Material taking plate, PCB (printed circuit board) overlaying device and PCB riveting device

A PCB board and reclaiming board technology, applied in thin material handling, transportation and packaging, separation of objects, etc., can solve the problems of inconvenient grasping, easy to scratch the surface of the circuit board, etc., and achieve simple structure, convenient control, and division of labor. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

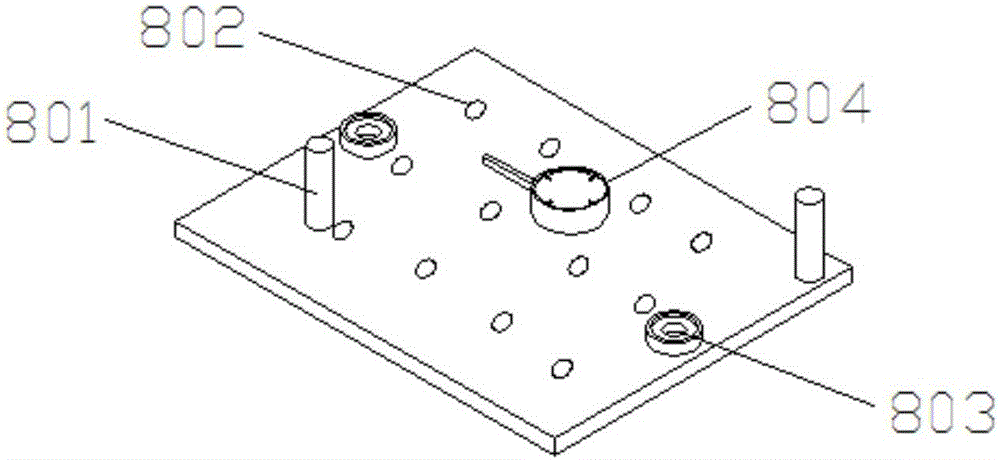

[0043] Such as Figure 1-4 As shown, the pick-up plate 800 provided in this embodiment includes: a suction cup, and a plurality of vacuum suction holes 802 located on the suction cup; the upper surface of the suction cup is also provided with a telescopic pull rod and a position detector, and the telescopic pull rod can stretch toward the lower surface of the suction cup , the position detector is electrically connected to the control system; the position detector is used to detect the position of the suction cup and transmit the signal to the control system, and the control system is used to control the extension of the telescopic rod to the lower surface of the suction cup to separate the suction cup from the material plate it absorbs.

[0044]It should be pointed out that, when placing the inner circuit board and the resin sheet (prepreg PP) on the pick-up plate 800 provided in this embodiment, when the vacuum is broken, there may be adhesion between the suction cup and the ...

