Processing method of waste tobacco

A processing method and technology of waste tobacco leaves, applied in the field of tobacco processing, can solve the problem of low extraction efficiency of active ingredients, achieve the effects of rich active ingredients, increased pleasure, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

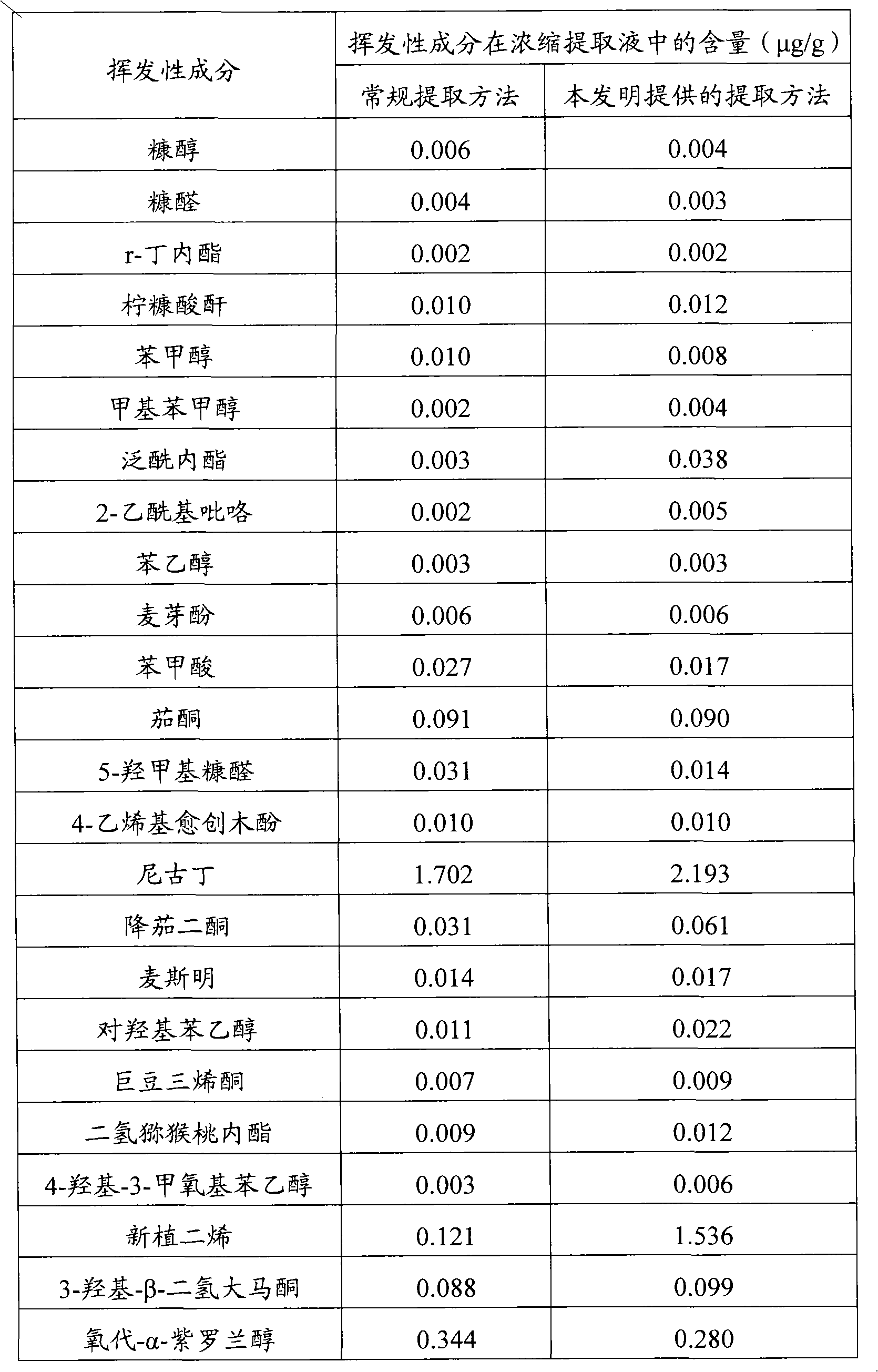

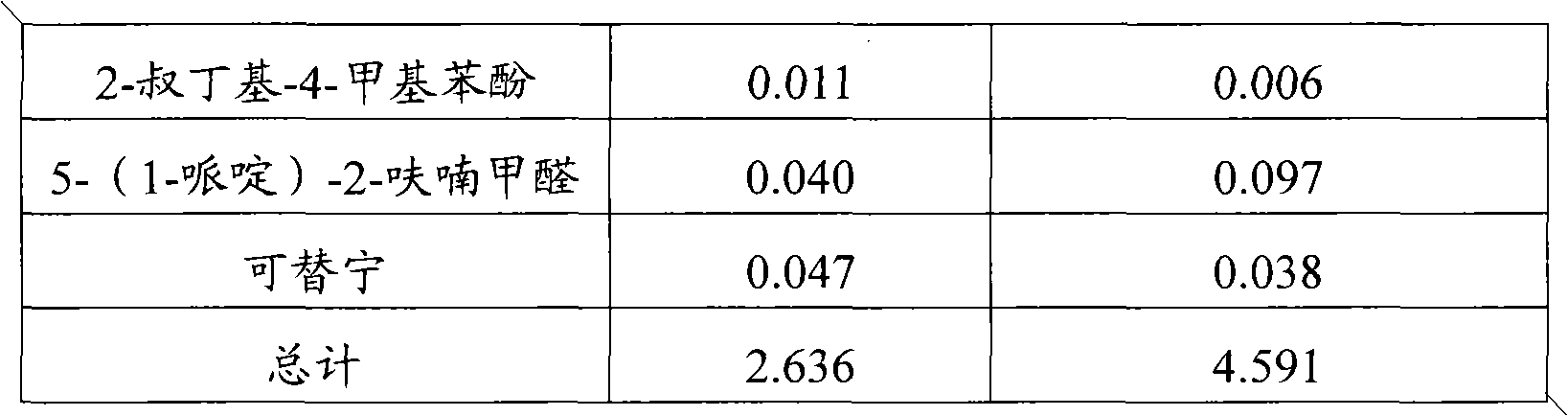

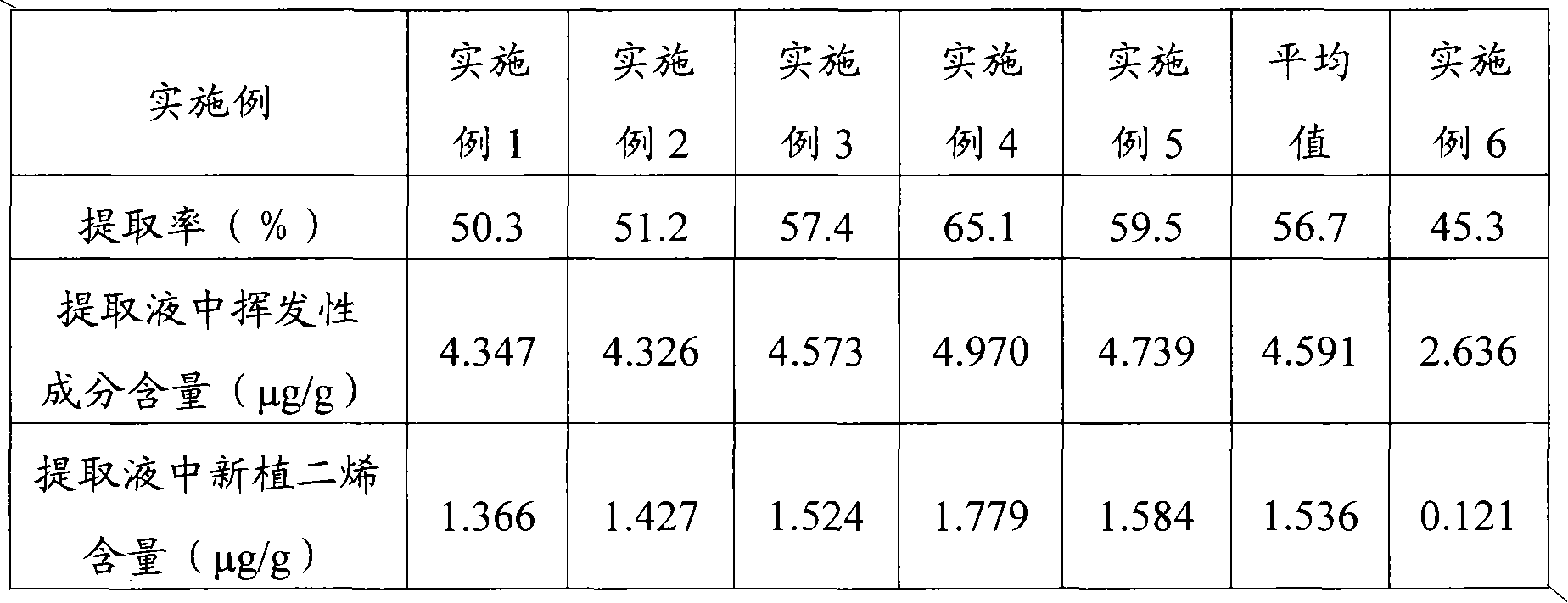

Examples

Embodiment 1

[0029] Embodiment 1: the processing method of the present invention handles waste inferior tobacco leaves

[0030] The raw material waste tobacco leaves were hand-cut into shreds, dried in an oven at 40°C for 5 hours, crushed, left overnight, and stored in sealed bags for later use.

[0031] Take 30g of shredded tobacco leaves and place in a 500mL conical flask, add 300mL of citric acid-sodium citrate buffer solution with a pH value of 5.4. Then add 0.04g compound plant hydrolase, 0.08g cellulase, and 0.04g neutral protease. The above three enzymes were