Simple method for retarding densification of float sludge in sludgeharbor

A silt, floating mud technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of heavy vertical increase of floating mud, difficulty in normal navigation of ships, and loss of navigability. and other problems, to achieve the effect of reducing the frequency of dredging, low price, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A simple method for delaying the compaction of floating mud in silty ports, the specific steps are as follows:

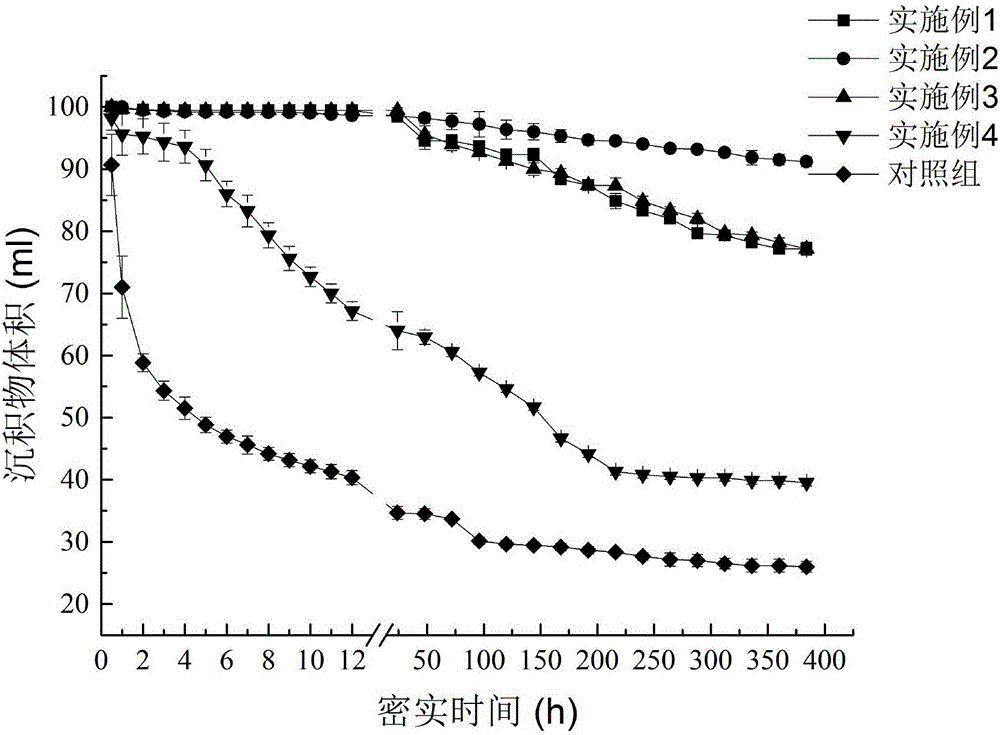

[0020] Add methanol to the floating mud with a density of 1050g / L in a ratio of 12% (V / V), place the mixture of floating mud and methanol in a 500ml Erlenmeyer flask, and mix with an air shaker (rotating speed is 180r / min) 5 Two days later, take the floating mud sample and put it in a 100mL measuring cylinder, record the change trend of the sediment volume over time, and observe the effect of delaying the compaction of the floating mud.

[0021] Control group: Weigh the floating mud sample and dilute it with water to make the final density 1050g / L, and shake it with an air shaker (180r / min, 2h). Take the floating mud sample and put it in a 100mL measuring cylinder, record the change trend of the sediment volume over time, and observe the effect of delaying the compaction of the floating mud.

Embodiment 2

[0023] A simple method for delaying the compaction of floating mud in silty ports, the specific steps are as follows:

[0024] Add methanol to the floating mud with a density of 1050g / L at a ratio of 4% (V / V), place the mixture of floating mud and methanol in a 500ml Erlenmeyer flask, and mix with an air shaker (rotating speed is 180r / min) 2 sky. Add methanol in the floating mud again in a ratio of 4% (V / V), continue to mix (rotating speed is 180r / min) for 2 days, then add methanol in the floating mud in a ratio of 4% (V / V), Continue to mix (rotating at 180r / min) for 1 day, take a sample of the floating mud and place it in a 100mL measuring cylinder, record the trend of the sediment volume over time, and observe the effect of delaying the compaction of the floating mud.

[0025] Control group: with embodiment 1.

Embodiment 3

[0027] A simple method for delaying the compaction of floating mud in silty ports, the specific steps are as follows:

[0028] Add a mixture of methanol and formic acid to the floating mud with a density of 1050g / L at a ratio of 12% (V / V), and the volume ratio of methanol to formic acid is 1:1. The mixture of floating mud, methanol and formic acid is placed in a 500ml Erlenmeyer flask, and after 5 days of mixing with an air shaker (rotating speed is 180r / min), the floating mud sample is taken and placed in a 100mL graduated cylinder, and the trend of sediment volume over time is recorded. Observe the effect of delaying the compaction of floating mud.

[0029] Control group: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com