Hydraulic tensioner and tensioning method thereof

A technology of hydraulic stretcher and tie rod, applied in the field of stretcher, can solve the problems of inconvenient oil supply again, bulky pump station, reduced work efficiency, etc., and achieve the effect of preventing excessive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

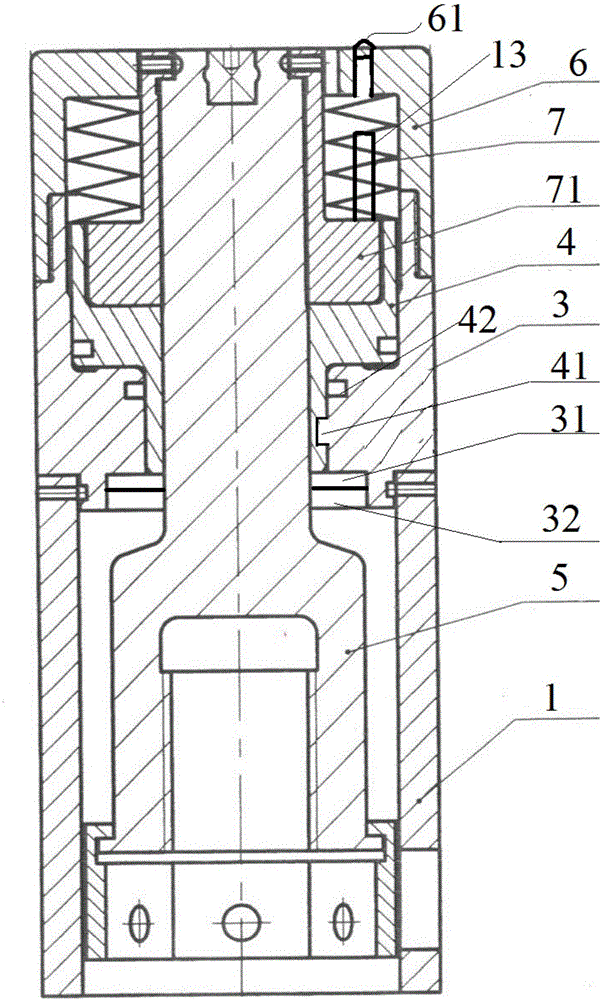

[0058] A hydraulic stretcher in this embodiment includes a base 1, an oil cylinder 3, a piston 4, a pull rod 5 and an end cover 6, the base 1 is located at the lower part of the oil cylinder 3, the pull rod 5 is arranged in the oil cylinder 3, and the diameter of the oil cylinder 3 and the pull rod 5 To be provided with the piston 4 that cooperates with both, the top of the piston 4 is provided with a screw sleeve 71, the end cover 6 is fixed on the upper surface of the oil cylinder 3, and a spring 7 is evenly arranged between the end cover 6 and the screw sleeve 71, and also Including a pumping station 31 and a fuel tank 32, the pumping station 31 and the fuel tank 32 are located at the bottom of the oil cylinder 3, the fuel tank 32 communicates with the oil cylinder 3 through the pumping station 31, and the pumping station 31 is provided with a pressure rod, a high-pressure relief valve and an unloading valve.

Embodiment 2

[0060] A hydraulic extender in this embodiment is similar to Embodiment 1, wherein both the oil tank 32 and the oil cylinder 3 are annular, and the upper part of the ejector rod 5 passes through the annular hole in the middle of the oil tank 32 and the oil cylinder 3, and the oil tank 32 is located in the oil cylinder 3. In the lower part, the oil tank 32 communicates with the oil cylinder 3 through the pump station 31. The pump station 31 is located on the side of the oil tank 32. On the pump station 31, there are pressure rods, pressure gauges, high-pressure relief valves and unloading valves, opposite to the pump station 31. The side of the base 1 is provided with through holes matching the shape of the pressure rod, high pressure relief valve, pressure gauge and unloading valve.

Embodiment 3

[0062] A hydraulic stretcher in this embodiment is similar to Embodiment 1 or 2, wherein it also includes a gear box 14, the gear box 14 is located on the side of the base 1, and the gear box 14 includes a gear one 141, a gear two 142 and Gear 3 143 , gear 1 141 , gear 2 142 and gear 3 143 mesh sequentially. The top of gear 141 is provided with a bolt hole, and gear 3 143 is in contact with the pre-tightening nut in base 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com