Efficient equipment for pressing bearing into rear axle

A technology for rear axle and bearing, which is applied in the field of high-efficiency press-in bearing equipment to the rear axle, can solve the problems of low production efficiency, damage to the mounting plate, and hammer injury, so as to improve processing efficiency, improve press-in quality, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

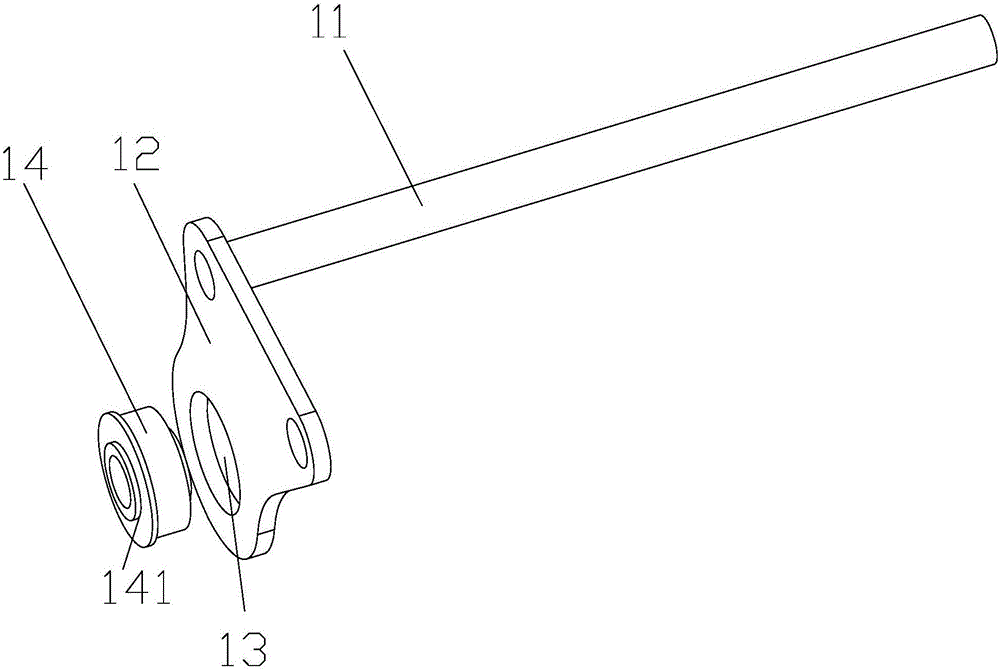

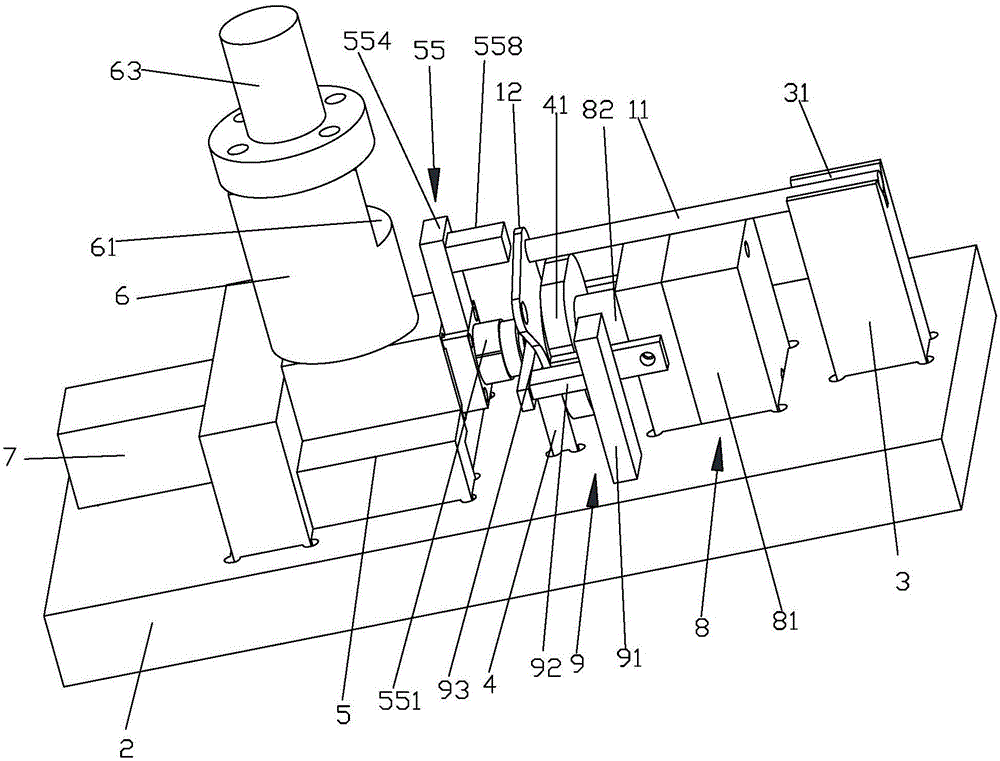

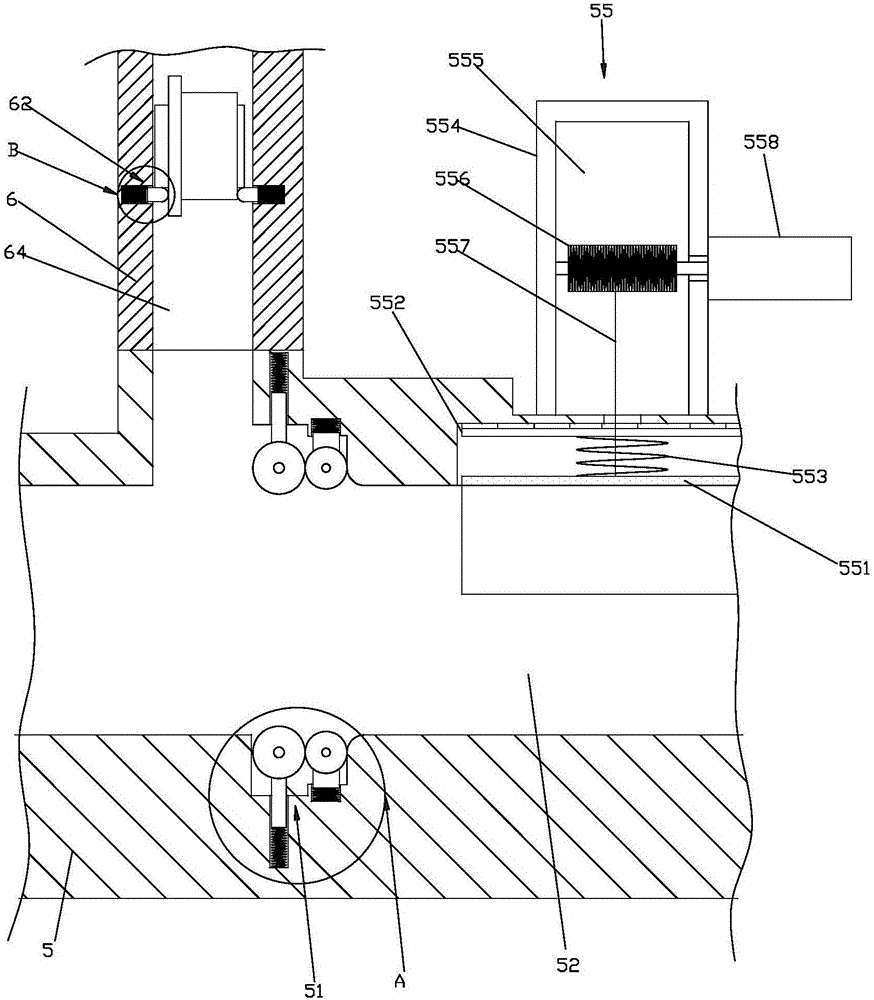

[0049] Such as figure 1 as well as figure 2 As shown, the present embodiment provides a high-efficiency press-in bearing device to the rear axle, including:

[0050] work platform 2;

[0051] The resting seat 3 is arranged on the surface of the working platform 2, and the surface of the resting seat 3 is concave to form a resting groove 31, and the axle body for placing the rear axle in the resting groove 31 is away from the end of the mounting plate;

[0052] The support seat 4 is arranged on the surface of the working platform 2 and is located beside the seat 3. The surface of the support seat 4 is provided with a plate groove (not shown) for placing the mounting plate. When installing, the mounting plate is far away from the shaft body. The edge is placed in the plate groove, and the side of the support seat 4 close to the seat 3 is provided with a pressure bearing plate 41 that supports the mounting plate from the horizontal direction;

[0053] The feeding seat 5 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com