Hoisting method for nuclear power station containment steel liner module

A nuclear power plant containment and hoisting method technology, applied in the field of nuclear power plant construction, can solve the problems of eccentric module gravity, weak variable cross-section structure, and inability to realize hoisting of steel-lined large thin-walled cylindrical structure modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] like Figure 1-13 As shown, a nuclear power plant containment steel lining module hoisting method, including steps:

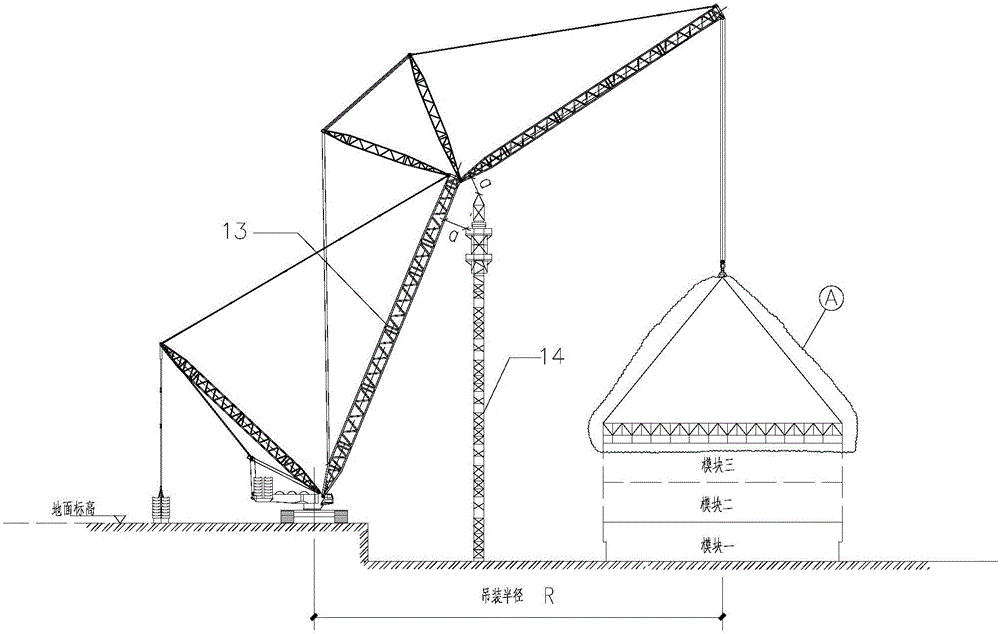

[0049] Step 1: If figure 1 As shown, select the lifting equipment, use the existing domestic large-scale crawler crane to hoist 13, select reasonable crane working conditions, test and verify the bearing capacity of the foundation of the crawler crane hoisting route, or carry out necessary reinforcement treatment, and ensure that the module hoisting process is consistent with the The safe distance of the surrounding construction; remove all obstacles in the space where the module hoisting passes, and adjust the surrounding construction tower crane 14 to avoid the hoisting and rotating area of the heavy machine hoisting 13.

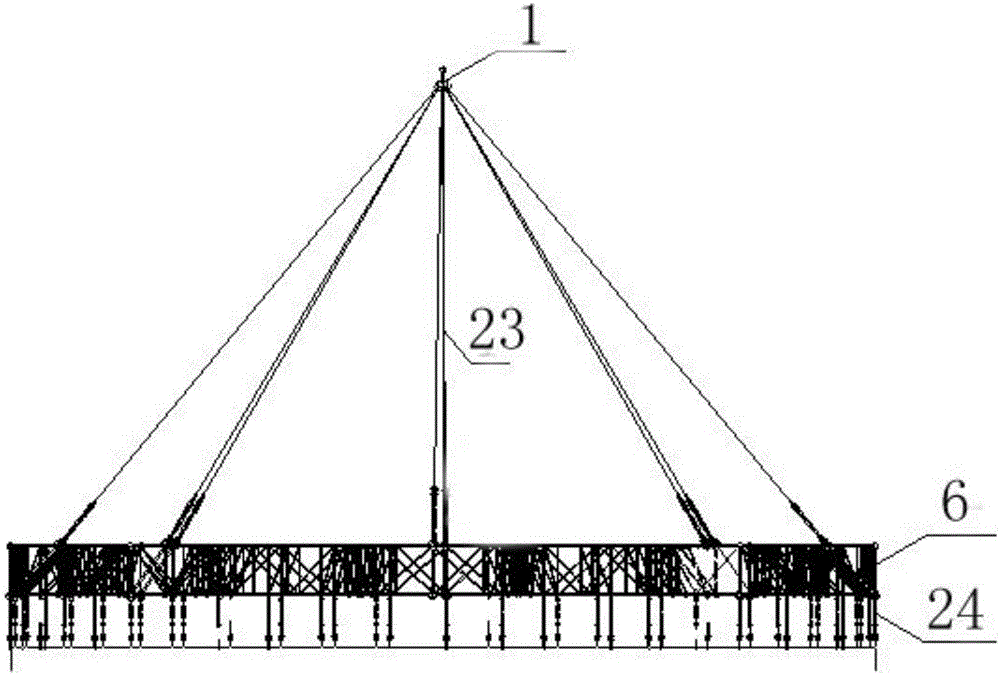

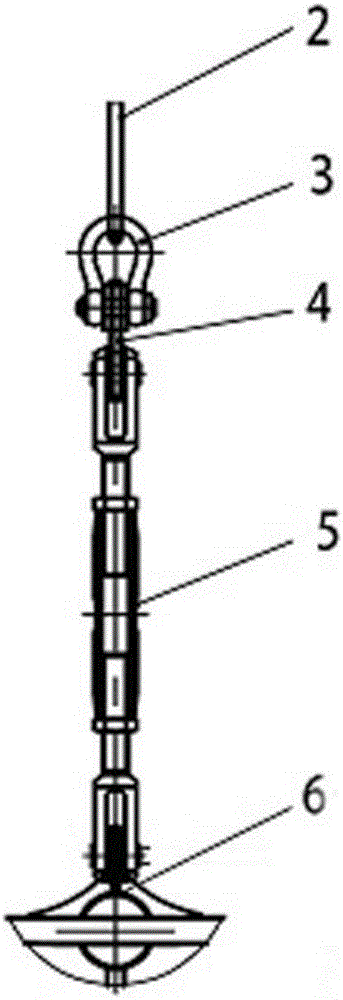

[0050] Step 2: If Figure 2-4 As shown, in combination with the characteristics of module one, module two and module three and the lifting equipment design module sling system, the lifting tool is easy to assemble and disassemble...

Embodiment 2

[0060] like Figure 1-13 As shown, a nuclear power plant containment steel lining module hoisting method, before hoisting, the ground bearing capacity of the crane hoisting 13 travel route is verified and necessary reinforcement is performed, all obstacles in the space passed by the module hoisting are removed, and the tower crane 14 is adjusted to avoid Heavy machinery hoisting 13 hoisting rotating area.

[0061] Hoist the crane 13 and drive to the lifting position of the module, follow the attached Figure 1-4 As shown, the module sling system is assembled and connected; the crane hoist 13 travels to the module hoisting position.

[0062] Start the hoisting 13 of the heavy machine, complete all hoisting actions according to the formal hoisting action flow, and measure whether there are obstacles within the radius of 25m from the center of the crane hook 1 at the same time, and remove them.

[0063] According to attached Image 6 , 7 , 8 and 13 add the circumferential lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com