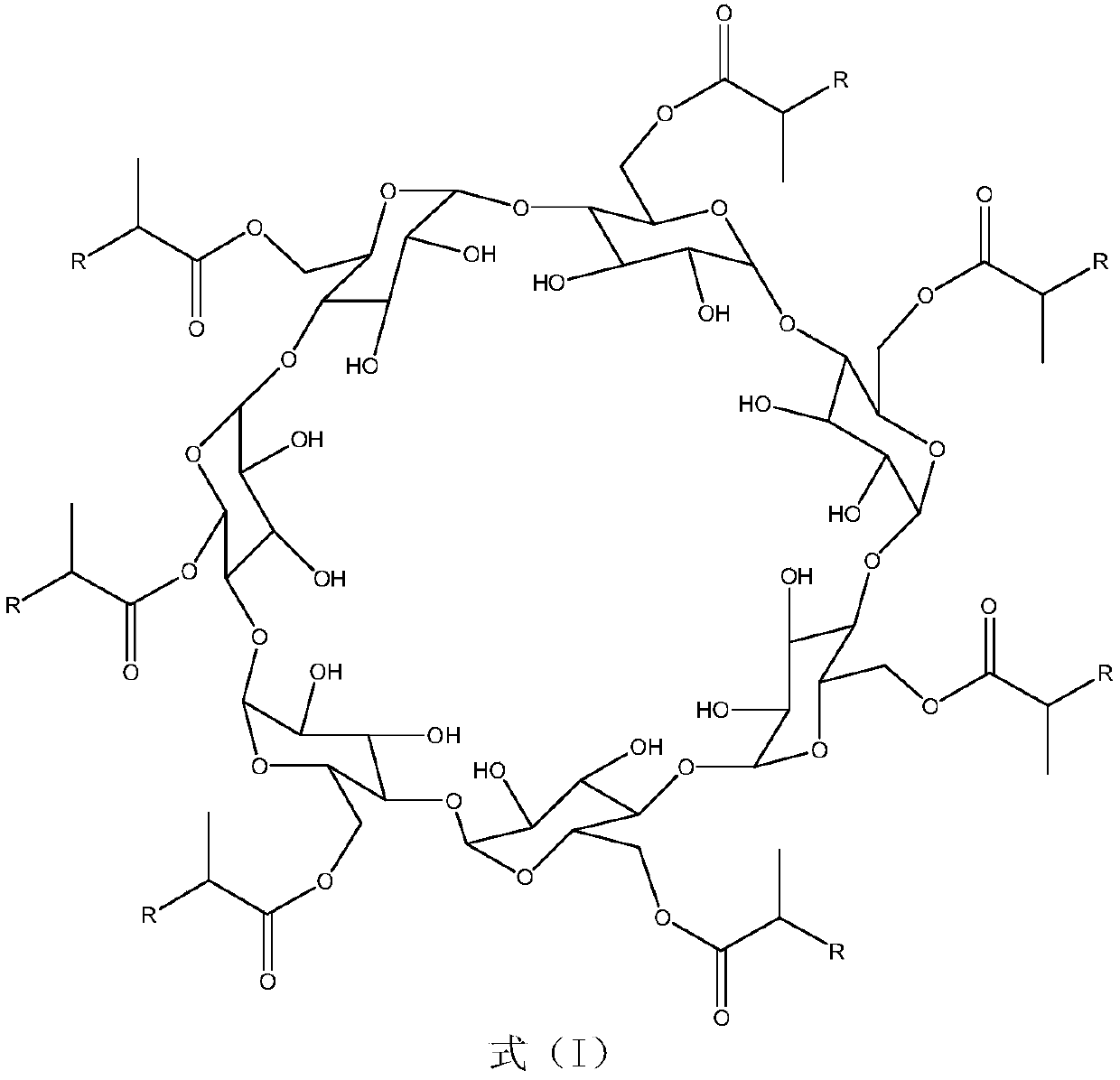

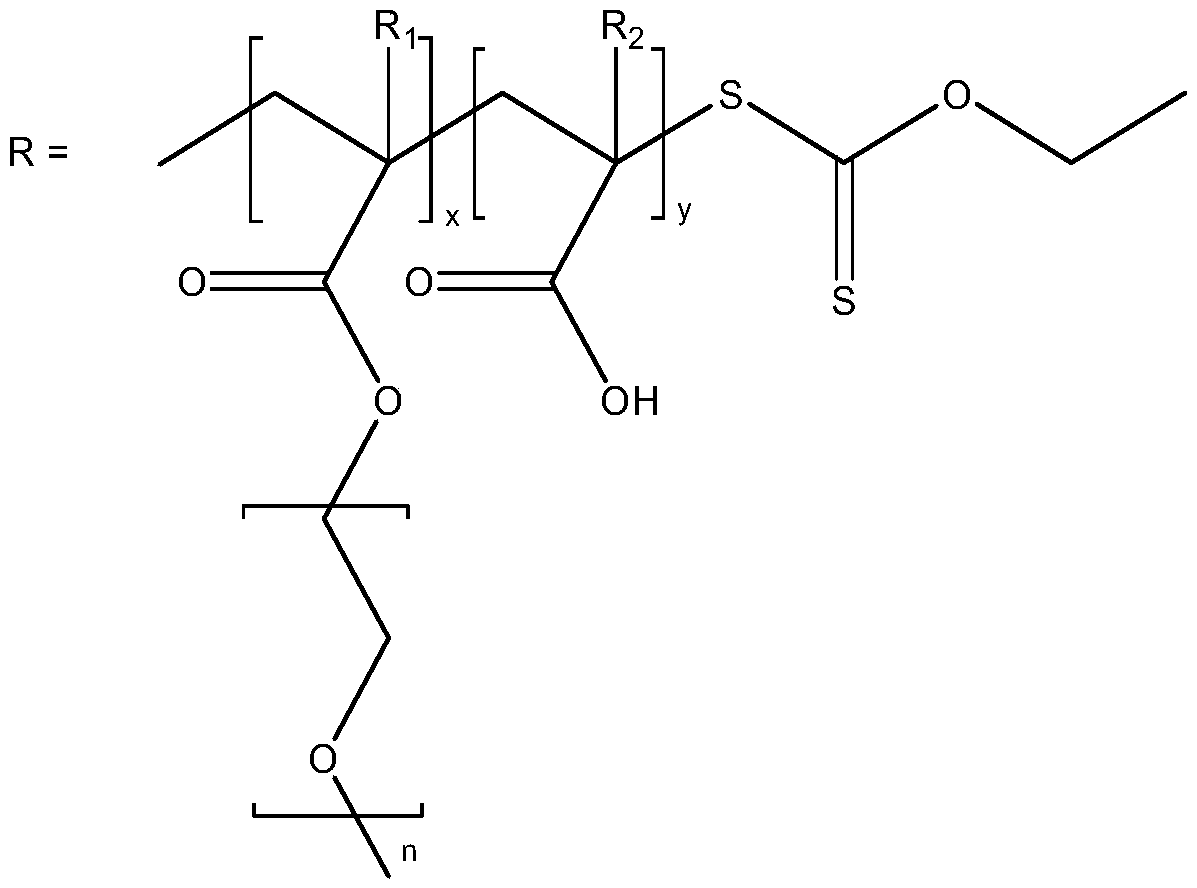

A star-shaped block polycarboxylate water reducer and its preparation method

A technology of water reducing agent and polycarboxylic acid, applied in the field of water reducing agent and its preparation, star-shaped block polycarboxylate water reducing agent and its preparation field, to achieve the advantages of controllable molecular weight, high water reducing rate and increasing adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of Star Chain Initiator

[0030] Potassium O-ethylxanthate (16.03 g, 0.1 mol) was dissolved in 80 mL of anhydrous tetrahydrofuran (THF), added to a 150 mL three-neck flask, and then triethylamine (10.1, 0.1 mol) was added as a proton absorber. Stir in an ice-water bath for 0.5 h under nitrogen atmosphere. 2-Bromopropionyl bromide (26.1 g, 0.1 mol) was dissolved in 20 mL of anhydrous THF, then added to a constant pressure dropping funnel, and added drop by drop into a three-necked flask. After the dropwise addition was completed, the reaction was carried out at room temperature for 24 h under nitrogen atmosphere. After the reaction is finished, the reaction solution is filtered, and the filtrate is rotary evaporated to remove the solvent to obtain a dithioester compound containing an acid bromide group.

