Device used for self-grinding repair of numerical control machine tool spindle conical hole

A technology of CNC machine tools and spindles, which is applied in the direction of grinding drive devices, grinding machine parts, grinding automatic control devices, etc., which can solve the problems of long downtime and heavy workload, and achieve convenient operation and high self-repair efficiency , Promoting good prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

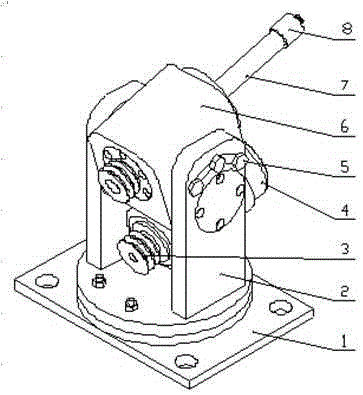

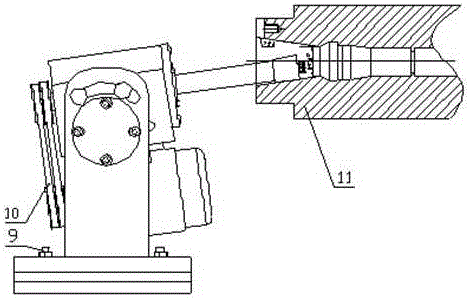

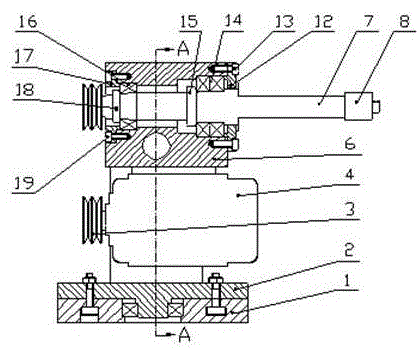

[0018] Aiming at the problems existing in the prior art, the invention provides a device for self-grinding repair of the taper hole of the spindle of a numerically controlled machine tool. The device for self-grinding and repairing the taper hole of the spindle of a CNC machine tool provided by the present invention has a simple structure and is convenient to operate. It does not need to disassemble the spindle of the machine tool, and the taper hole of the spindle can be repaired by using the CNC programming feed of the machine tool to cooperate with the device, and it is easy to operate. , the cost is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com