Filling method for unreinforced light soil abutment back

A light-weight soil and light-weight technology, applied in buildings, roads, roads, etc., can solve problems such as non-destructive testing, affecting the stability and durability of light-weight soil subgrades, voids, etc., to improve bearing capacity and stability, It is beneficial to detect the quality of the project and improve the effect of the strength of the roadbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

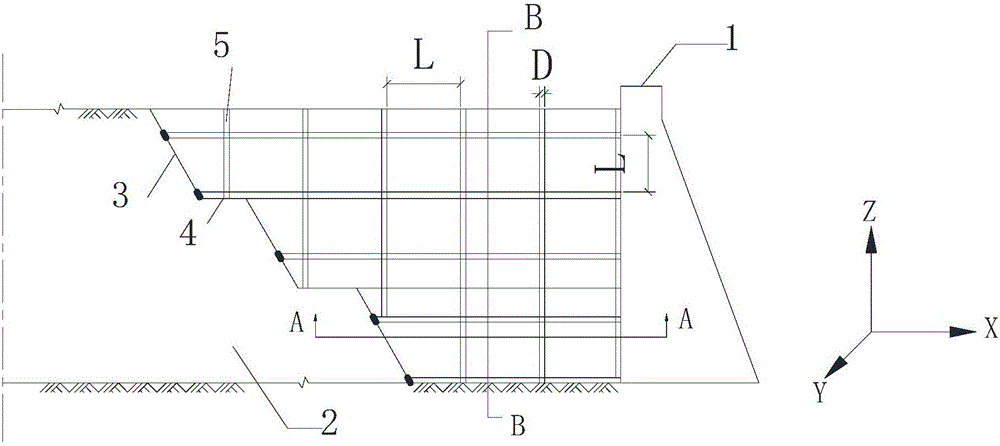

Method used

Image

Examples

Embodiment

[0054] In this example, during the normal maintenance process, the inside of the PVC pipe is saturated sand, the width of the road bed is W, and the length of the roadbed at the back of the platform is L u , when the gutter is filled with water, the capacity V is

[0055] V=2WL u h u (1)

[0056] There are about n horizontal outlets of PVC pipes on both sides of the roadbed, and the cross-sectional area of the outlets is

[0057] S=nπD 2 / 4 (2)

[0058] Gradually replenish the water stored in the slope protection vegetation soil through the saturated medium-coarse sand in the PVC pipe, and it takes about

[0059] t=V / kS (3)

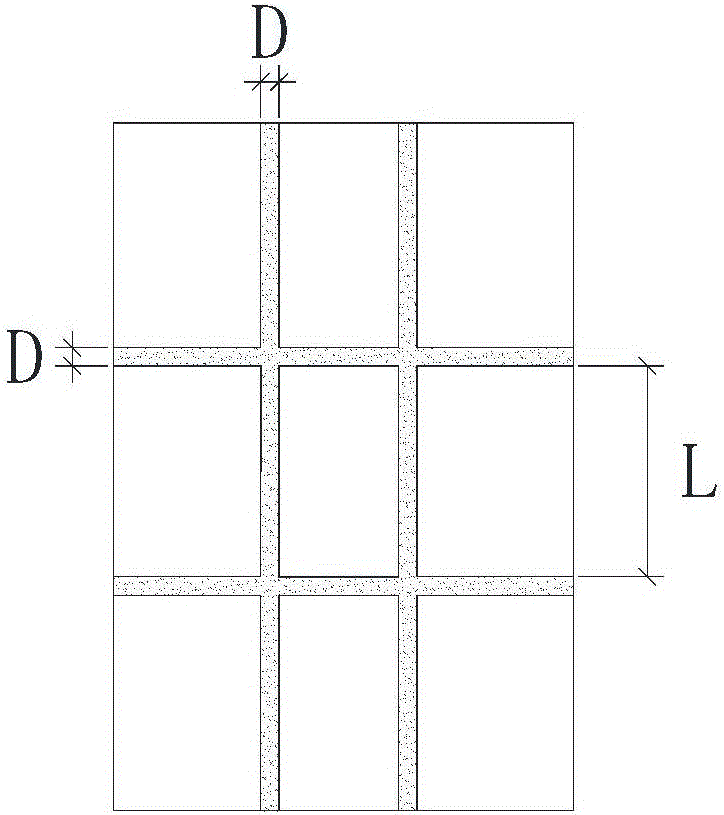

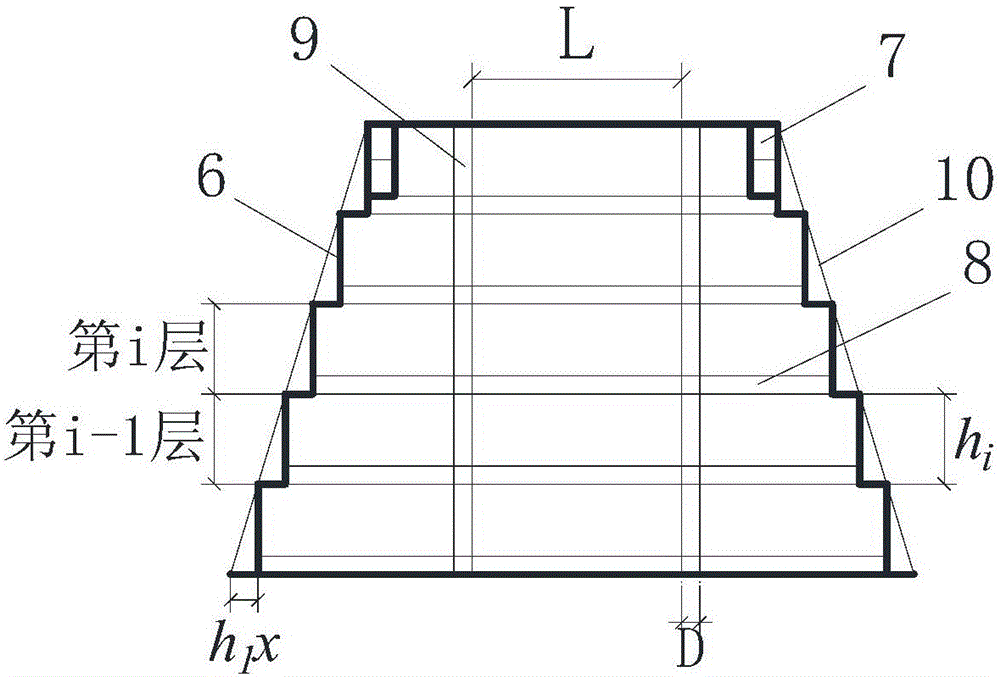

[0060] In this embodiment, the vertical and horizontal beams are arranged staggeredly in each layer, and there is a filling area in the middle. Each layer of light soil subgrade is simplified as a composite foundation, the vertical and horizontal beams are regarded as "cross piles", and the filled light soil is regarded as soil. Each layer The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com