[0031] β-cyclodextrin (11.35g, 0.01mol) was dissolved in 60mL of anhydrous N,N-dimethylformamide (DMF), added to a 100mL three-necked flask, and then ...

Embodiment 2

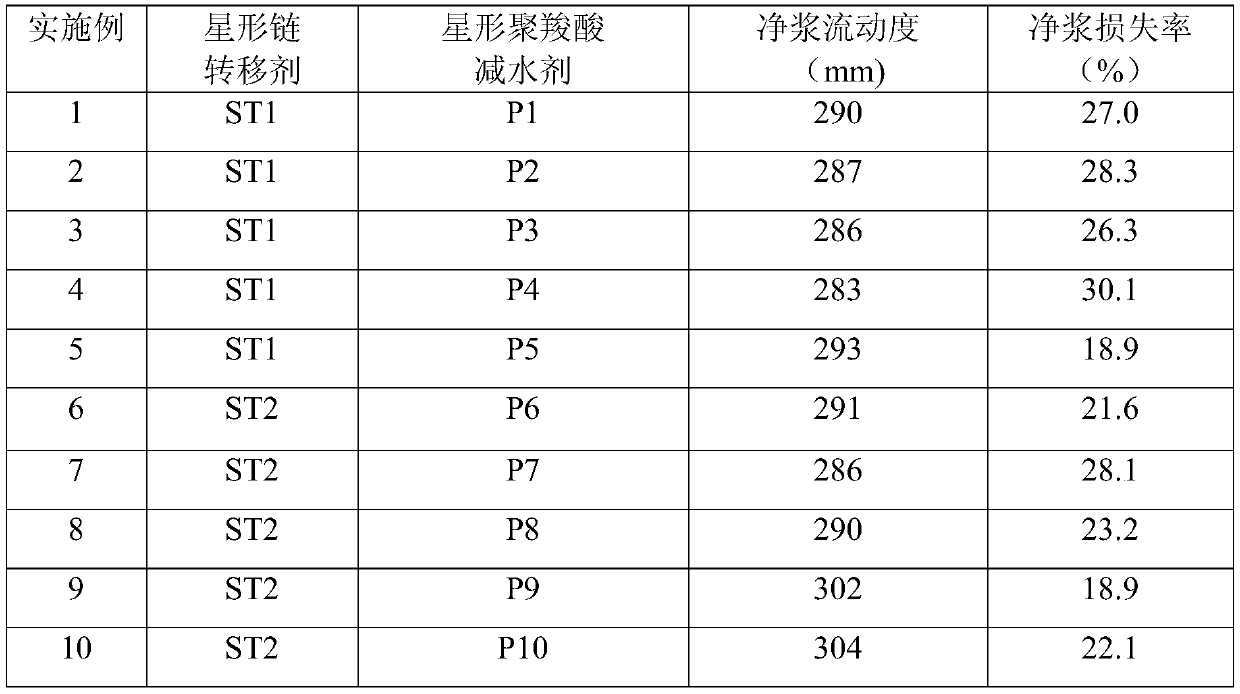

[0039] In this example, a star-shaped block polycarboxylate water reducer (marked as SP2) was prepared in the same manner as in Example 1, except that the molecular weight of polyethylene glycol methacrylate in step (2) was 1000 g / mol.

[0040] In this embodiment, the slurry fluidity and soil resistance performance are tested in the same manner as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0042] In this example, a star-shaped block polycarboxylate water reducer (marked as SP3) was prepared in the same manner as in Example 1, except that the molecular weight of polyethylene glycol methacrylate in step (2) was 500 g / mol.

[0043] In this embodiment, the slurry fluidity and soil resistance performance are tested in the same manner as in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com