100% low-floor trolley car non-powered bogie frame

A tram, non-power technology, used in bogies, railway car body parts, transportation and packaging, etc., can solve problems such as stress concentration, frame failure, and many connection welds, and achieve beautiful appearance, reliable performance, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

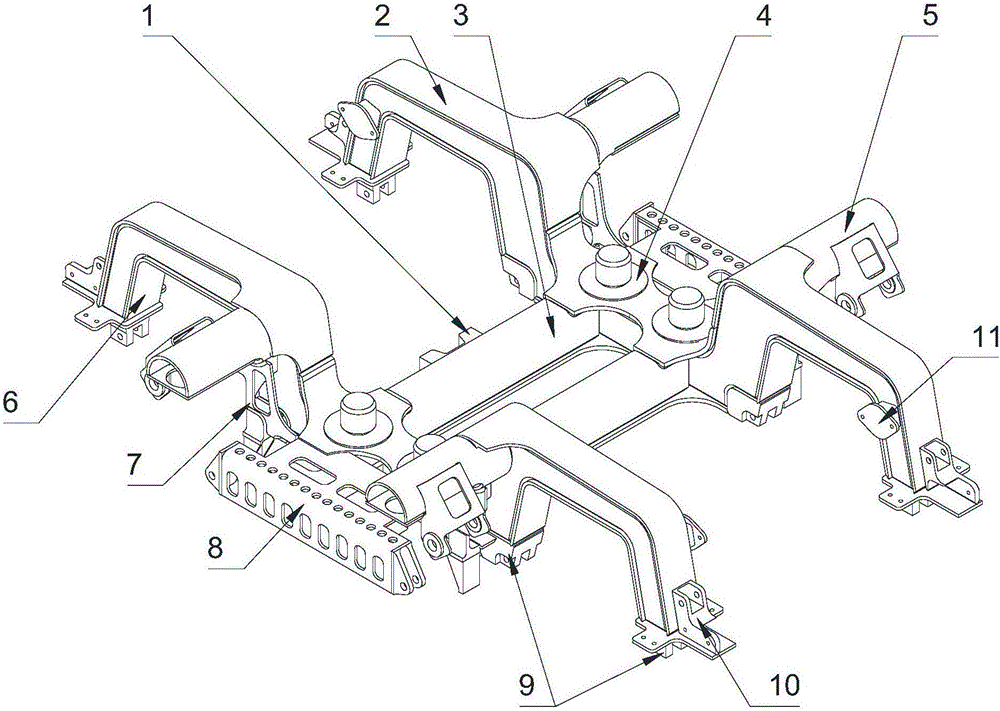

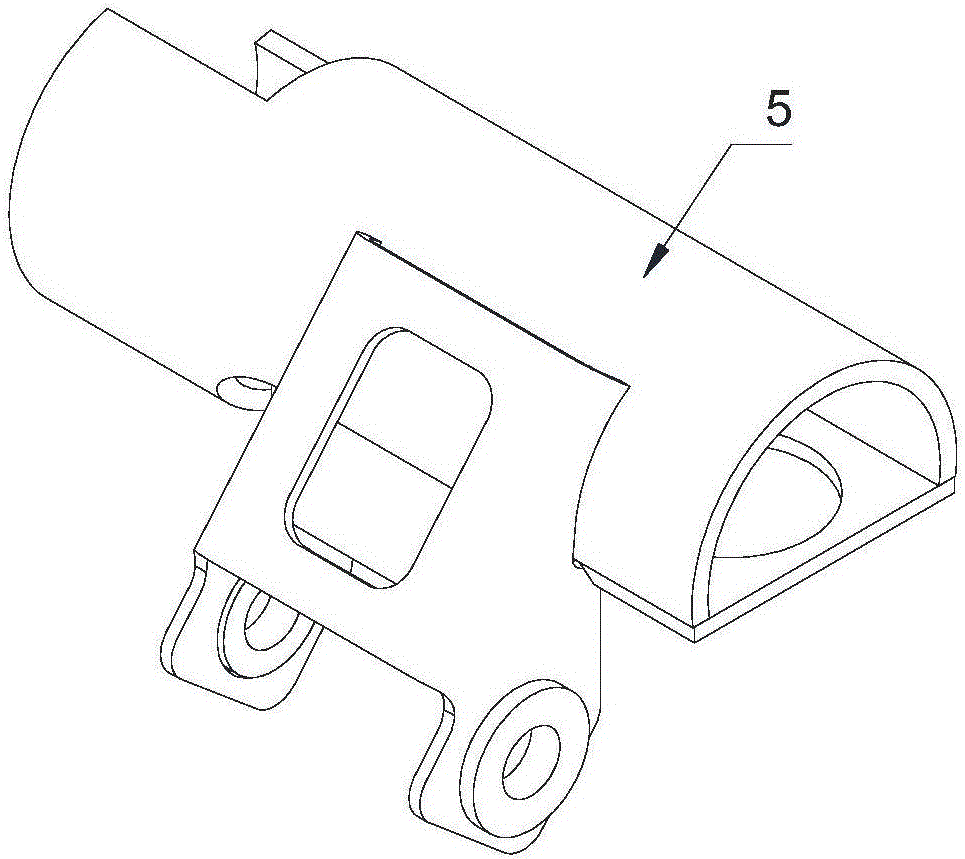

[0020] A 100% low-floor tram non-power steering frame frame, such as figure 1 Shown, including: traction rod mounting seat 1, side beam 2, cross beam 3, secondary spring seat 4, brake caliper seat 5, primary suspension device mounting seat 6, magnetic rail brake guide seat 7, brake caliper Tie rod seat 8, axle box tie rod seat 9, transverse and vertical shock absorber mounting seat 10, transverse stop seat 11, etc., of which:

