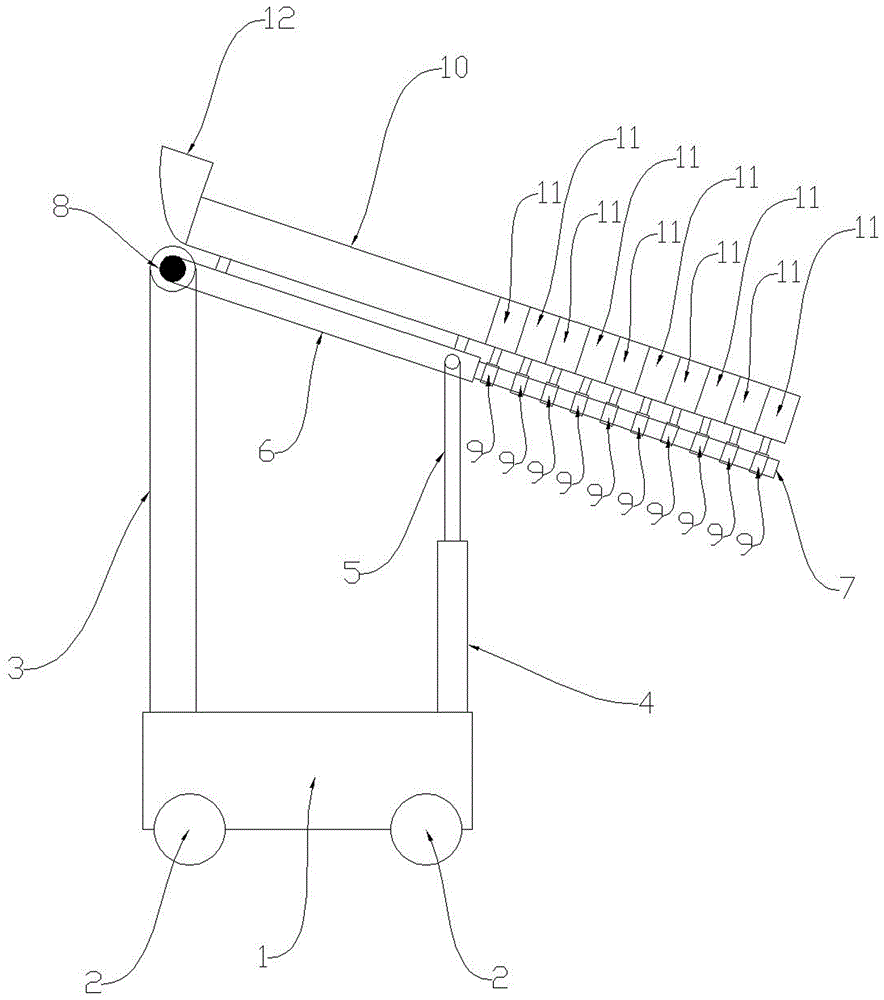

Telescopic mobile chute tube

A mobile, sliding drum technology, applied in the field of concrete pouring, can solve the problems of low pouring efficiency, high labor intensity of workers, waste of concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

