A kind of black flame-retardant silk and preparation method thereof

A real silk and black technology, applied in the direction of flame-retardant fibers, textiles and papermaking, animal fibers, etc., can solve the problem of hard feel of real silk, and achieve the effect of good compatibility and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

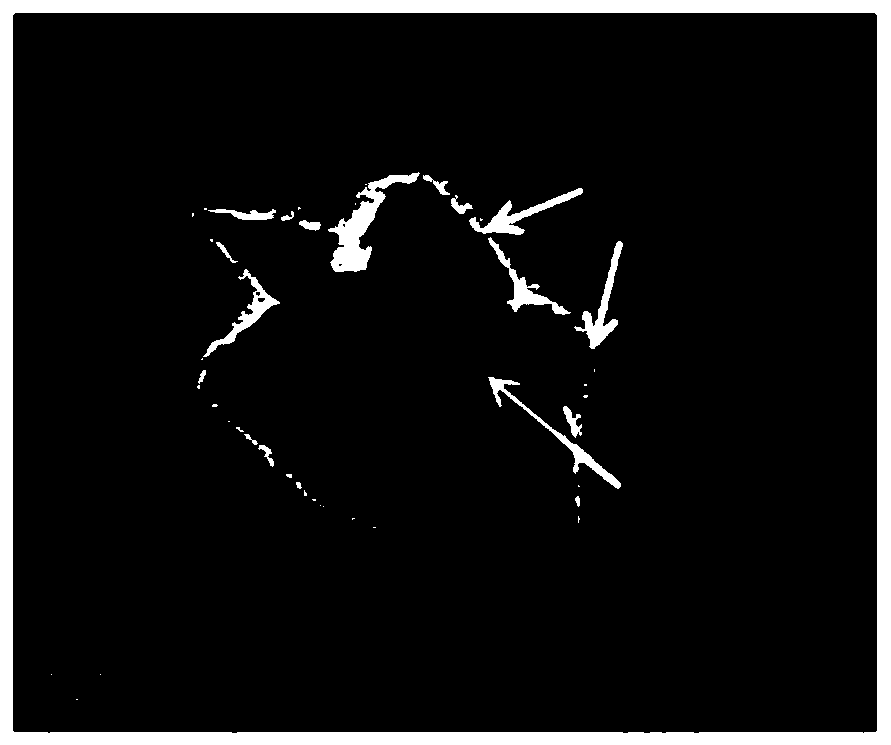

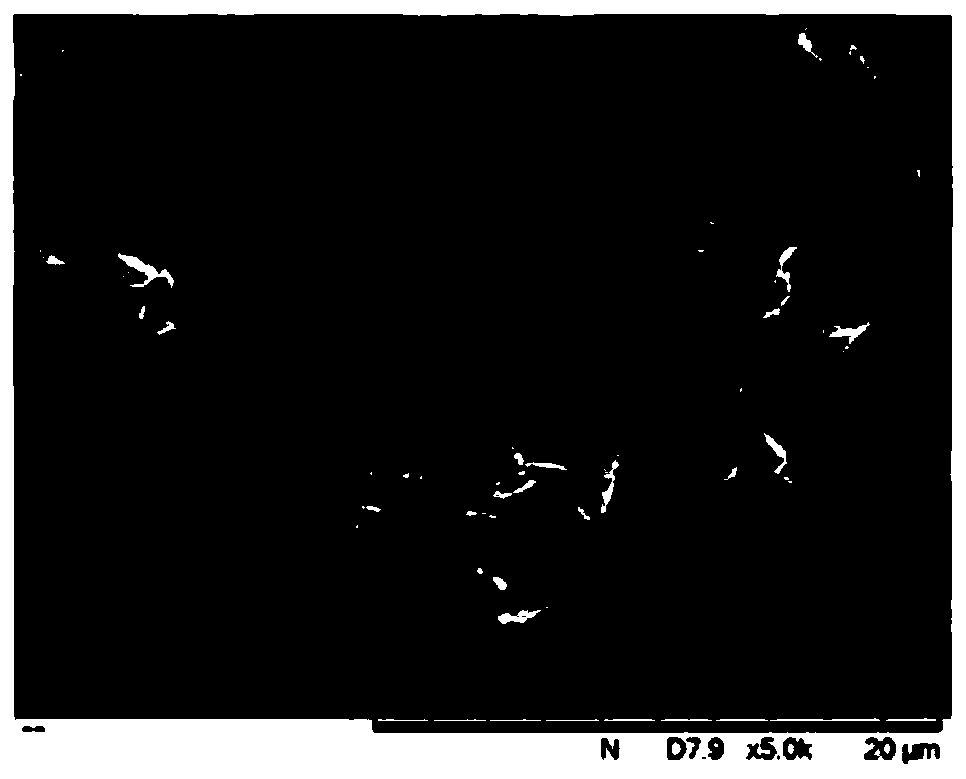

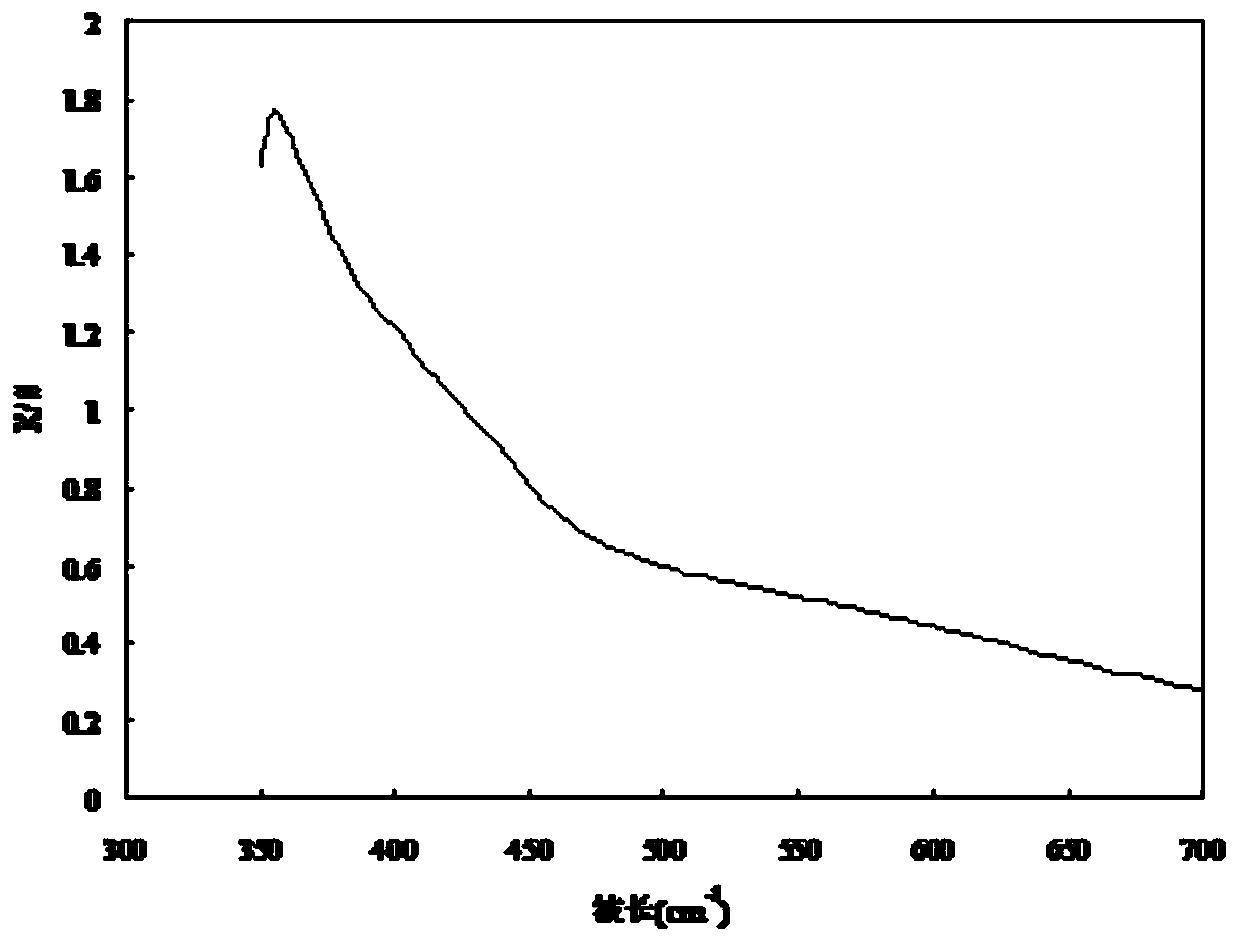

Embodiment 1

[0027] Weigh 1 g of ammonium polyphosphate and put it in a 100 ml small beaker, add polyethylene glycol 400 whose mass is 15% of the mass of ammonium polyphosphate, then add 25 ml of distilled water, and disperse ultrasonically for 5 minutes. Add 275ml of deionized water, weigh 0.3g of dopamine, then add ammonium polyphosphate suspension, use Tris and Tris-HCl to adjust the pH to 8.5, control the temperature of the reaction bath at 35°C, and continuously stir for 6 hours. Centrifuge and wash three times with water and three times with alcohol, store it in a reagent bottle, place it in an oven, adjust the temperature to 60°C, and dry it overnight. The obtained polydopamine microcapsules