Blowing head for forming glass products

A glass product and blowing head technology, applied in the blowing head and other directions, can solve the problems that the pressure of the glass mold is not easy to balance, easy to produce loud noise, and the blowing head cannot accurately control the pressure, etc. pressure, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

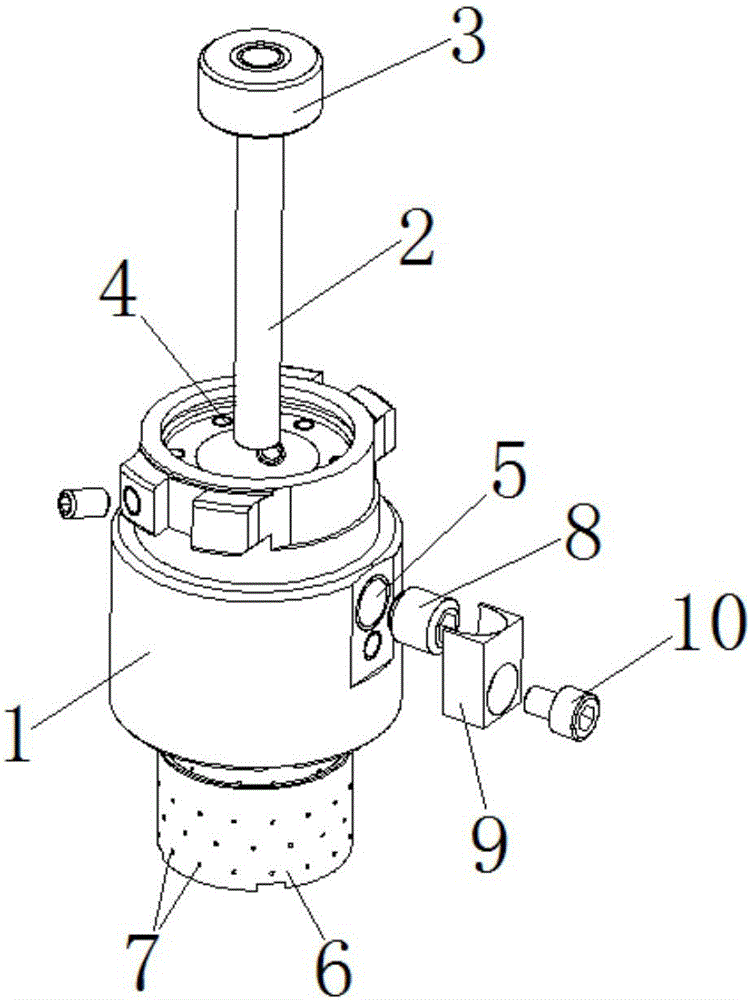

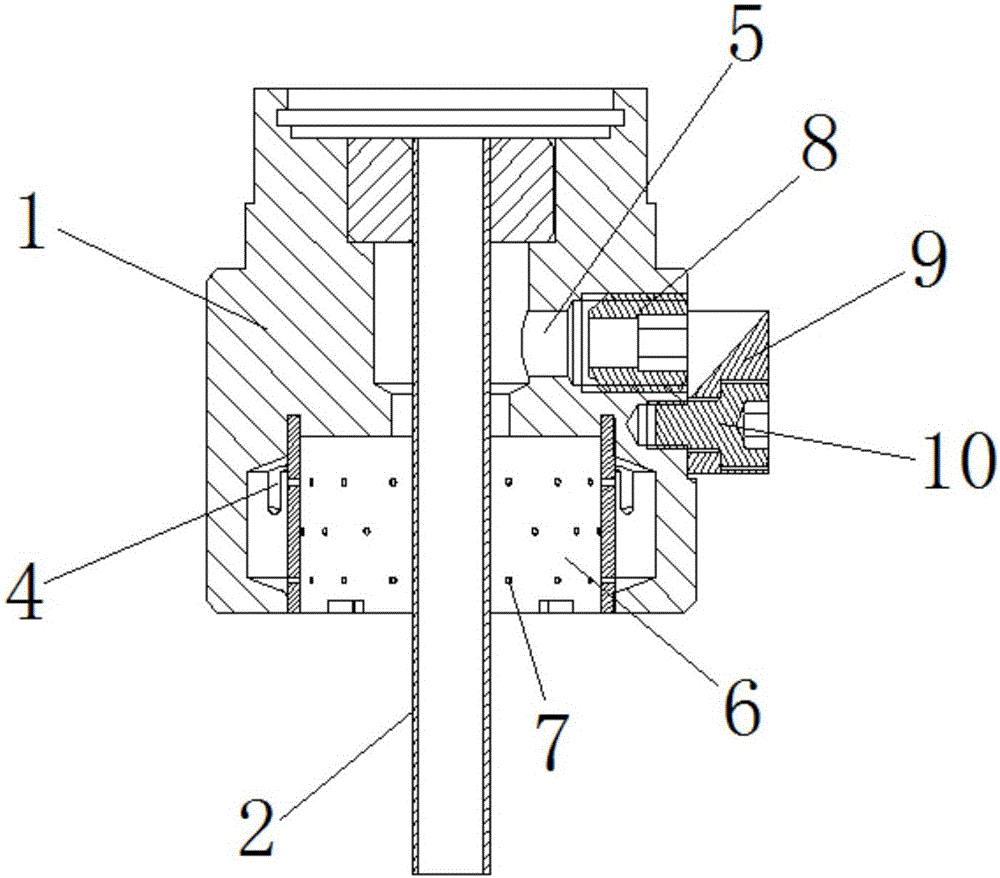

[0013] Such as figure 1 , 2 As shown, an air blowing head for forming glass products includes a nozzle body and an air blowing pipe. There is an air inlet in the nozzle body, and the air blowing pipe is installed in the air inlet. The size of the air inlet is larger than that of the air blowing pipe. , the head end of the blowing pipe is equipped with a blowing head, and the blowing head seals between the blowing pipe and the air inlet, so as to prevent gas from being discharged through the upper air inlet.

[0014] Outside the air inlet, a plurality of vertical balancing air passages are evenly opened on the nozzle body, for example, six are evenly arranged. The lower part of the nozzle body is provided with a circular cavity, and a ventilation groove is provided in the cavity, and the ventilation groove communicates with the balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com