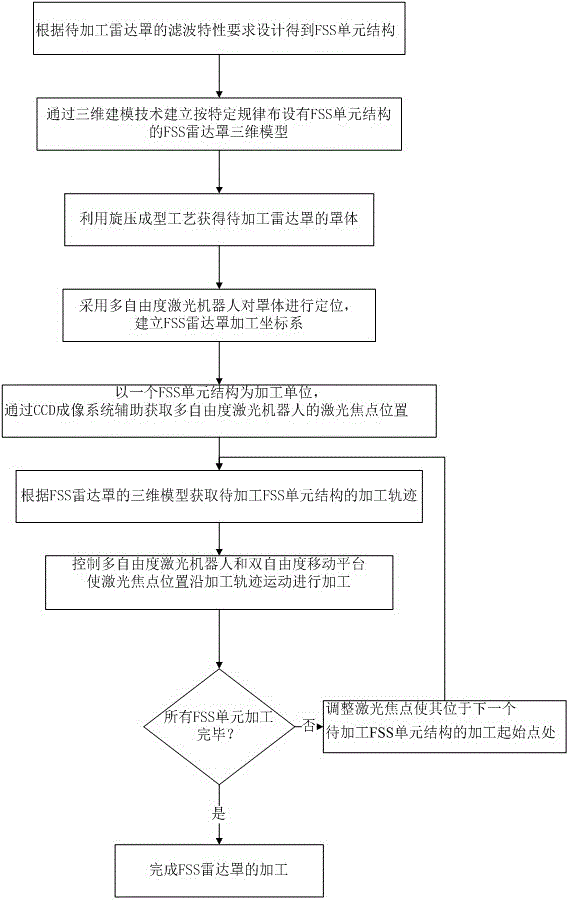

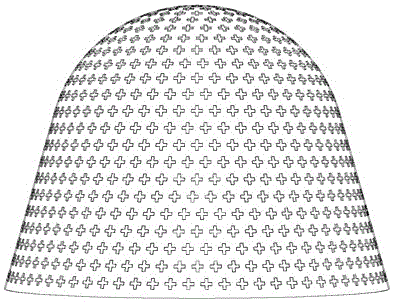

[0038] Such as Figure 1~4 As shown, a kind of FSS radome processing method based on multi-degree-of-freedom laser robot of the present embodiment comprises the following steps:

[0039] Step S1: Design the FSS unit structure according to the filtering characteristic requirements of the radome to be processed, and establish a three-dimensional model of the FSS radome with N FSS unit structures arranged according to specific rules through three-dimensional modeling technology, wherein N is a positive integer greater than 1;

[0040] Step S2: using a spinning forming process to obtain the radome body to be processed;

[0041] Step S3: Fix the radome body to be processed, use a multi-degree-of-freedom laser robot to position the radome body, and establish the FSS radome processing coordinate system;

[0042] Step S4: Take an FSS unit structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com