Remote control method for multi-channel caterpillar track device

A multi-channel, crawler technology, applied to tracked vehicles, control devices, transportation and packaging, etc., can solve the problems of complex chassis system and control method, large damage to the flatness of paddy fields, and increase the weight of the whole machine, so as to optimize the underlying structure of the machine , reduce driving labor intensity, improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

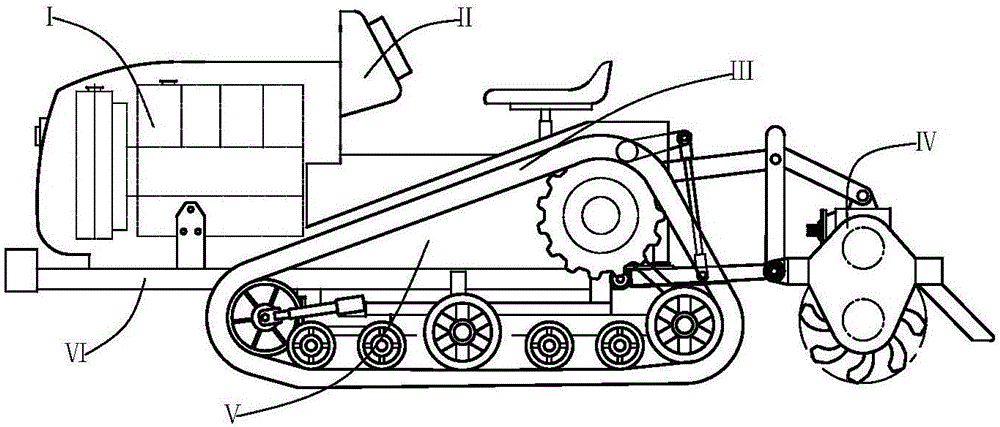

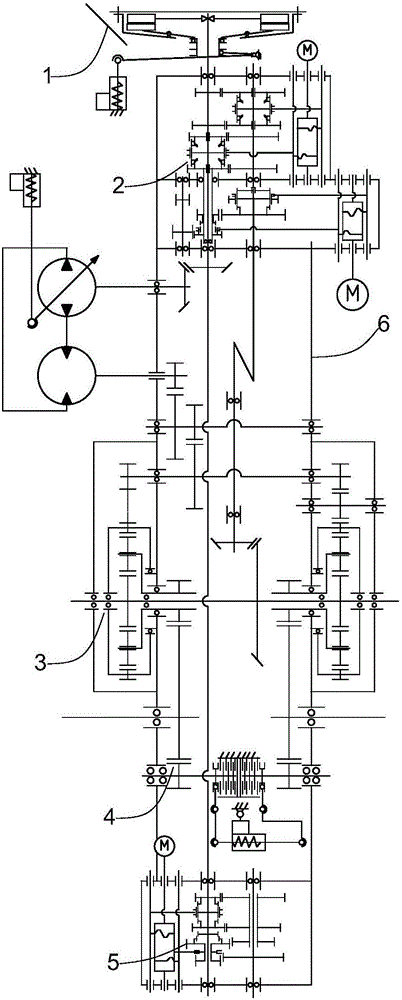

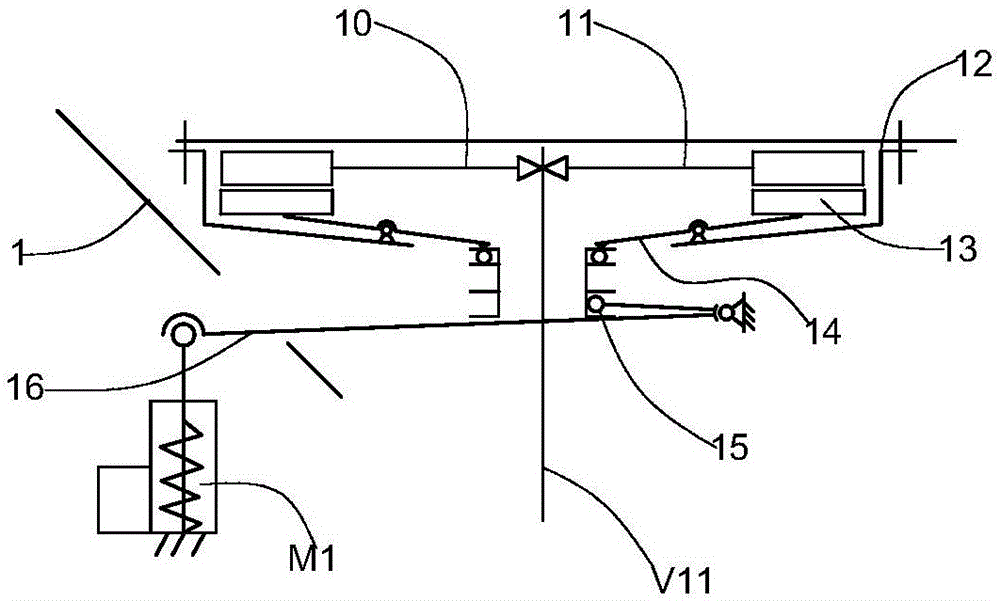

[0038] see Figure 1 ~ Figure 2 The remote control method for multi-channel crawler equipment adopts the remote control device for multi-channel crawler equipment to implement remote control, and the remote control VIII sends operation instructions to the controller VII, and the controller VII transmits the operation instructions to various mechanisms connected to the controller VII for implementation. Specific operation, the hydrostatic continuously variable transmission device H rotates forward, the output gear D22 of the hydrostatic continuously variable transmission device drives the intermediate shaft driven gear D23 to rotate, the intermediate shaft driven gear D23 drives the intermediate shaft D12 to rotate, and the intermediate shaft D12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com