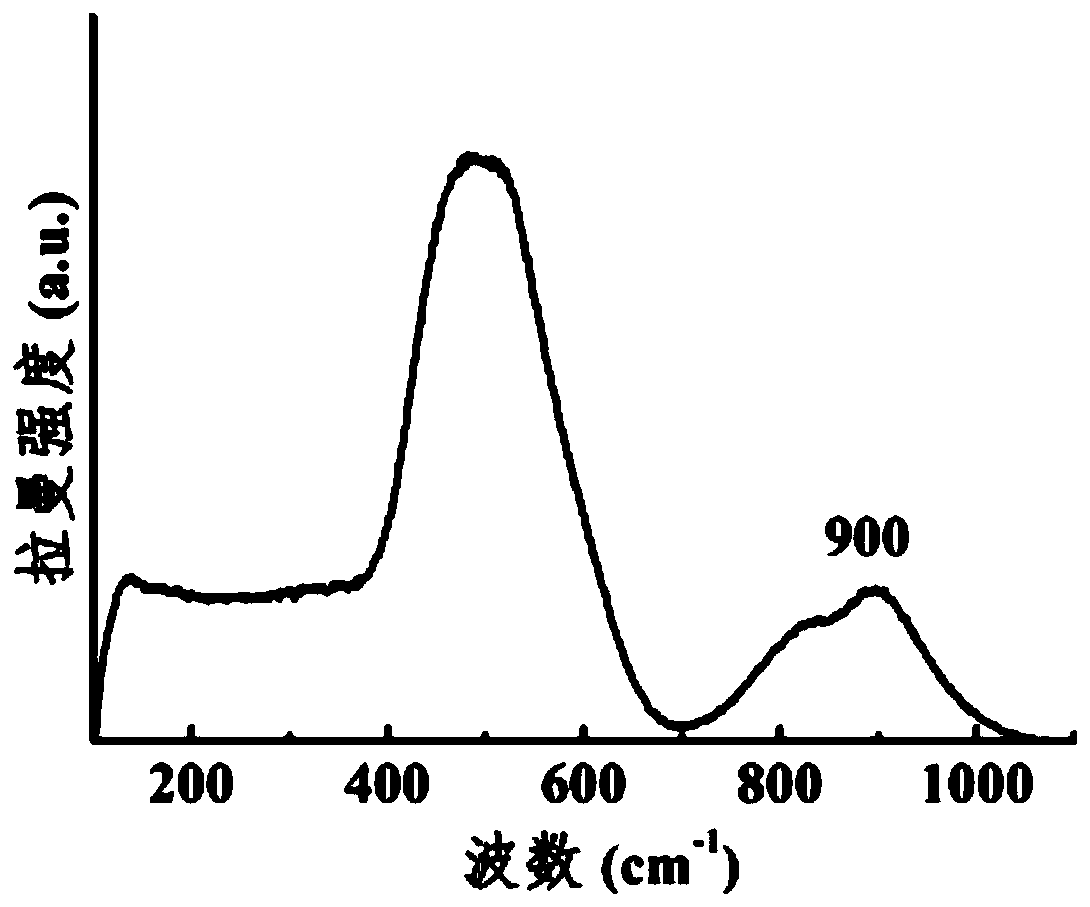

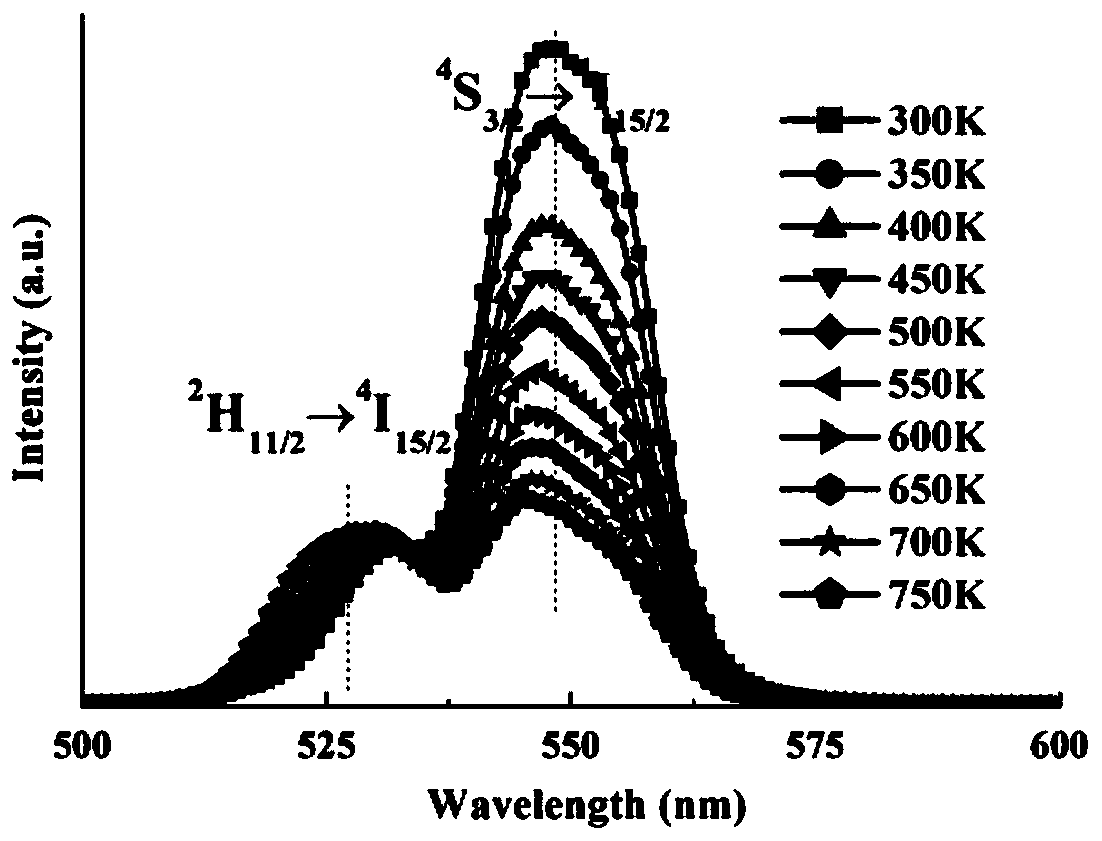

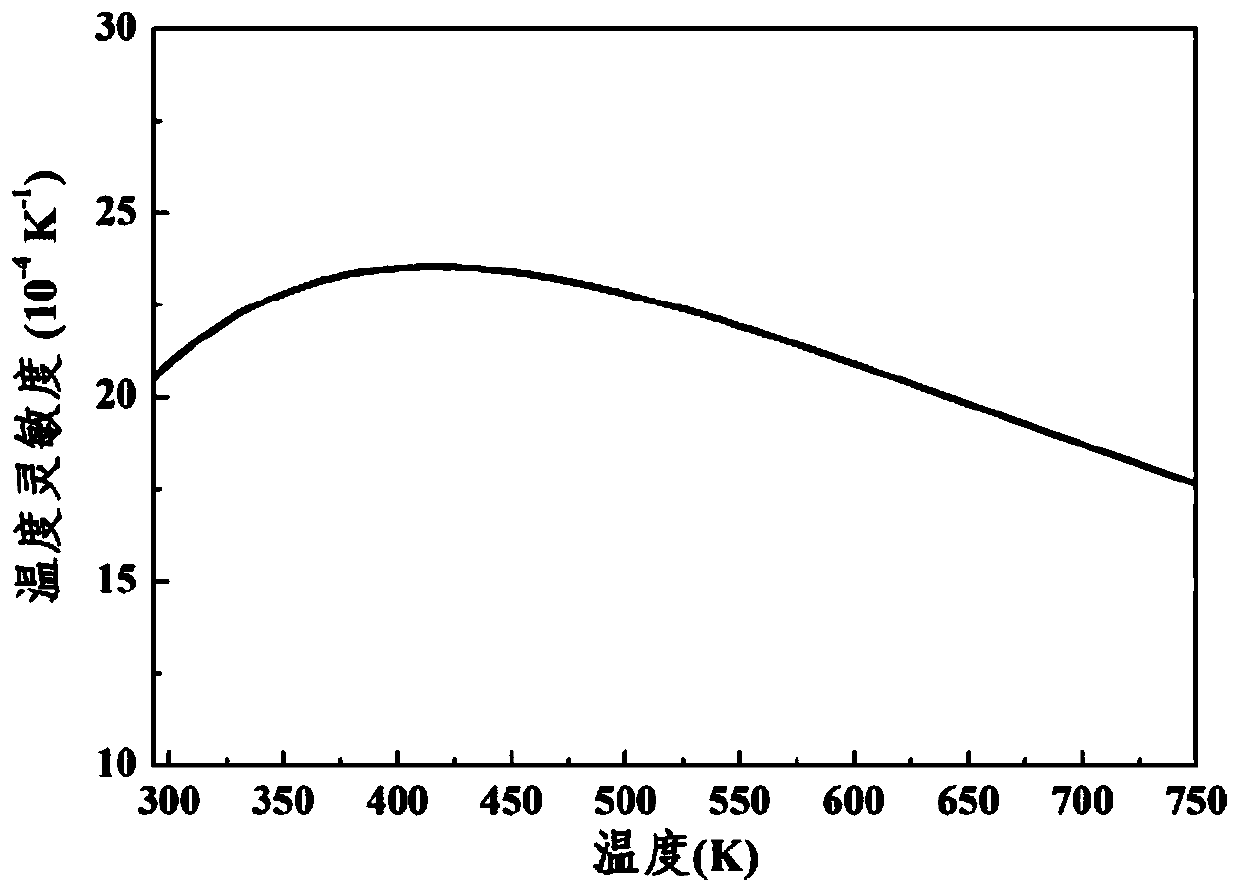

High-temperature optical sensing material Erbium-ytterbium co-doped lead-free fluorogermanate glass and preparation method thereof

A lead-free fluorogermanate and optical sensing technology, which is applied in the field of optical sensing materials and high-temperature optical sensing materials, can solve the problems of low upper limit temperature of thermal sensing, low temperature measurement sensitivity, high phonon energy, etc. , to achieve the effect of improving the luminous efficiency of uploading and switching, good glass performance and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to the formula in Table 1, calculate the weight of the corresponding components, weigh the raw materials and mix them evenly; set the heating rate to 25K / min, put the mixture into the covered platinum crucible and heat up to 1300℃ with the furnace The silicon carbide rods are melted in an electric furnace for 40 minutes to obtain molten glass. During the glass melting process, high-purity oxygen (purity higher than 99.995%) is always introduced for atmosphere protection to remove moisture in the molten