Method for blocking strong water washing by injecting blocking agent into thick reservoir by means of fracture

A technology of plugging agent and thick oil layer, applied in the direction of sealing/isolation, earthwork drilling and production, wellbore/well parts, etc., it can solve the problem of poor plugging effect, short plugging distance and weak plugging of strong water washing strips and other problems, to achieve the effects of obvious plugging effect, decreased liquid production, and low equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

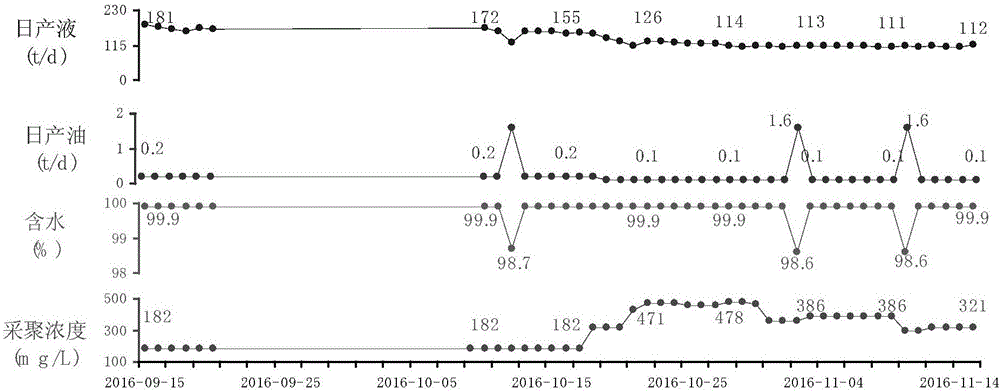

[0048] The present invention will be further described in conjunction with well B1-6-P68, a type of thick oil layer in Changyuan, Daqing.

[0049] Well B1-6-P68 is an old production well after polymer flooding, and it was drilled on October 10, 1996. The oil-water well spacing of this well is 175m, the well depth is 1166.71m, and the perforated section depth is 1068.9-1097.7m. A total of 9 sublayers from Pu I1 to Sa I7 have been penetrated, including the Pu I2 sublayer.

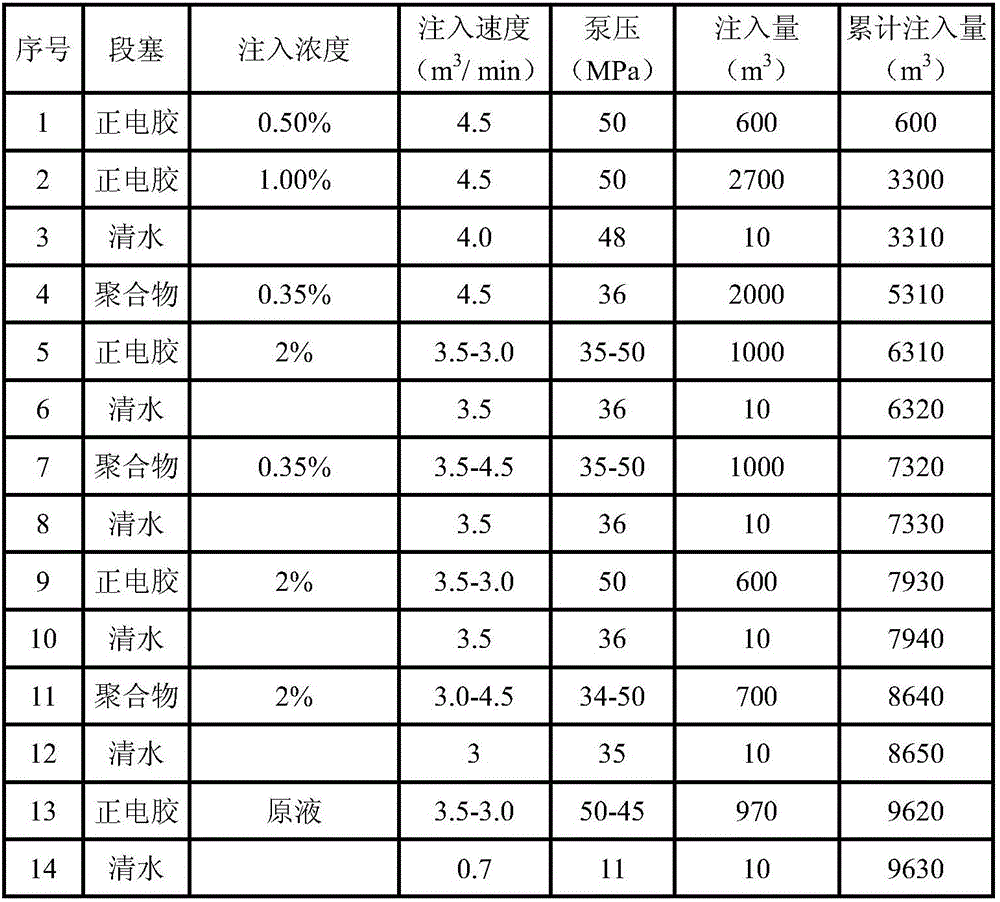

[0050] (1) Determine the target layer for plugging: According to reservoir logging interpretation, water flooding interpretation, fine description, profile test data, coring well data, and production dynamic data analysis, it is determined that the bottom 2.6m of the Pu I2 sublayer of the well is 1074.3 ~1076.9m is a strong water washing strip, which is determined as the target layer of this fracturing plugging construction, and multi-stage long rubber tubes are used for construction control;

[0051] (2) De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com