Aromatic polyester polyol with good compatibility with cyclopentane and preparation method thereof

A technology of aromatic polyester and aromatic dibasic acid, which is applied in the field of aromatic polyester polyol and its preparation, can solve the problems of poor compatibility between aromatic polyester polyol and pentane, and achieves high yield, The effect of simple reaction operation and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

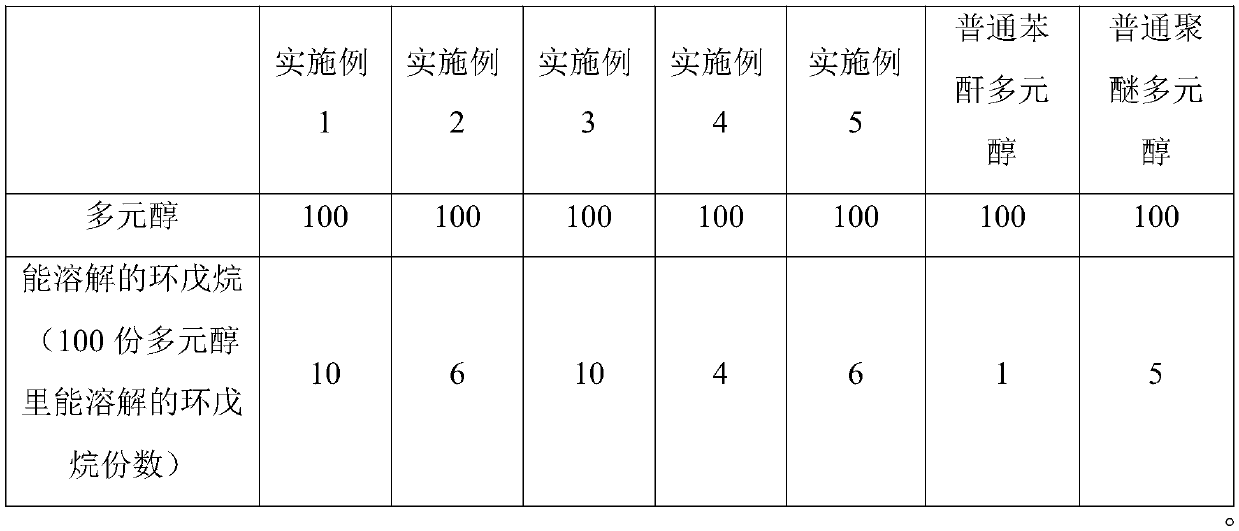

Examples

Embodiment 1

[0022] In a 1000ml reaction flask equipped with a stirrer, nitrogen protection and condensing reflux device, add 371.98g, 2.51mol of phthalic anhydride and 41.72g, 0.25mol of terephthalic acid, 406.56g, 4.52mol of 1,3 -Butanediol, 79.73g, 0.59mol of trimethylolpropane, start stirring, slowly heat up to 180-190°C, turn on nitrogen, after 60 minutes of reaction, heat up to 220-230°C, carry out esterification dehydration reaction, 220- After holding at 230°C for 120 minutes, carry out polycondensation reaction by vacuum distillation, and check the acid value and hydroxyl value every 60 minutes. After the acid value and hydroxyl value are qualified, the temperature is lowered to below 100°C, and the material is packaged.

[0023] The hydroxyl value of the synthetic polyester polyol of the present embodiment is 310mgKOH / g, and the acid value is 3.1mgKOH / g;

[0024] The number average molecular weight of the synthetic polyester polyol of the present embodiment is 430;

[0025] The ...

Embodiment 2

[0027] In a 1000ml reaction flask equipped with a stirrer, nitrogen protection and condensing reflux device, add 348.86g, 2.36mol of phthalic anhydride and 65.22g, 0.39mol of terephthalic acid, 426.44g, 4.74mol of 1,3 -Butanediol, 59.48g, 0.44mol of trimethylolpropane, start stirring, slowly heat up to 180-190°C, turn on nitrogen, after 60 minutes of reaction, heat up to 220-230°C, carry out esterification dehydration reaction, 220- After holding at 230°C for 120 minutes, carry out polycondensation reaction by vacuum distillation, and check the acid value and hydroxyl value every 60 minutes. After the acid value and hydroxyl value are qualified, the temperature is lowered to below 100°C, and the material is packaged.

[0028] The hydroxyl value of the polyester polyol synthesized by the present embodiment is 310mgKOH / g, and the acid value is 3.4mgKOH / g;

[0029] The number average molecular weight of the polyester polyol synthesized by the present embodiment is 416;

[0030] ...

Embodiment 3

[0032] In a 1000ml reaction flask equipped with a stirrer, nitrogen protection and condensing reflux device, add 349.54g, 2.36mol of phthalic anhydride and 49.0g, 0.29mol of terephthalic acid, 388.53g, 4.32mol of 1,3 -Butanediol, 112.91g, 0.84mol of trimethylolpropane, start stirring, slowly heat up to 180-190°C, turn on nitrogen, after 60 minutes of reaction, heat up to 220-230°C, carry out esterification dehydration reaction, 220- After holding at 230°C for 120 minutes, carry out polycondensation reaction by vacuum distillation, and check the acid value and hydroxyl value every 60 minutes. After the acid value and hydroxyl value are qualified, the temperature is lowered to below 100°C, and the material is packaged.

[0033] The hydroxyl value of the polyester polyol synthesized by the present embodiment is 350mgKOH / g, and the acid value is 2.5mgKOH / g;

[0034] The number average molecular weight of the synthetic polyester polyol of present embodiment is 400;

[0035] The yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com