Bottom bearing type folding truss bridge structure

A truss bridge and truss technology, applied in the directions of portable bridges, bridges, bridge parts, etc., can solve the problems of complex joints, poor rigidity, etc., and achieve the effect of overcoming numerous and messy rods, reasonable structure, and simple design and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below with reference to accompanying drawing of description, the present invention is described in more detail:

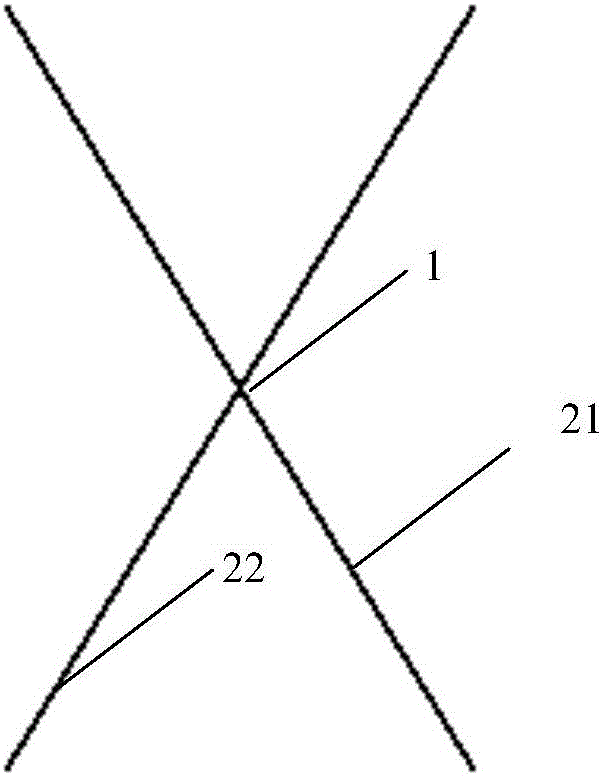

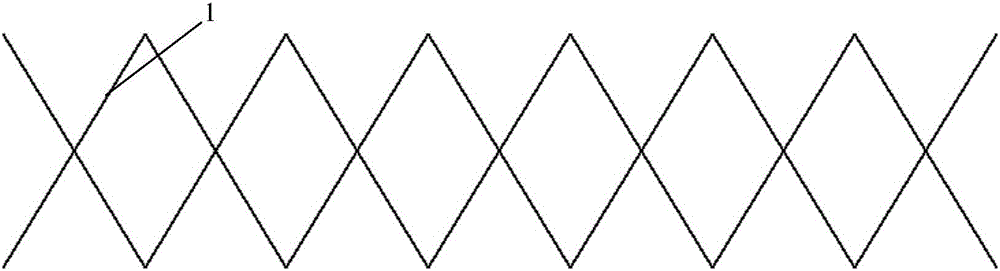

[0020] Scissor unit 1 in the structural span figure 1 As shown, a scissor unit is formed by pinning two straight rods 21 and 22 at the midpoint of the two rods. Such as figure 2 , the scissor units 1 are connected in the length direction of the structure to form a folded truss unit 4 .

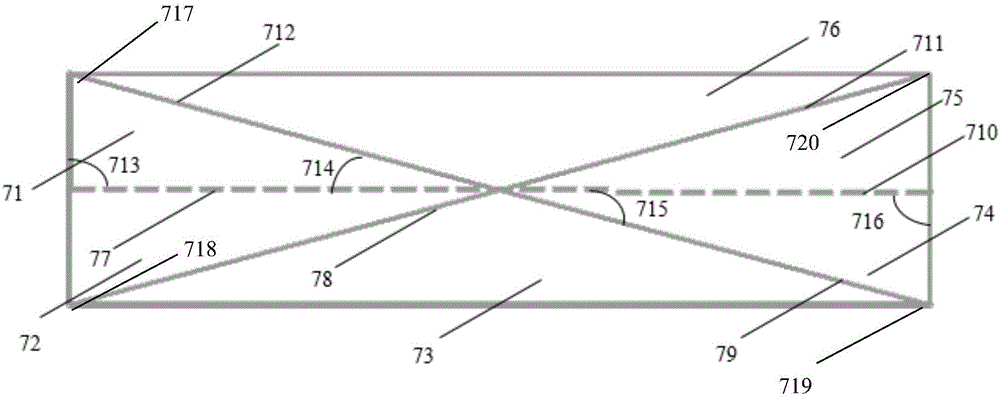

[0021] When the structure is unfolded, the cables 3 are tightened, and the cables are arranged on the upper and lower edges of a folded truss unit 4. The folded truss of the cables is as follows: Figure 5 shown.

[0022] The rigid bridge deck 5 is composed of rigid bridge deck subunits 6 connected together. The rigid bridge deck subunits are arranged under the two folded truss units 4 . The rigid bridge deck subunit 6 is fully deployed as image 3 As shown, half-expanded as Figure 4 shown. Each rigid bridge deck subunit 6 is composed of six triangular plates 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com