Waterproofing method for supporting roller bearing pedestals on steel plate cold rolling line

A technology of cold-rolled steel plates and backup rolls, applied in the directions of bearing elements, shafts and bearings, rigid supports of bearing parts, etc., can solve the problem of not finding the cause of water ingress and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

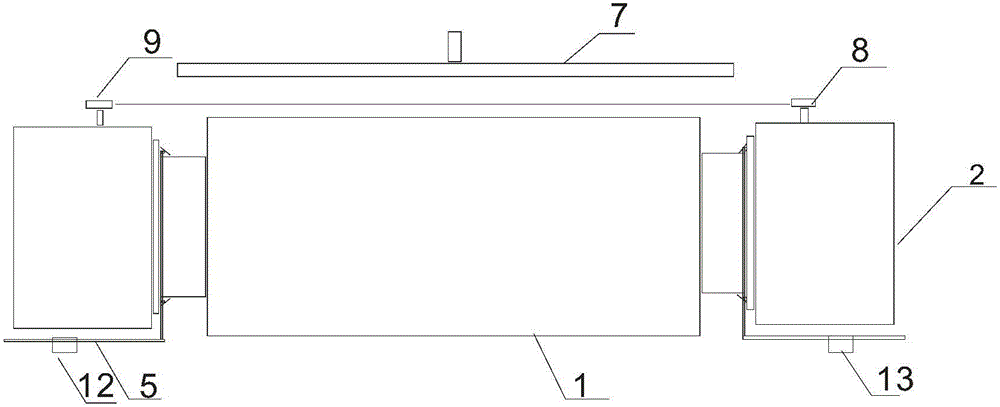

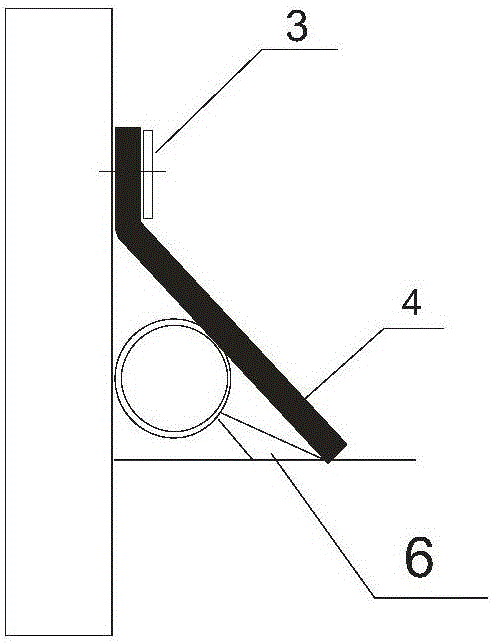

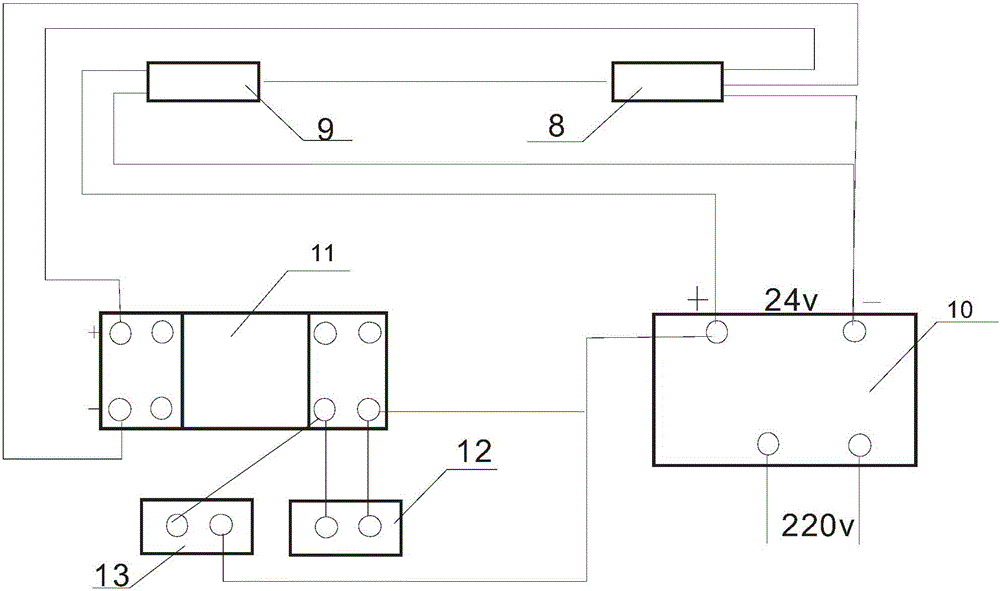

[0017] Such as figure 1 , figure 2 As shown, it is the installation position diagram of the cold-rolled steel wire back-up roll bearing housing waterproof method. The two ends of the support roll of item 1 are the bearing housings of item 2. Inside the bearing housing of item 2, there is a flange pressure plate of item 3, and the pressure plate is fixed. Housing part 4 waterproof rubber plate, this rubber plate is to prevent the cooling medium from spraying on the shaft, in an attempt to block the medium from entering the inside of the bearing seat, the actual effect is to reduce the amount of cooling medium splashed on the shaft, and it cannot prevent water from flowing with the shaft at all. The rotation enters the bearing seat. Below part 4 waterproof rubber is part 5 gas purge pipe, with a circular tube of diameter 20mm, simmers and makes an annulus, and its diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com