Washing machine inner drum and washing machine

A washing machine and inner tub technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of fouling, cannot be cleaned, and is difficult, achieve broad market prospects, good self-cleaning effect, and avoid breeding The effect of bacteria or accumulation of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A washing machine inner tub and a washing machine according to the present invention will be described in detail below in conjunction with the accompanying drawings:

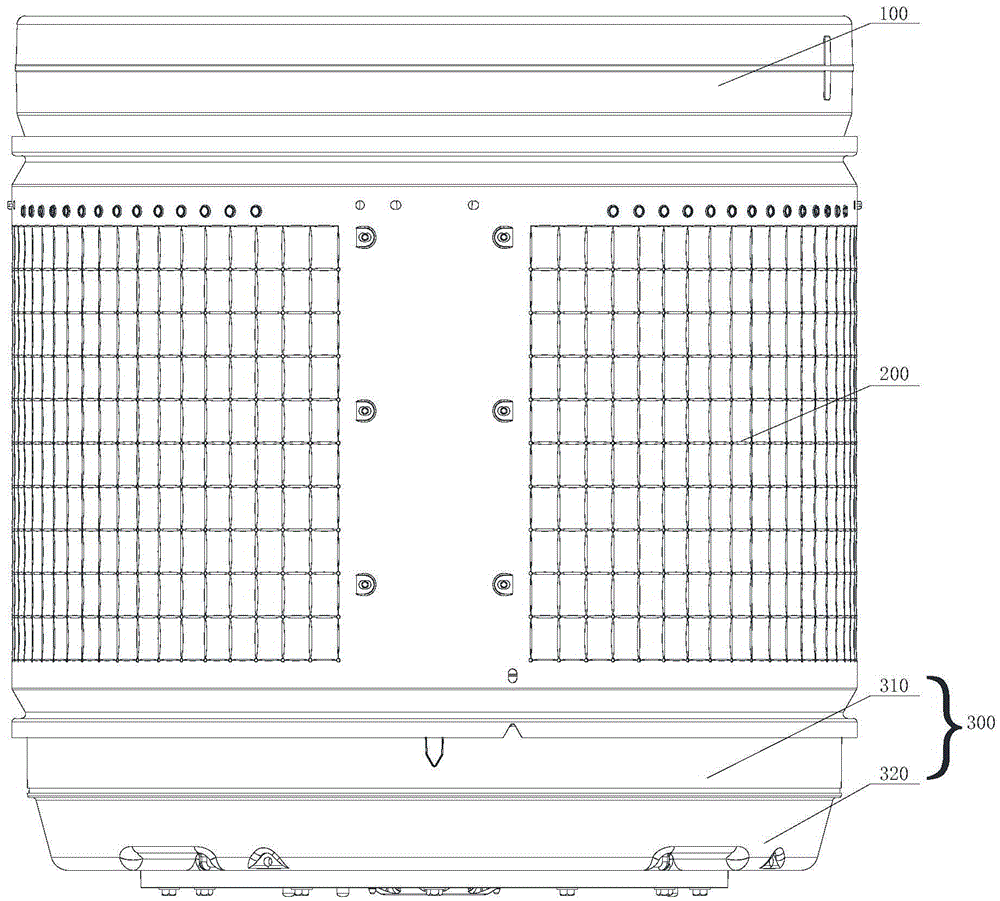

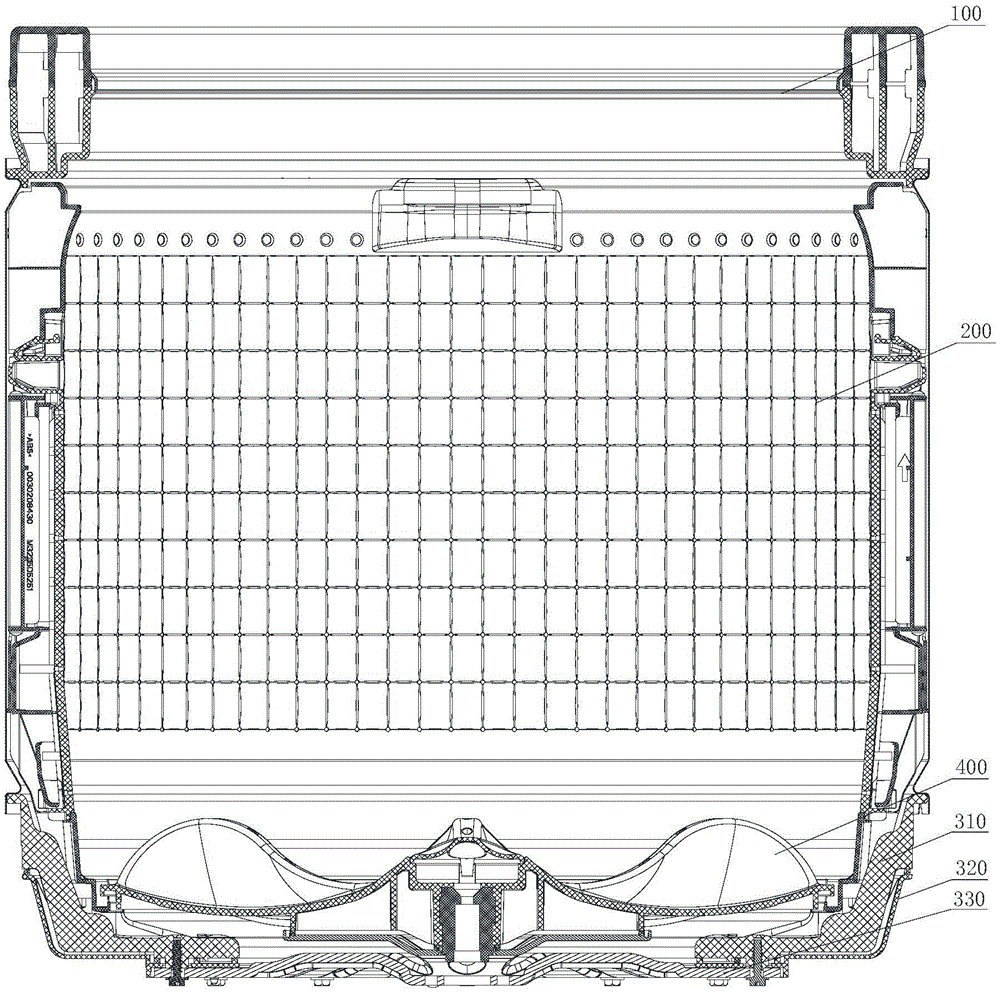

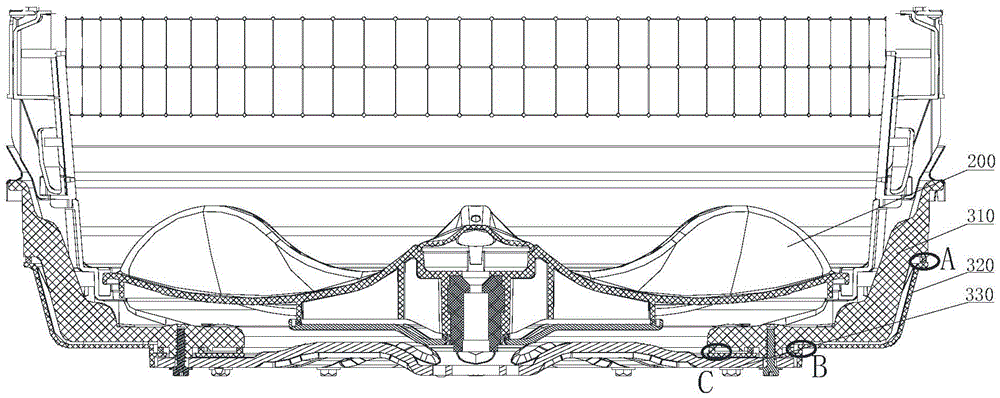

[0029] Such as figure 1 and figure 2 As shown, an inner tub of a washing machine includes a tub bottom 300 and a tub body 200 connected thereto. The tub bottom 300 includes a tub bottom body 310 and a tub bottom protective cover 320. The tub bottom protective cover 320 is sealed and covered. The entire outer surface of the tub bottom is made smooth at the bottom of the tub bottom body 310 .

[0030] The bucket body 200 and the bucket bottom 300 of the present invention form a bucket-shaped structure for holding laundry. The barrel body 200 is generally made of metal material, and the barrel bottom 300 is generally of plastic structure. Therefore, in order to ensure the strength of the bucket bottom 300 , a series of rib structures are provided at the bottom of the bucket bottom body 310 .

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com