Wall plastering machine and upright jacking device thereof

A technology of jacking device and wall plastering machine, which is applied in the direction of construction and building construction, and can solve problems such as uneven application of cement mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

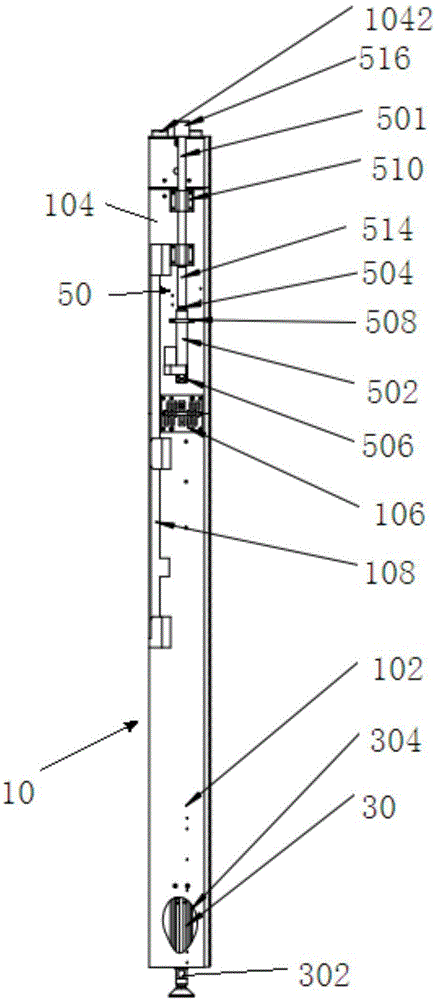

[0019] see figure 1 , The wall plastering machine according to one embodiment of the present invention includes a chassis (not shown), a column 10 connected to the chassis, and a column jacking device (not shown). The column jacking device includes a jacking mechanism 30 and a resisting mechanism 50. The jacking mechanism 30 is connected to the column 10 to drive the column 10 to lift. It can extend to the top of the column 10 to guide the column 10 when the column 10 rises. Before the jacking mechanism 30 drives the column 10 to rise, the telescopic part 501 stretches out relative to the column 10 to expose the top of the column 10, and the top of the telescopic part 501 is against the ceiling, and then the jacking mechanism 30 is started, so that the column 10 During the rising process, the resisting mechanism 50 can guide the column 10 .

[0020] In this column jacking device and wall plastering machine, since the telescopic part 501 of the resisting mechanism 50 can guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com