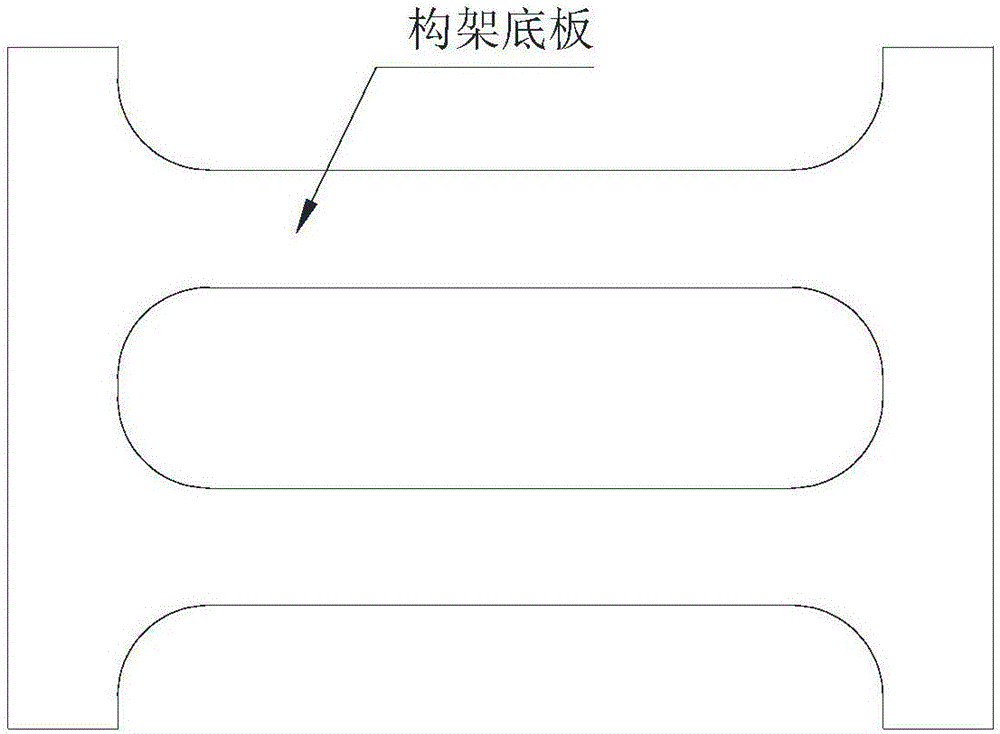

[0021] The overall structure of the non-powered bogie is H-shaped, the bottom plate is a whole plate, the side beam 2 and the cross beam 3 are fixed on the bottom plate by welding, and the cross beam is welded to the side beam by splicing.

[0022] The side beam 2 is a box beam structure formed by welding the upper and lower cover plates and the left and right webs. The middle part of the side beam is concave, and the concave middle part of the two side beams is connected by the cross beam 3, and the middle concave of each side beam Equipped with secondary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com