Method for preparing liquorice root extract for tobaccos

A technology for licorice extract and tobacco, which is applied in the preparation of tobacco, tobacco, and tobacco treatment, etc. It can solve the problems of low yield of total extract from licorice raw materials, insufficient extraction of aroma components, and inability to fully utilize raw materials, etc., to achieve Short extraction time, improved aroma and product quality, and increased extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

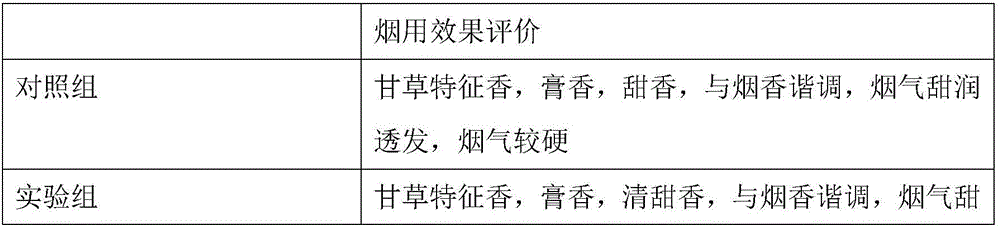

Embodiment 1

[0030] 1) Weigh 400g of licorice slices (1cm), put them into a pressure vessel, raise the pressure to 8MPa at 25°C, keep it for 8 minutes, release the pressure to normal pressure instantly, so that the licorice slices are fluffy, and set aside;

[0031] 2) Weigh 200g of expanded licorice tablets in step 1) and put them into supercritical CO 2 In the extractor, add 6g of absolute ethanol, set the CO 2 The flow rate is 1Kg / h, the extraction pressure is 25MPa, the extraction time is 2h, and the extraction temperature is 50°C, and a clear and transparent liquid is obtained, which is the licorice extract.

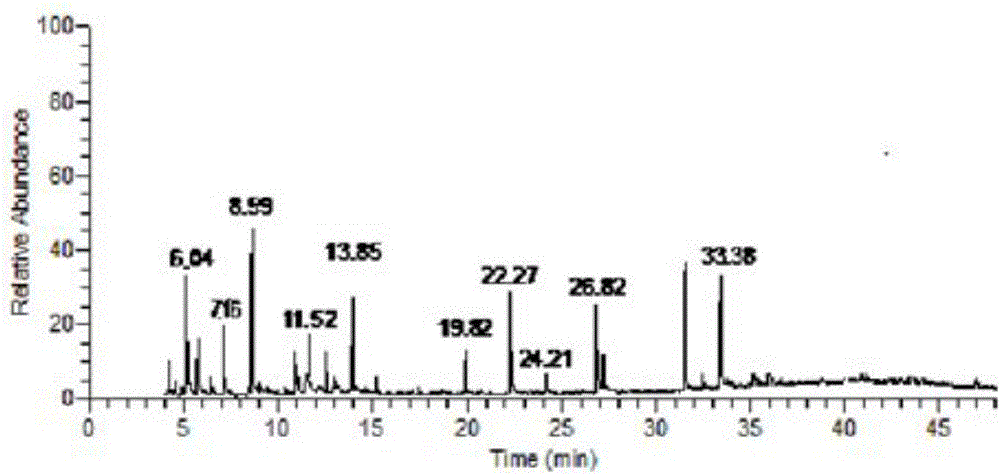

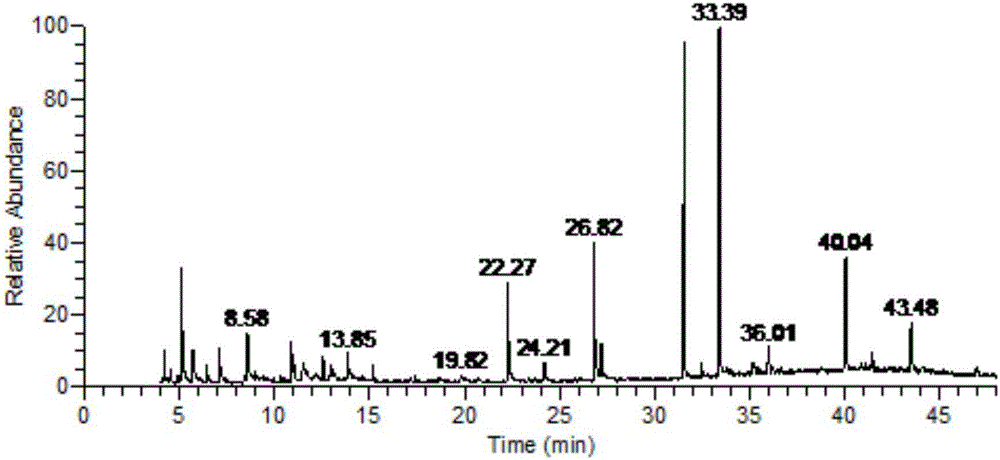

[0032] 3) Put the preliminary prepared licorice extract into the evaporating flask of the molecular distillation equipment, and control the preheating temperature to 35°C, the evaporation temperature to 48°C, the cooling temperature to -10°C, the frequency of the peristaltic pump to 35Hz, and the speed of the wiper to be 150rpm, evaporating pressure is 5mbar, collects licorice ...

Embodiment 2

[0035] 1) Weigh 300g of licorice slices (0.8cm), put them into a pressure vessel, raise the pressure to 7MPa at 28°C, keep it for 10 minutes, release the pressure to normal pressure instantly, so that the licorice slices are fluffy, and set aside ;

[0036] 2) Weigh 240g of expanded licorice tablets in step 1) and put them into supercritical CO 2 In the extractor, add 7g of absolute ethanol, set the CO 2 The flow rate is 2Kg / h, the extraction pressure is 30MPa, the extraction time is 2h, and the extraction temperature is 40°C. The clear and transparent liquid obtained is the licorice extract.

[0037] 3) Put the preliminary prepared licorice extract into the evaporating flask of the molecular distillation equipment, and control the preheating temperature to 38°C, the evaporation temperature to 50°C, the cooling temperature to -7°C, the frequency of the peristaltic pump to 30Hz, and the speed of the wiper to be 120rpm, the evaporating pressure is 6mbar, collect the light frac...

Embodiment 3

[0040] 1) Weigh 300g of licorice slices (0.8cm), put them into a pressure vessel, raise the pressure to 6MPa at 28°C, keep it for 12 minutes, release the pressure to normal pressure instantly, so that the licorice slices are fluffy, and set aside ;

[0041] 2) Weigh 200g of expanded licorice tablets in step 1) and put them into supercritical CO 2 In the extractor, add 10g ethyl acetate, set CO 2 The flow rate is 3Kg / h, the extraction pressure is 40MPa, the extraction time is 1.5h, and the extraction temperature is 50°C. The clear and transparent liquid obtained is the licorice extract.

[0042]3) Put the preliminary prepared licorice extract into the evaporating flask of the molecular distillation equipment, and control the preheating temperature to 30°C, the evaporation temperature to 45°C, the cooling temperature to -15°C, the frequency of the peristaltic pump to 30Hz, and the speed of the wiper to be 200rpm, the evaporation pressure is 7mbar, collect the light fraction 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com