are made into a solution, the prepared microcapsules concentration is 2g / L, the buffer solution (Tris and Tris-HCl adjustment) with pH of 8.5 is put into silk whitening electric spinning, and the liquor ratio is 1 :50, shake in a water bath for 2 hours, and the temperature is 35°C. The real sil...

Embodiment 2

[0029] Weigh 1 g of ammonium polyphosphate and place it in a 100 ml small beaker, add polyethylene glycol 400 with a mass of 12% of the mass of ammonium polyphosphate, then add 25 ml of distilled water, and disperse ultrasonically for 5 minutes. Add 275ml of deionized water, weigh 0.3g of dopamine, then add ammonium polyphosphate suspension, use Tris and Tris-HCl to adjust the pH to 8.5, control the temperature of the reaction bath at 35°C, and continuously stir for 8 hours. Centrifuge, wash three times with water, wash three times with alcohol, store it in a reagent bottle, place it in an oven, adjust the temperature to 70°C, and dry it overnight. The obtained polydopamine microcapsules are made into a solution, the prepared microcapsules concentration is 4g / L, and the buffer solution (Tris and Tris-HCl adjustment) with a pH of 8.5 is put into the whitening power spinning of silk, and the bath ratio is 1 :50, shake in a water bath for 2 hours, and the temperature is 40°C. Th...

Embodiment 3

[0031] Weigh 1 g of ammonium polyphosphate and place it in a 100 ml small beaker, add polyethylene glycol 400 whose mass is 10% of the mass of ammonium polyphosphate, then add 25 ml of distilled water, and disperse ultrasonically for 10 minutes. Add 275ml of deionized water, weigh 0.75g of dopamine, then add ammonium polyphosphate suspension, use Tris and Tris-HCl to adjust the pH to 8.5, control the temperature of the reaction bath at 40°C, and continuously stir for 8 hours. Centrifuge, wash three times with water, wash three times with alcohol, store it in a reagent bottle, place it in an oven, adjust the temperature to 70°C, and dry it overnight. The obtained polydopamine microcapsules are made into a solution, the prepared microcapsules concentration is 2g / L, the buffer solution (Tris and Tris-HCl adjustment) with pH of 8.5 is put into silk whitening electric spinning, and the liquor ratio is 1 :40, shake in a water bath for 2 hours, and the temperature is 40°C. The real ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com