Core-inlaid type high manganese steel frog structure

A technology of high manganese steel and frogs, which is applied in the field of core-embedded high manganese steel frog structures, can solve problems such as peeling off of the surface layer of high manganese steel frogs, difficulty in repairing high manganese steel frogs, and affecting normal use. To achieve the effect of highlighting substantive features, safe and reliable use, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

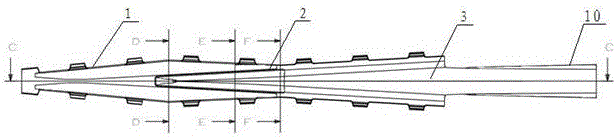

[0029] Specific embodiments: The present invention provides a core-inserted high-manganese steel frog structure, comprising a high-manganese steel frog body 1 and an inlay core 2. The high-manganese steel frog body 1 is integrally cast and includes wing rail connecting sections, The fork core section 3 and the fork heel rail connecting section 10, the wing rail connecting section and the fork heel rail connecting section 10 are respectively arranged at the front and rear ends of the fork core section 3, and the fork core section 3 is provided in front of the fork core section 3 to cooperate with the installation of the insert core 2. The installation slot 5, the high manganese steel frog body 1 and the insert core 2 are detachably connected.

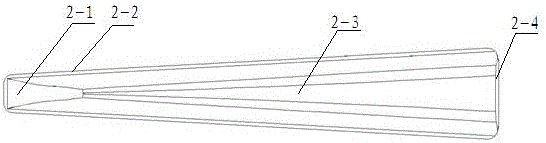

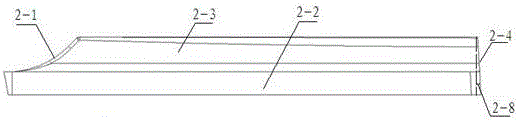

[0030] Wherein, the insert core 2 includes an upper connecting section 2-3 with a triangular top view, a lower connecting section 2-2 matedly connected with the mounting groove 5, and the tip of the upper connecting section 2-3 and the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com