Spring steel with performance of low decarburization, high strength and high ductility

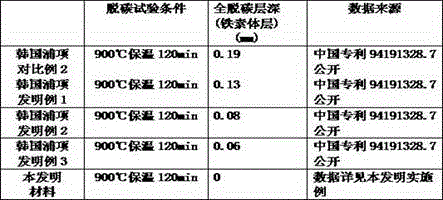

A high-strength, high-plasticity technology, applied in the field of spring steel, can solve the problems of severe decarburization, increased decarburization tendency of steel, difficulty in meeting low decarburization, high-strength, high-plasticity and low-cost, etc. The effect of crystallizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

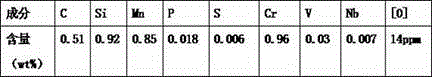

[0048] A kind of spring steel with low decarburization, high strength and high plasticity described in the present invention comprises the following components according to the percentage by mass:

[0049] C 0.42-0.52%;

[0050] Si 0.7-1.1%;

[0051] Mn 0.5-1.10%;

[0052] Cr 0.5-1.10%;

[0053] V 0.01-0.05%;

[0054] Nb 0.005-0.009%;

[0055] Among them, P≤0.025%, S≤0.025%, [O]5-25ppm;

[0056] The balance is Fe and unavoidable impurities.

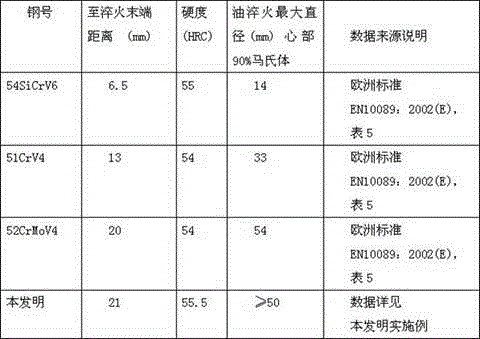

[0057] Specific examples are shown in Table 5.

[0058] table 5

[0059]

[0060] The balance is Fe and unavoidable impurities.

[0061] The metallurgical production process of the spring steel material of the present invention is: according to the above 1) material composition (Wt%) batching, industrial production electric furnace smelting, furnace outer ladle refining and degassing treatment, mold casting, billet opening, pickling, repairing Grinding, rolling. Hot rolled material: 28x90mm flat steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com