all purchased from Novozymes (China) Biotechnology Co., Ltd. 45°C air-bath shaker shake reaction for 5h, filter, add 100mL of water, shake and extract at room temperature for 20min, combine the extracts, and concentrate to 25mL by rotary evaporation under reduced pressure to obtain a concentrated extract.

Embodiment 2

[0032] Embodiment 2: processing method of the present invention handles waste inferior tobacco leaf

[0033] The raw material waste tobacco leaves were hand-cut into shreds, dried in an oven at 40°C for 5 hours, crushed, left overnight, and stored in sealed bags for later use.

[0034] Take 40g of shredded tobacco leaves and place in a 500mL conical flask, add 200mL of disodium hydrogen phosphate-potassium dihydrogen phosphate buffer solution with a pH value of 4.6. Then add 0.02 g of compound plant hydrolase Viscozyme L, 0.04 g of cellulase (fungal cellulase), and 0.02 g of neutral protease. The above three enzymes were all purchased from Novozymes (China) Biotechnology Co., Ltd. 50°C air-bath shaker shake reaction for 7h, filter, add 80mL of water, shake and extract at room temperature for 40min, combine the extracts, and concentrate to 25mL by rotary evaporation under reduced pressure to obtain a concentrated extract.

Embodiment 3

[0035] Embodiment 3: processing method of the present invention handles waste inferior tobacco leaf

[0036] The raw material waste tobacco leaves were hand-cut into shreds, dried in an oven at 40°C for 5 hours, crushed, left overnight, and stored in sealed bags for later use.

[0037] Take 20g of shredded tobacco leaves and place in a 500mL conical flask, add 160mL of acetic acid-sodium acetate buffer solution with a pH value of 4.8. Then add 0.04g compound plant hydrolytic enzyme, 0.08g cellulase, 0.04g neutral protease, 30°C air bath shaker shake reaction for 8h, filter, add 60mL water, shake and extract at room temperature for 60min, combine the extracts, and rotary evaporate under reduced pressure Concentrate to 25 mL to obtain a concentrated extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com