Perforating bullet improving tunnel flow conductivity

A technology of diversion capacity and perforating bullets, which is applied in the direction of warheads, ammunition, projectiles, etc., can solve problems such as clogging of pestle body, increase of small debris between particles, and decrease of average permeability, so as to reduce clogging, increase production capacity, The effect of increasing the channel conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

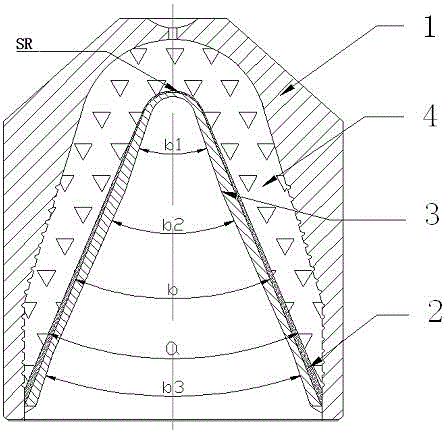

[0015] The invention provides a perforating charge that improves the flow conductivity of the tunnel. The perforating charge can remove the perforation compaction zone and reduce the clogging of the perforating pestle in the process of forming the perforation tunnel, so as to realize clean perforation and increase Pore conductivity, the effect of improving the productivity of oil and gas wells.

[0016] Embodiments of the present invention will be described in detail below in conjunction with the following drawings.

[0017] Specifically, such as figure 1 As shown, a perforating charge that improves the flow conductivity of the channel includes an internal projectile body 1, and the projectile body 1 is provided with an energetic material liner 2 and an energy-gathering perforating liner 3. The energetic material liner 2 and the Explosives 4 are also filled between the inner cavities of the missile body 1 .

[0018] Wherein, the top section of the inner cavity of the proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com