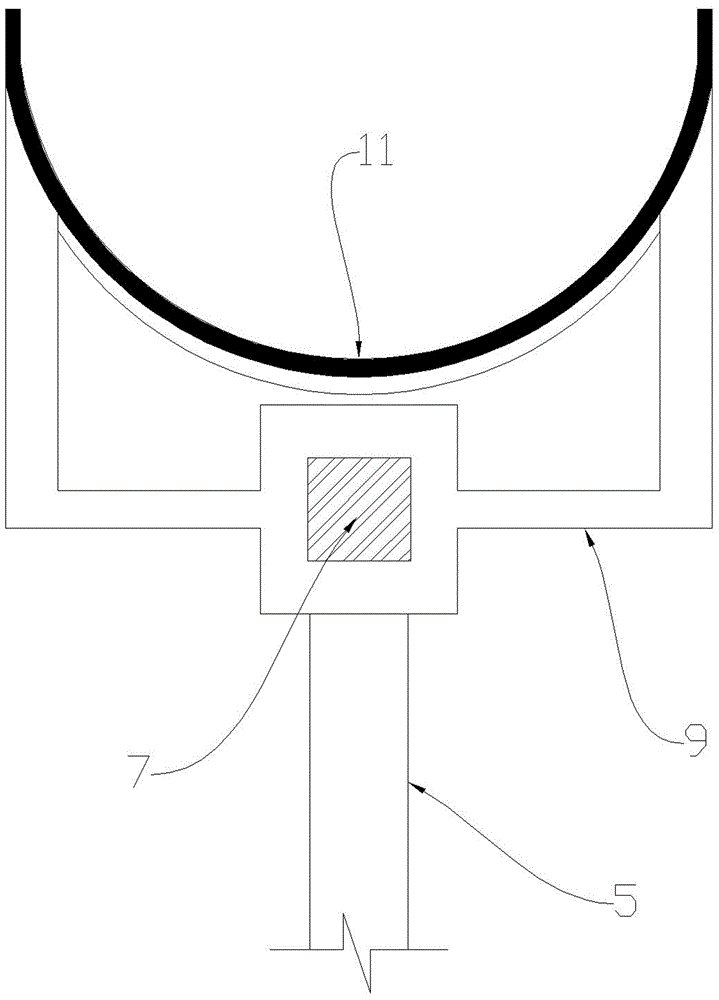

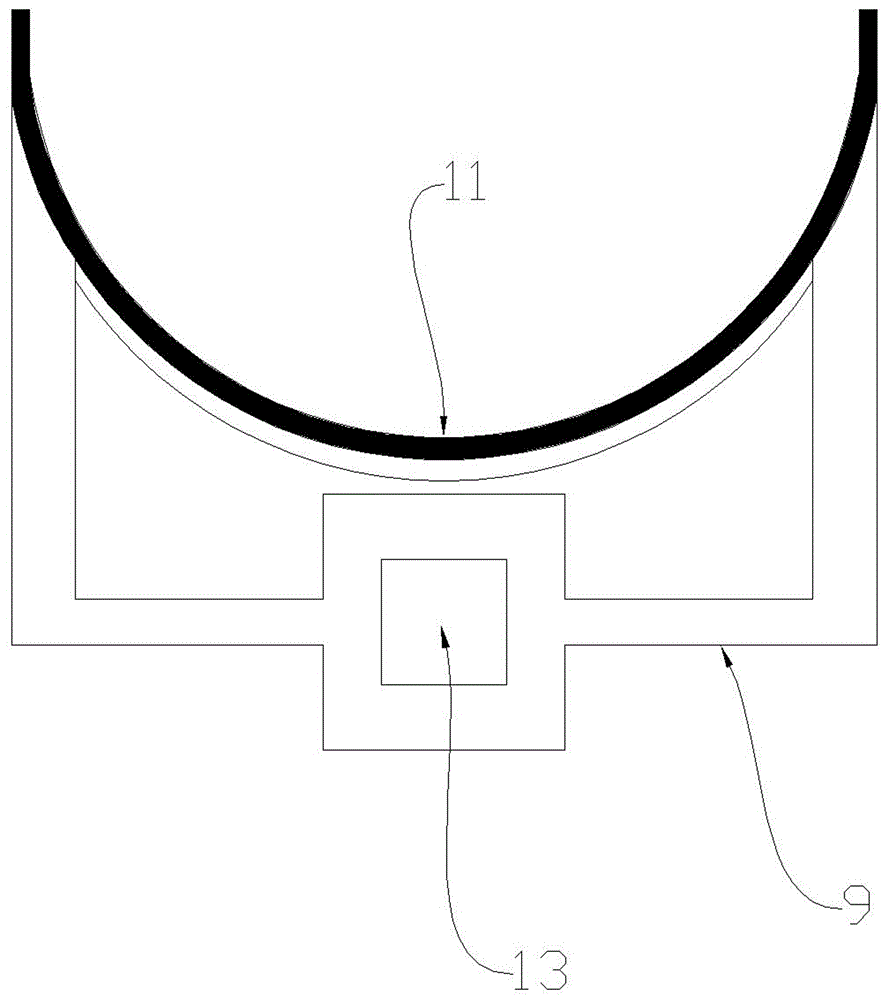

[0010] Summary of the Invention The specific implementation of the present invention has been described in detail, and will not be repeated here; it should be noted that the shaft section of the telescopic rod 7 matches the hole 13, and the shaft section of the telescopic rod 7 is either square or oval. Or any other shape except the circle, because if the shaft section of the telescopic rod 7 is circular, the hole 13 of the movable frame 9 can rotate around the telescopic rod 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com