A kind of preparation method of high-performance beryllium aluminum-rare earth alloy and its prepared product

A rare earth alloy and rare earth intermediate alloy technology, applied in the field of alloy preparation and beryllium aluminum alloy, can solve the problems of difficult to produce complex structural parts, alloy composition segregation, complex process, etc. high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

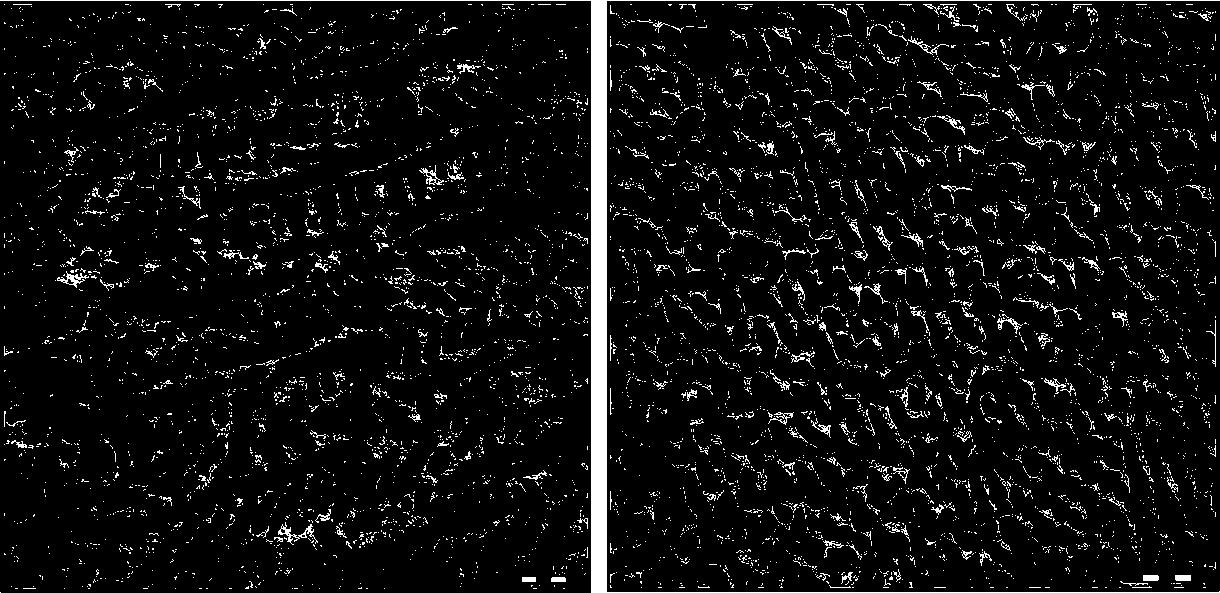

Image

Examples

preparation example Construction

[0047] The invention provides a method for preparing a novel high-performance beryllium-aluminum-rare earth alloy and the product thereof, wherein the alloy is composed of the following raw materials in mass percentage: beryllium content is 45-80%, aluminum content is 10-45%, rare earth The element content is 0.1~10%, and the rest are all impurities. Among them, rare earth elements include lanthanum (La), cerium (Ce), praseodymium (Pr), samarium (Sm), europium (Eu), gadolinium (Gd), erbium (Er), yttrium (Y), scandium (Sc), One or more of ytterbium (Yb), neodymium (Nd), and lutetium (Lu).

[0048] The specific steps of the method are as follows.

[0049] (1) Weigh each component according to the proportion and set aside. Put the rare earth element and some metal aluminum (calculated amount) into the mold in the vacuum induction melting furnace for melting, and cast to obtain the aluminum-rare earth master alloy ingot. Among them, the mass percentage of rare earth elements in...

Embodiment 1

[0061] In this embodiment, each component is weighed according to mass percentage: the beryllium content is 62%, the aluminum content is 37%, the rare earth element lanthanum content is 0.4%, the rare earth element erbium content is 0.4%, and the remaining 0.2% is all impurities.

[0062] The specific steps of this embodiment are as follows.

[0063] (1) Weigh each component according to the proportion and set aside. Calculate and prepare metal aluminum and rare earth lanthanum and erbium metal ingot raw materials, and design the total mass percentage of rare earth elements lanthanum and erbium in the aluminum-rare earth master alloy to be 30%. Considering that the volatility of metal aluminum is higher than that of lanthanum and erbium at higher melting temperature and higher vacuum degree, therefore, the amount of aluminum input is increased by 1.68% on the basis of the original calculation result.

[0064] Put the rare earth lanthanum and erbium metal ingot raw materials w...

Embodiment 2

[0071] In this embodiment, each component is weighed according to mass percentage: the beryllium content is 70%, the aluminum content is 28%, the rare earth element scandium content is 1.0%, the rare earth element cerium content is 0.8%, and the remaining 0.2% is the total content of all impurities.

[0072] The specific steps of this embodiment are as follows.

[0073] (1) Preparation of aluminum-scandium-cerium master alloy

[0074] Weigh each component according to the proportion and set aside. Calculate and prepare metal aluminum and rare earth scandium and cerium metal particle raw materials, and design the total mass percentage of rare earth elements scandium and cerium in the aluminum-rare earth master alloy to be 35%. Considering that the volatility of metal aluminum is higher than that of scandium and cerium at higher melting temperature and higher vacuum degree, the amount of aluminum input is increased by 1.82% based on the original calculation results. Due to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com