Automatic assembly machine for relay

An automatic assembly machine and relay technology, applied in the direction of relays, circuits, electrical components, etc., can solve the problems of not being able to meet the needs of modern production and the low efficiency of manual assembly by staff, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0045] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and the drawings, and the content mentioned in the embodiments does not limit the present invention.

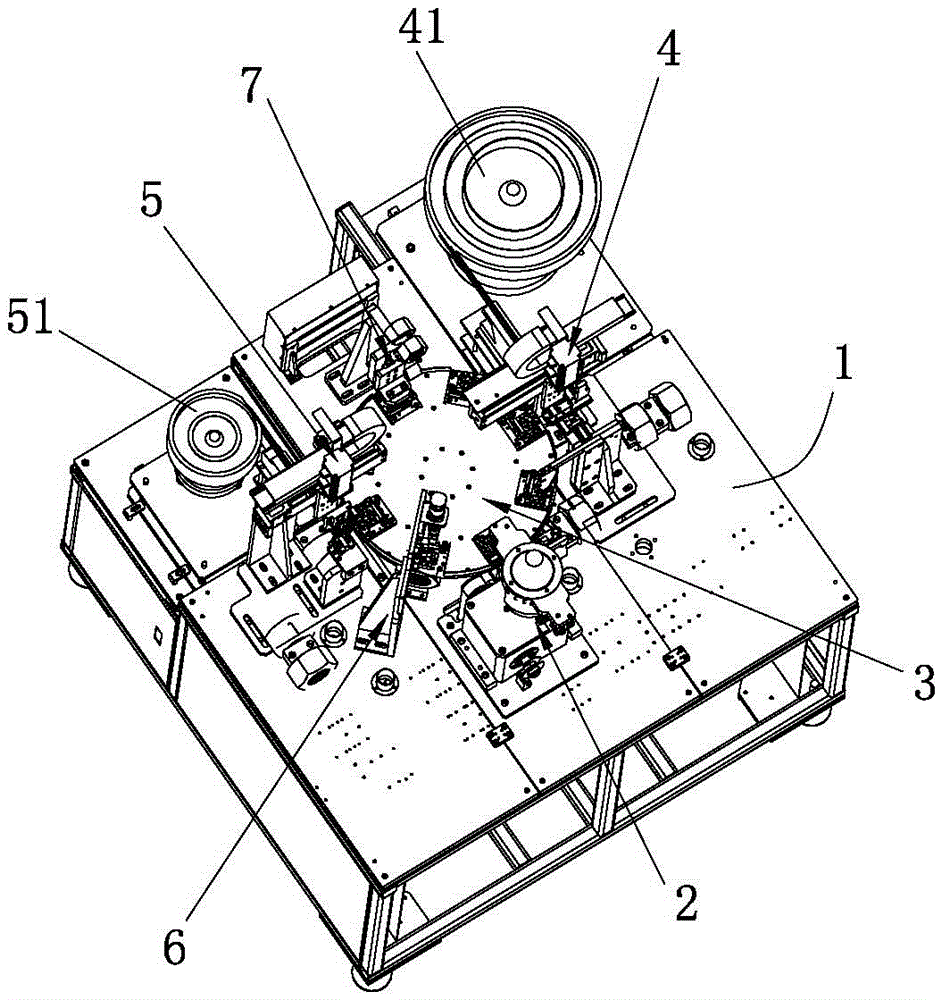

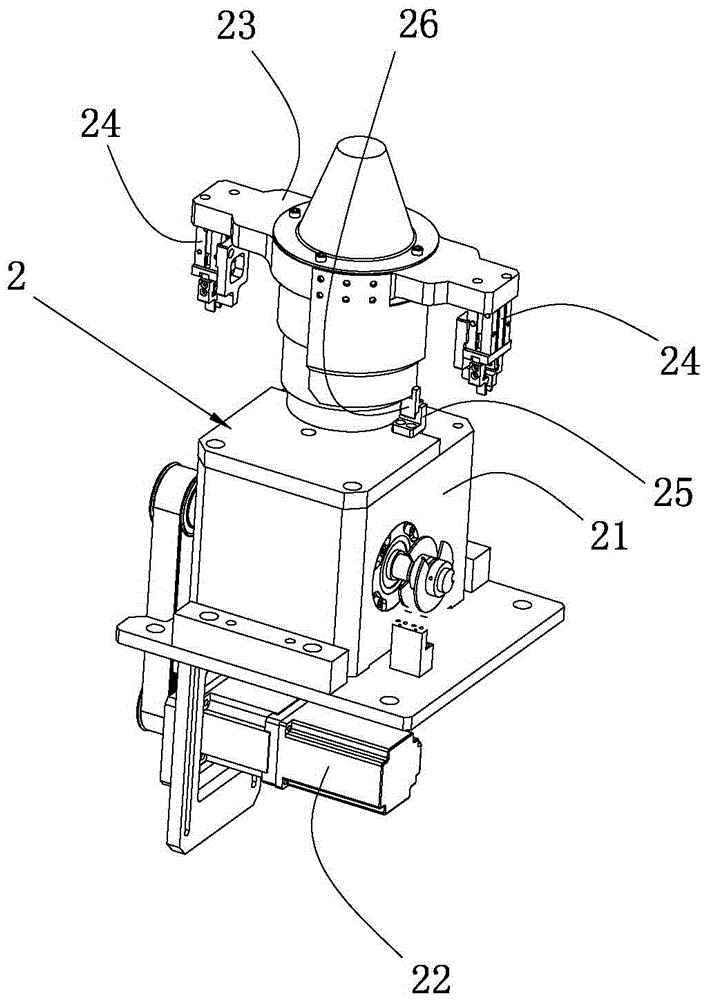

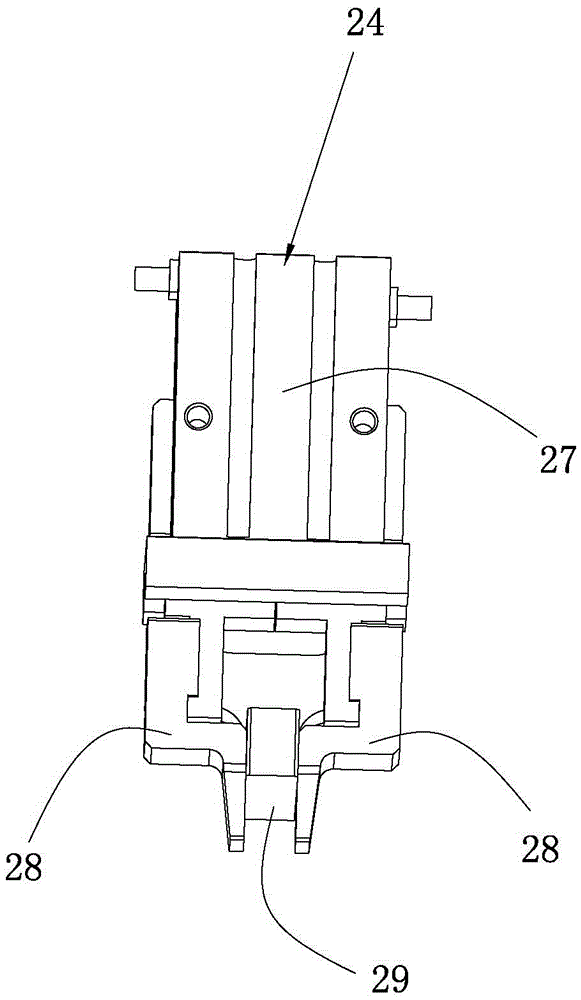

[0046] See Figure 1 to Figure 5 , An automatic assembling machine for relays of the present invention includes a frame 1, a first manipulator 2, a splitter mechanism 3, a second manipulator 4 and a second manipulator 4 that are mounted on the frame 1. A feeding mechanism 41. In this embodiment, the first feeding mechanism 41 is used to supply the armature of the relay to the second manipulator 4. The first manipulator 2 and the second manipulator 4 are arranged around the divider mechanism 3, and the divider mechanism 3 is arranged There is a rotatable turntable 31. The turntable 31 is approximately a circular flat plate. The turntable 31 is provided with a receiving groove 32 that cooperates with the first manipul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap