VCSEL (vertical cavity surface emitting laser) laser tube parameter automatic adjustment method for CPT (coherent population trapping) magnetometer system

An automatic adjustment, laser tube technology, applied to the size/direction of the magnetic field, magnetic field measurement using magneto-optical equipment, etc., can solve the problems of different working temperature and working current, low efficiency, etc., and achieve convenient testing and working parameters The setting, the overall performance is stable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

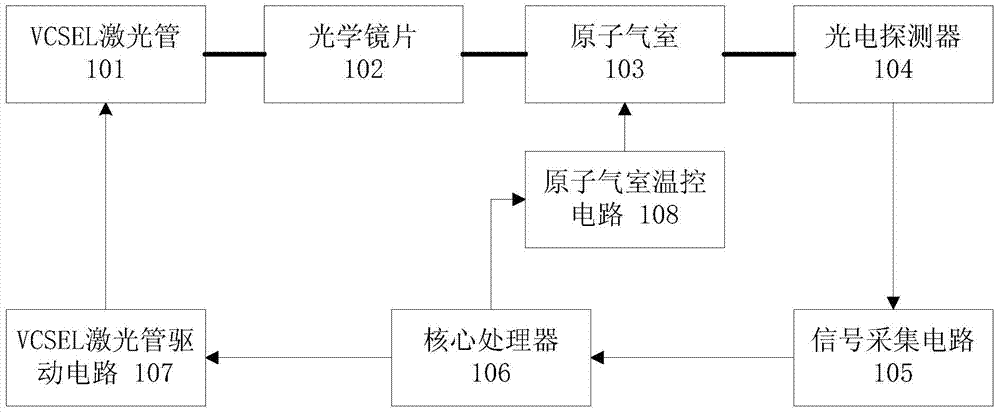

[0022] The structure diagram of the CPT magnetometer system based on the VCSEL laser tube parameter automatic adjustment method proposed by the present invention is as follows: figure 1 As shown, it is composed of a VCSEL laser tube 101, an optical lens 102, an atomic gas cell 103, a photodetector 104, a signal acquisition circuit 105, a core processor 106, a VCSEL laser tube driving circuit 107 and an atomic gas room temperature control circuit 108. The VCSEL laser tube 101, the optical lens 102, the atomic gas cell 103 and the photodetector 104 are located on the same axis.

[0023] The VCSEL laser tube 101 adopts a laser tube with an internal integrated semiconductor thermoelectric cooling regulator (TEC) and a negative temperature coefficient thermistor (NTC), so it is convenient to control the working temperature of the laser tube. TEC is a chip that can freely control heating or cooling. The control terminal is controlled by an external current to control heating or cooling....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com