A method for compound microbial fermentation to improve the quality of tobacco flakes

A technology of composite microorganisms and composite microorganisms, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of single aroma, insufficient aroma, and no natural rich aroma, etc., to improve the quality of thin slices, aroma Naturally enriched, irritation-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

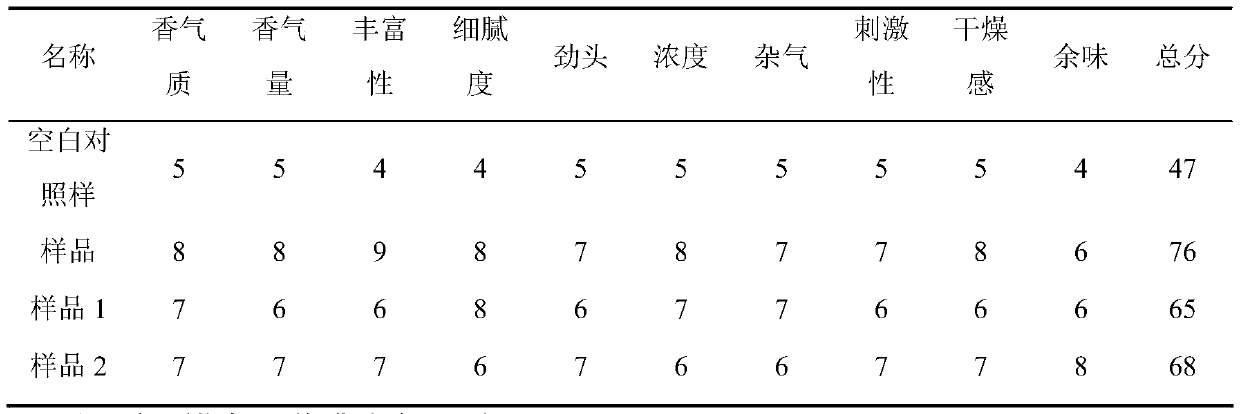

Embodiment 1

[0023] Place the lactic acid bacteria and golden flower strains at a temperature of 20°C for 4 hours, then inoculate the lactic acid bacteria and golden flower strains on the activated medium according to the inoculation amount of 1% of the weight of the medium, and cultivate them at 20°C. For 48 hours, the bacterial seeds were prepared; the lactic acid bacteria and the golden flower bacteria were mixed according to a certain ratio, so that the number of live bacteria of the lactic acid bacteria was 5×10 7 cFu / ml, the number of live bacteria of Jinhua bacteria is 4×10 7 cFu / ml.

[0024] Take 1Kg of tobacco flakes and put them into the warehouse of aged tobacco leaves, evenly disperse the tobacco flakes, and evenly spray the compound microbial bacterial liquid of lactic acid bacteria and golden flower bacteria on the surface of the tobacco flakes. The amount of bacterial liquid applied is 1% of the weight of the tobacco flakes % fermented for 5 days, and the temperature was co...

Embodiment 2

[0035] Place the lactic acid bacteria and golden flower strains at a temperature of 30°C for 2 hours, then inoculate the lactic acid bacteria and golden flower strains on the activated medium according to the inoculation amount of 3% of the weight of the medium, and cultivate them at 30°C. After 24 hours, the bacteria seeds were prepared; the lactic acid bacteria and the golden flower bacteria were mixed according to a certain ratio, so that the number of live bacteria of the lactic acid bacteria was 1×10 7 cFu / ml, the number of live bacteria of Jinhua bacteria is 1×10 7 cFu / ml.

[0036] Take 1Kg of tobacco flakes and put them into the warehouse of aged tobacco leaves, evenly disperse the tobacco flakes, and evenly spray the compound microbial bacterial liquid of lactic acid bacteria and golden flower bacteria on the surface of the tobacco flakes. % Fermented for 9 days, the temperature was controlled at 32°C.

[0037] Finally, the tobacco sheets are naturally stored at room...

Embodiment 3

[0046]Place the lactic acid bacteria and golden flower strains at a temperature of 35°C for 3 hours, then inoculate the lactic acid bacteria and golden flower strains on the activated medium according to the inoculation amount of 5% of the weight of the medium, and cultivate them at 25°C. For 48 hours, the bacterial seeds were prepared; the lactic acid bacteria and the golden flower bacteria were mixed according to a certain ratio, so that the number of live bacteria of the lactic acid bacteria was 3×10 8 cFu / ml, the number of live bacteria of Jinhua bacteria is 5×10 8 cFu / ml.

[0047] Take 1Kg of tobacco flakes and put them into the warehouse of aged tobacco leaves, spread the tobacco flakes evenly, and evenly spray the composite microbial bacterial liquid of lactic acid bacteria and golden flower bacteria on the surface of the tobacco flakes, the amount of bacterial liquid applied is 5% of the weight of the tobacco flakes %, fermented for 6 days, and the temperature was con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com