An automatic heat-sealing and cold-cutting device for a plastic film bag making machine

A technology of plastic film and cold cutting device, which is applied in the direction of bag making, packaging, transportation and packaging, etc. It can solve the problems of resource waste, affecting the cutting speed of plastic film, and slowing down the movement speed, so as to improve work efficiency and improve Productivity and resource saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

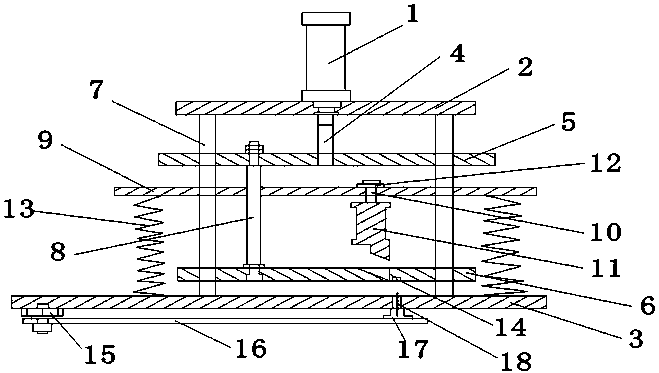

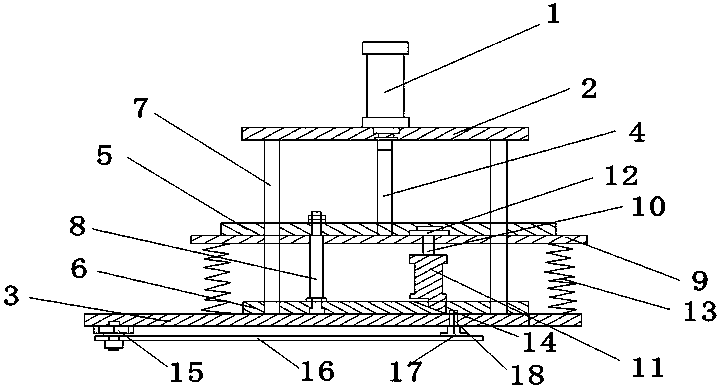

[0018] The reference signs in the drawings of the description include: cylinder 1, upper fixed plate 2, lower fixed plate 3, piston rod 4, upper movable plate 5, lower movable plate 6, guide rod 7, spring suspension rod 8, fixed rod 9, Coupling rod 10, heat sealing knife device 11, nut 12, spring 13, blade slot 14, rotary driver 15, knife rest swing bar 16, knife rest 17, blade 18.

[0019] The embodiment is basically as attached figure 1 Shown: an automatic heat-sealing and cold-cutting device for a plastic film bag making machine, including a cylinder 1, an upper fixing plate 2 and a lower fixing plate 3, the cylinder 1 is fixed at the center of the upper end of the upper fixing plate 2, and the piston of the cylinder 1 Rod 4 is also positioned at the center of last fixed plate 2, and the two ends of last fixed plate 2 are provided with guide rod 7, and the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com