Embodiment 2

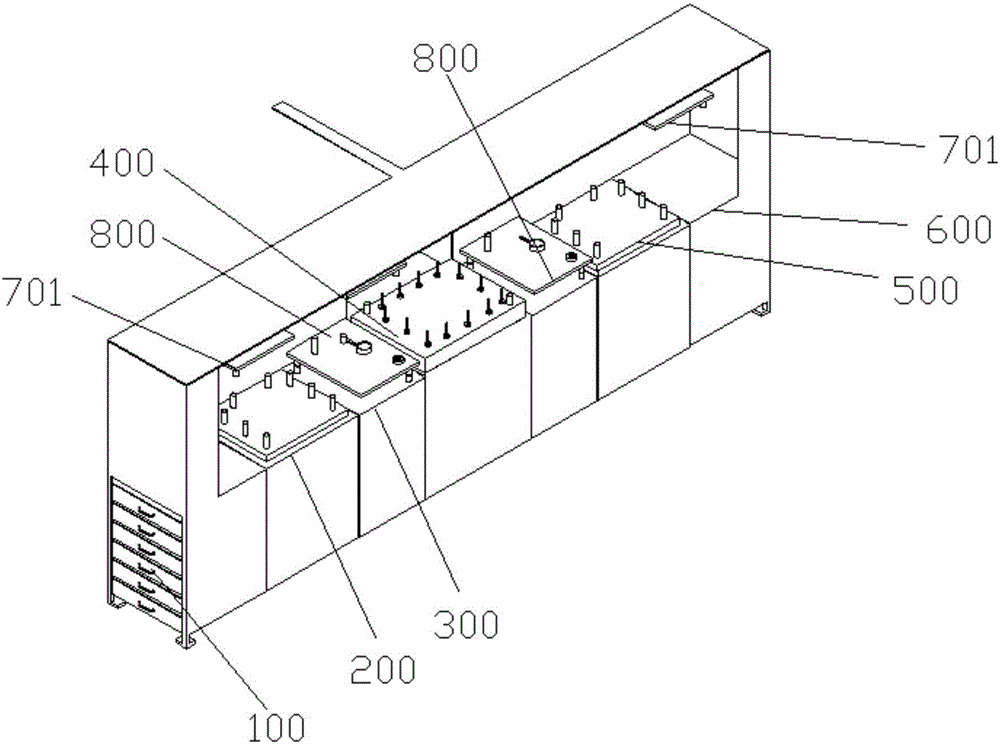

[0053] On the basis of Embodiment 1, the PCB board stacking device provided in this embodiment includes two picking plates 800, two first picking trays 701 and a PCB stacking mechanism; two picking plates 800 and The two first retrieving trays 701 are arranged above the PCB stacking mechanism through a grabbing mechanism (not shown); the grabbing mechanism is controlled by a control system.

[0054] Among them, the first material picking tray 701 provided in this embodiment has roughly the same structure as the material picking plate 800, mainly including a suction cup and a number of vacuum suction holes 802 on the suction cup; The retracted telescopic rod and the position detector are electrically connected to the control system; the position detector is used to detect the position of the suction cup and transmit signals to the control system, and the control system is used to control the extension of the telescopic rod and hold against the material plate so that The suction...

Embodiment 3

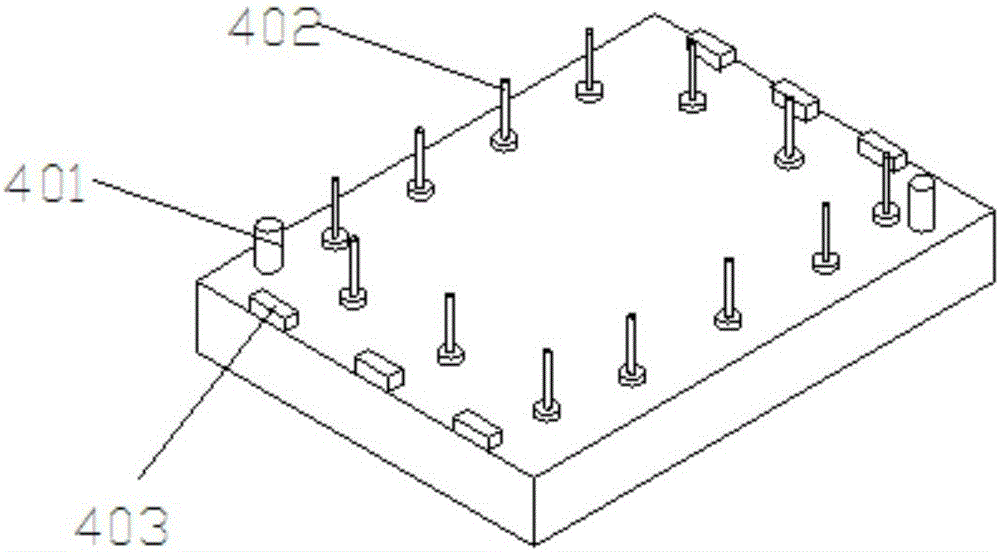

[0064] On the basis of Embodiment 2, the PCB board riveting device provided in this embodiment includes a PCB board stacking device, a riveting machine 900 and a second retrieving tray 702; the riveting machine 900 and the second retrieving tray 702 are respectively set On both sides of the PCB board stacking mechanism; the riveting machine 900 is connected with the PCB board stacking mechanism through a screw 901 to transport the PCB board to the riveting machine 900; the second feeding tray 702 is set at the unloading position, and the unloading position is connected with the PCB The plate stacking mechanism is connected.

[0065] Specifically, the riveting machine 900 is connected to the loading table 400 through a screw 901 or a slider to transport the PCB board to the riveting machine 900; Due to the setting of the PCB board stacking device, the PCB board riveting device has all the advantages of the above-mentioned PCB board stacking device and the picking plate 800. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com