glass. After being homogenized and clarified, the glass liquid with moisture removed is quickly poured into a mold that has been preheated to 500°C, and then quickly placed in a muffle furnace that has been heated to 540°C for 2 hours; The rate of the muffle furnace is reduced to 90 ℃, and then the muffle furnace is closed, and the temperature is reduced to room temperature to obtain the annealed erbium-ytterbium co-doped lead-free fluorogermanate glass.

[0046] T...

Embodiment 2

[0050] According to the formula in Table 1, calculate the weight of the corresponding components, weigh the raw materials and mix them evenly; set the heating rate to 25K / min, put the mixture into a covered platinum crucible and heat up to 1400 ℃ with the furnace The silicon carbide rods are melted in an electric furnace for 50 minutes to obtain molten glass. During the glass melting process, high-purity oxygen is always introduced to protect the atmosphere to remove moisture in the molten glass. After being homogenized and clarified, the glass liquid with moisture removed is quickly poured into a mold preheated to 520°C, and then quickly placed in a muffle furnace that has been heated to 550°C, kept for 3 hours, and then heated at 11°C / hour The rate is reduced to 90°C, then the muffle furnace is closed, and the temperature is lowered to room temperature to obtain annealed erbium-ytterbium co-doped lead-free fluorogermanate glass.

Embodiment 3

[0053] According to the formula in Table 1, calculate the weight of the corresponding components, weigh the raw materials and mix them evenly; set the heating rate to 25K / min, put the mixture into a covered platinum crucible and heat up to 1350℃ with the furnace The silicon carbide rods are melted in an electric furnace for 45 minutes to obtain molten glass. During the glass melting process, high-purity oxygen is always introduced to protect the atmosphere to remove moisture in the molten glass. After homogenizing and clarifying the water-removed liquid glass, it is quickly poured into a mold that has been preheated to 510°C, and then quickly placed in a muffle furnace that has been heated to 545°C, kept for 2.5 hours, and then heated at 10°C / hour The rate is reduced to 95°C, then the muffle furnace is turned off, and the temperature is lowered to room temperature to obtain annealed erbium-ytterbium co-doped lead-free fluorogermanate glass.

[0054] The erbium-ytterbium co-doped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com