A high-strength spring steel

A spring steel, high-strength technology, used in springs, low-internal friction springs, springs/shock absorbers, etc., can solve the problem of low fatigue performance, unsatisfactory high strength and high plastic toughness, few pieces of variable-section leaf springs and low breakout. Carbon and other problems, to achieve the effect of reducing alloying element content, reducing material cost and improving material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

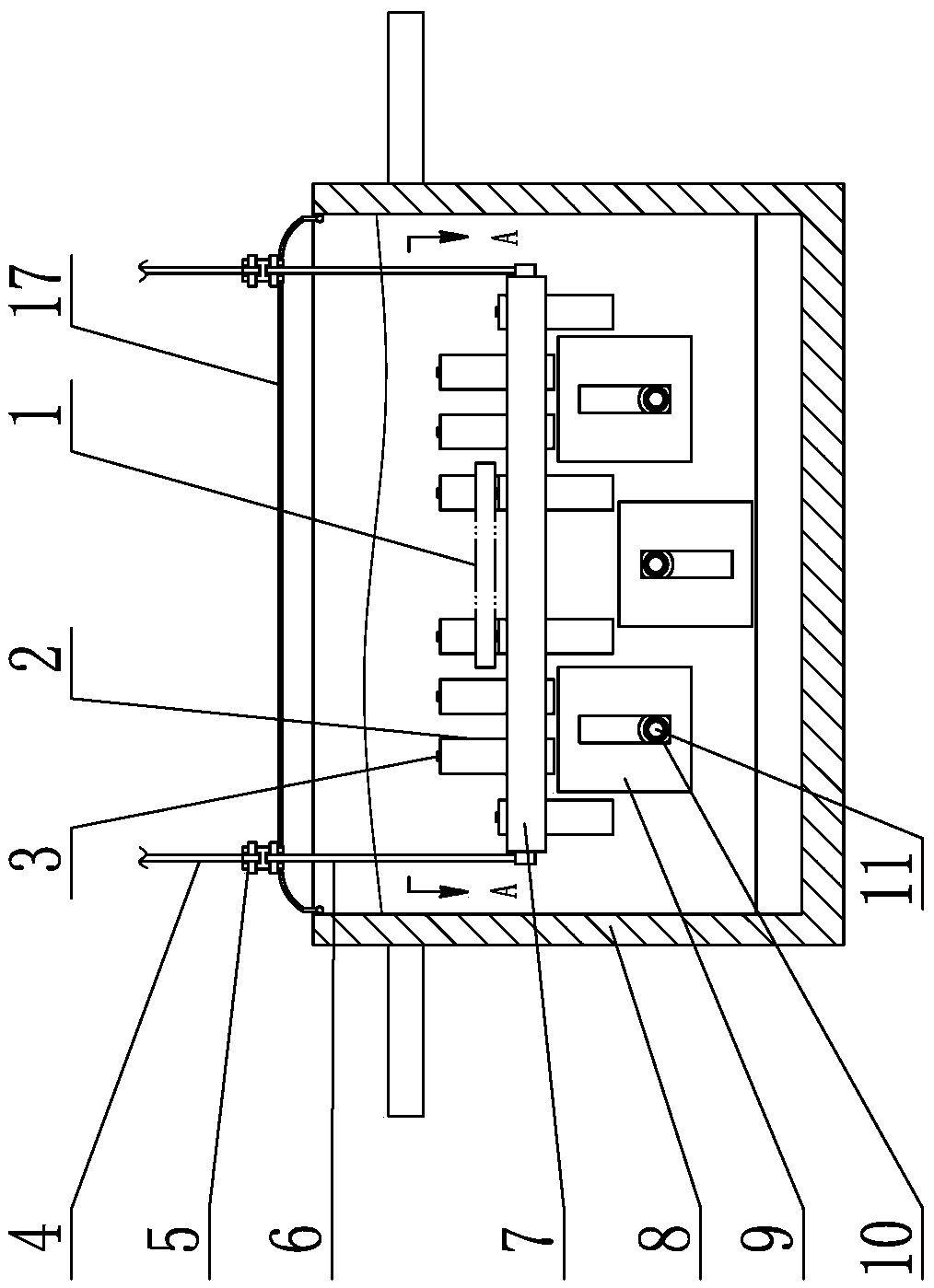

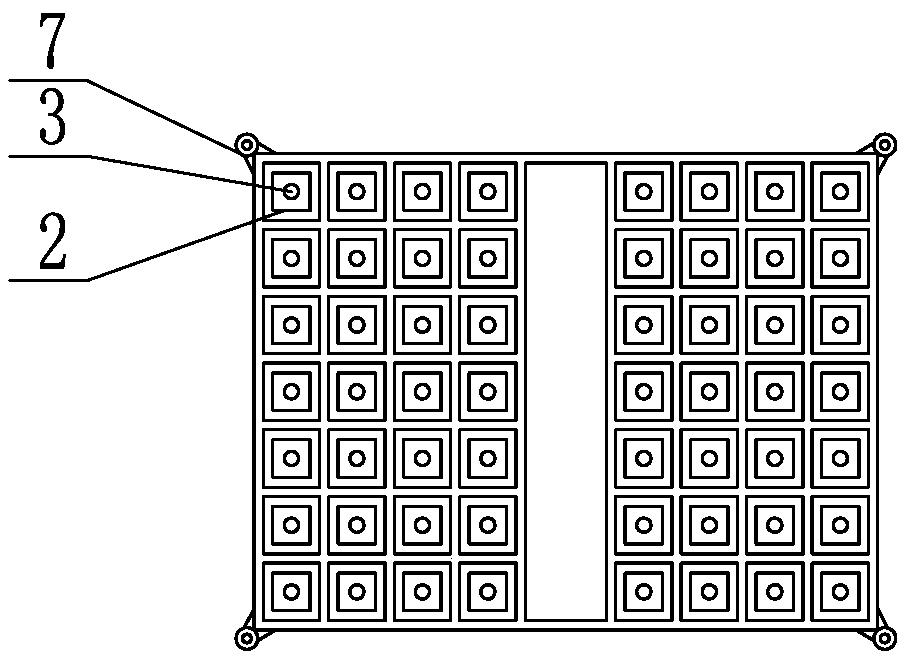

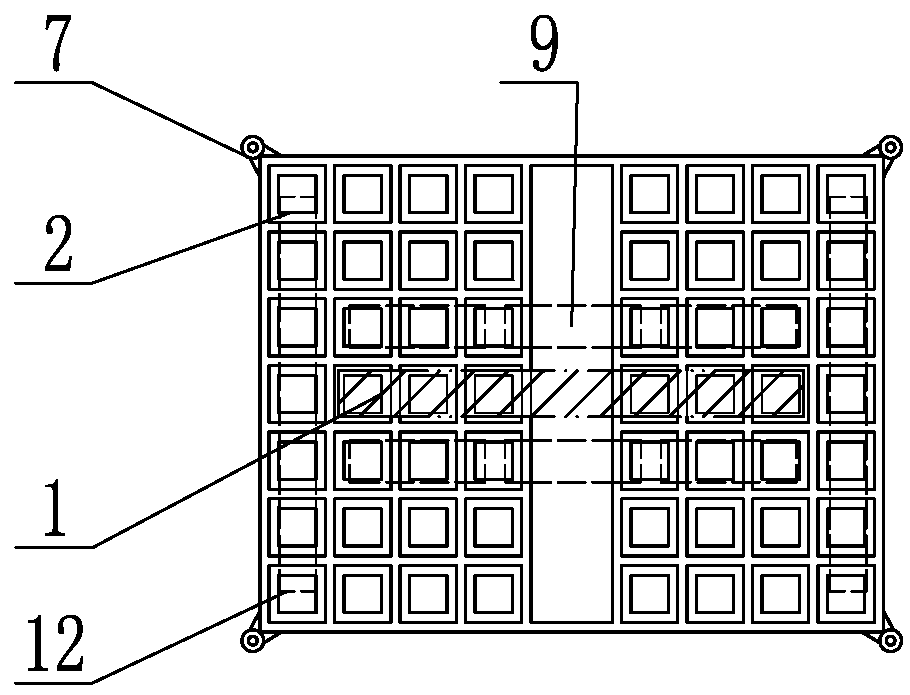

Image

Examples

Embodiment 1

[0078] 1) The chemical composition ratio (Wt%) of the material in Example 1 is shown in Table 4, and the balance is Fe and unavoidable impurities.

[0079] Table 4

[0080] C

Si

mn

P

S

Cr

V

Nb

Mo

Ni

Cu

0.49

O.26

0.85

0.012

0.003

0.99

0.06

0.03

0.20

0.05

0.12

[0081] 2) The metallurgical production process of the material of embodiment 1 is: according to the above 1) material composition (Wt%) batching, industrial production electric furnace smelting, furnace outer ladle refining and degassing treatment, mold casting, billet opening, pickling, grinding , rolling. Hot rolled material: 33x89mm flat steel.

[0082] 3) Fully decarburized layer depth, grain size and non-metallic inclusions (metallographic examination) of the material in Example 1: fully decarburized layer depth = 0 mm, and the grain size is grade 7. Heat preservation at 900°C (in air state), fully decarburized layer depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com