Variable medium layer sewage treatment oil-water separator

A technology for oil-water separator and sewage treatment, applied in liquid separation, separation method, immiscible liquid separation, etc., can solve the problems of low separation efficiency, unattainable purification rate, long time consumption, etc. The effect of improving efficiency, large internal processing space, and internal structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

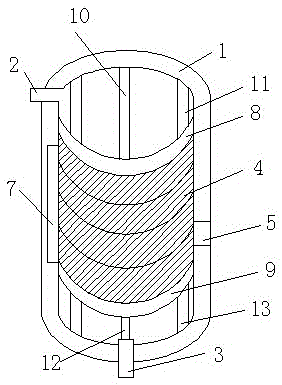

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] As shown in the accompanying drawings, the present invention improves the overall structure on the basis of the traditional separator, especially optimizes the structure of the filter medium layer. For different oil-water separations, different medium filtration is required, and its filtration speed and The purification rate is one aspect, and the full utilization of the filter medium layer also needs to be considered. The structure of the filter medium layer of the present invention is different from the square and flat pattern of the existing filter medium. The surface that first contacts with oil and water is set to be non-planar, which can be a downwardly concave arc surface or an upwardly convex arc surface. When controlling the filtration rate of the filter medium layer, the oil and water are evenly distributed on the surface of the filter medium layer, withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com