Waste goaf coalbed methane ultimate exhausting and mining method

A goaf and coalbed methane technology, which is applied in the fields of fluid extraction, earthwork drilling, climate sustainability, etc., can solve the problems of inability to extract coalbed methane and the extraction effect is not ideal, so as to shorten the extraction time, Mitigating the effect of the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the example of the present invention will be further described:

[0013] A coalbed methane limit extraction method in an abandoned goaf, comprising the following steps:

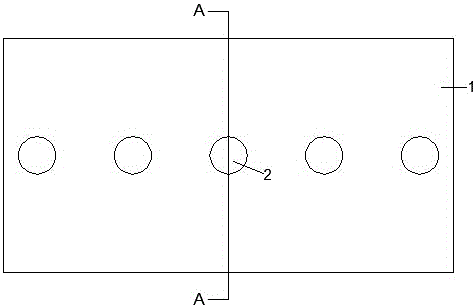

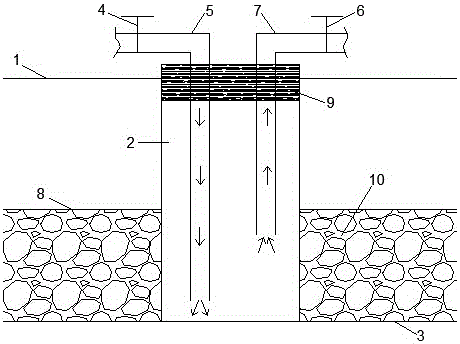

[0014] a. Construct a ground borehole (2) at intervals of 100-150m from the ground (1) along the middle of the goaf mining direction to the bottom of the goaf (3);

[0015] b. Insert a gas injection pipe (5) with a first valve (4) at the upper end into each ground borehole (2) to the bottom of the goaf (3), and then insert into each ground borehole (2) Insert a drainage pipe (7) with a second valve (6) on the upper part to the upper boundary (8) of the goaf, and seal the hole of the ground borehole (2) with a sealing material (9);

[0016] c. Open the first valve (4) and the second valve (6), inject carbon dioxide into the goaf (10) through the gas injection pipe (5), and at the same time drain the gob (10) through the extraction pipe (7) coalbed methan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com