Adjusting device for straight seam splicing welding of pre-deformation thick plate and welding method thereof

A technology for adjusting devices and welding methods, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of high cost, large deformation force, complex and huge structure, etc., and achieves low cost, elimination of welding deformation, and wide adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

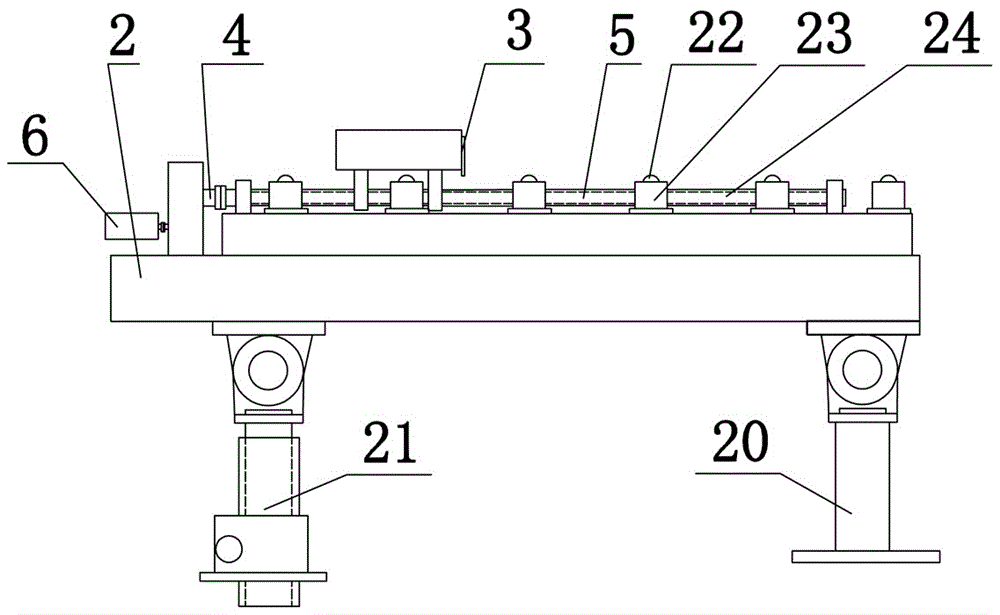

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

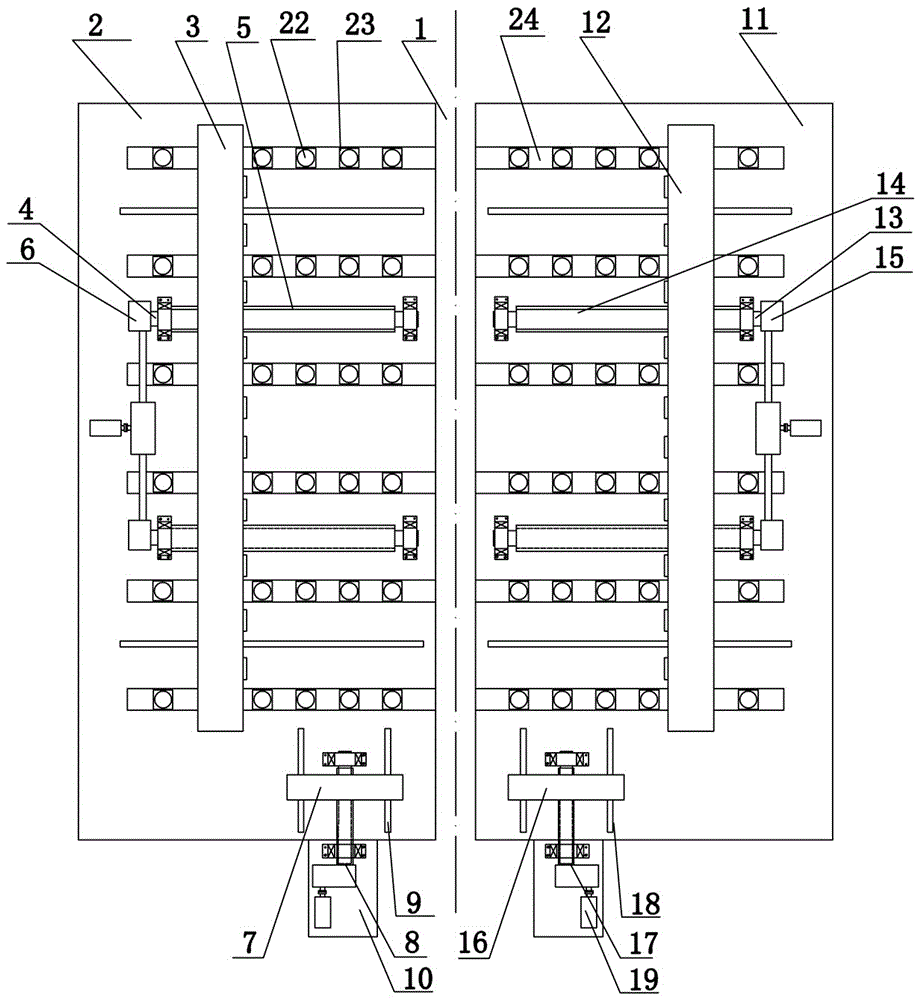

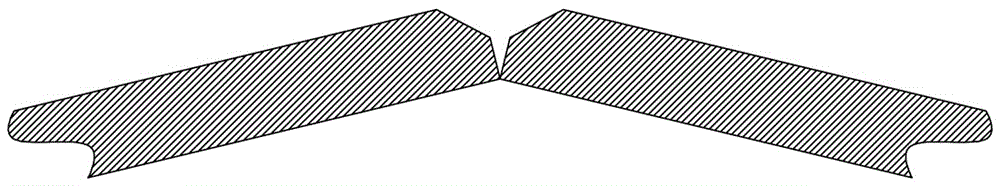

[0031] A pre-deformed thick plate straight seam splicing welding adjustment device, including a welding area 1, a left platform 2 and a right platform 11; the welding area 1 is in the shape of a straight line; the left platform 2 is adjacently arranged on the left side of the welding area 1 side; the right platform 11 is adjacently arranged on the right side of the welding zone 1, and symmetrically arranged with the left platform 2;

[0032] The left platform 2 is provided with a left centering push plate 3 and a left end push plate 7; the left centering push plate 3 is strip-shaped and arranged parallel to the welding zone 1; the left end push plate 7 is set On the side of the left centering push plate 3, and vertical to the welding zone 1; the left end push plate 7 is located between the left centering push plate 3 and the welding zone 1;

[0033] The righ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com