Plastic bottle cleaning method

A cleaning method and technology for plastic bottles, which are applied in plastic recycling, recycling technology, metal processing, etc., can solve the problem of heavy labor burden on workers, and achieve the effect of convenient cutting and uniform bottle opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described in detail below through specific implementations:

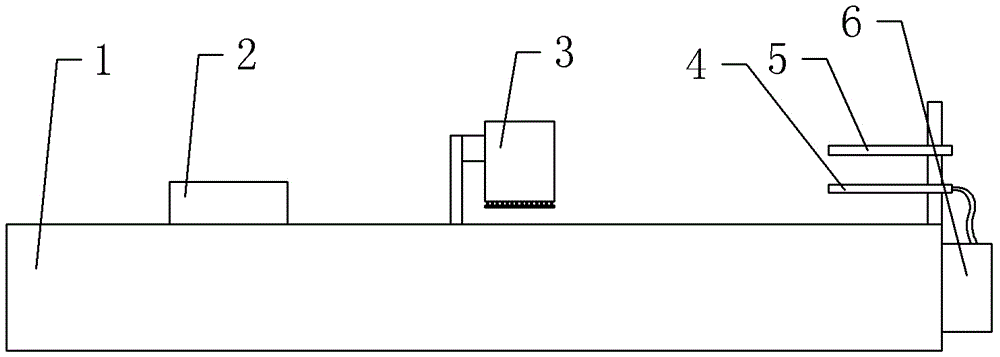

[0017] The reference signs in the drawings of the specification include: water tank 1, cutting mechanism 2, water tank 3, lower plate 4, upper plate 5, and air compressor 6.

[0018] The cleaning method of plastic bottles involves a cleaning device, such as figure 1 As shown, the device includes a water tank 1 and a water pump in the water tank 1 for flowing water. The water tank 1 includes a feed section, a diversion section and a cutting section. The feed section is equipped with a lifting mechanism. The lifting mechanism includes an upper plate 5, a lower plate 4 and a vertical guide rod. The upper plate 5 and the lower plate 4 are both The guide rod is slidingly connected, and the guide rod is welded to the water tank 1. Both the lower plate 4 and the upper plate 5 are in a grid shape. A number of exhaust pipes are arranged on the lower plate 4, and the exhaust pipes are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap