Core taking mechanism for roll paper core recovery

A technology of web and paper core, applied in the field of coring mechanism for web core recycling, can solve the problems of inaccurate positioning of paper core, high cost, waste of cost and work efficiency, so as to improve work efficiency and core removal Variety of specifications and precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Now, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

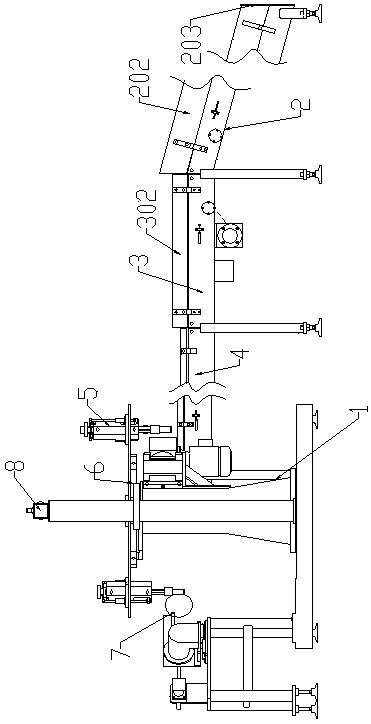

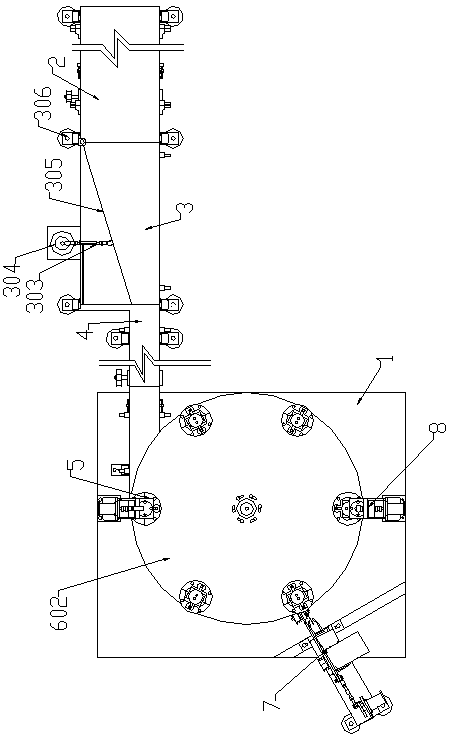

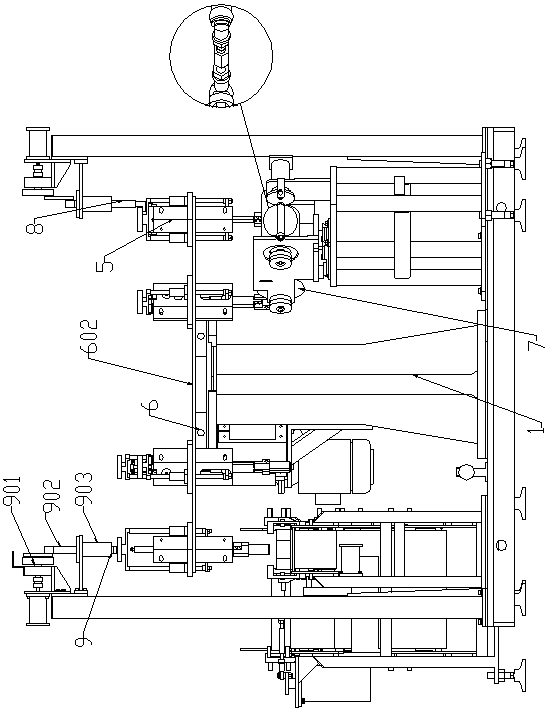

[0038] Such as Figure 1-3 As shown, the coring mechanism for web paper core recovery of the present invention includes an automatic rewinding part 2 fixed on the frame 1, an automatic arrangement part 3, an automatic speed regulation part 4, a coring part 5, and a negative pressure part 6 , the paper-cutting shedding part 7, the core-removing reset part 8, the coring pressing part 9, wherein the discharge end of the automatic rolling part 2 is connected to the feeding end of the automatic arrangement part 3, and the automatic speed regulation part 4 is connected to the automatic arrangement part 3 At the discharge end, the coring part 5 is fixed on the negative pressure part 6 above the discharge end of the automatic speed regulating part 4, the paper cutting part 7 is arranged on one side of the core part 5, the core removal reset part 8, the core T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com