Synchronizers and Gearboxes

A technology for synchronizers and gearboxes, applied to clutches, mechanical drive clutches, components with teeth, etc., can solve problems that affect driving safety, wrong gears, and the outer ring cannot decelerate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

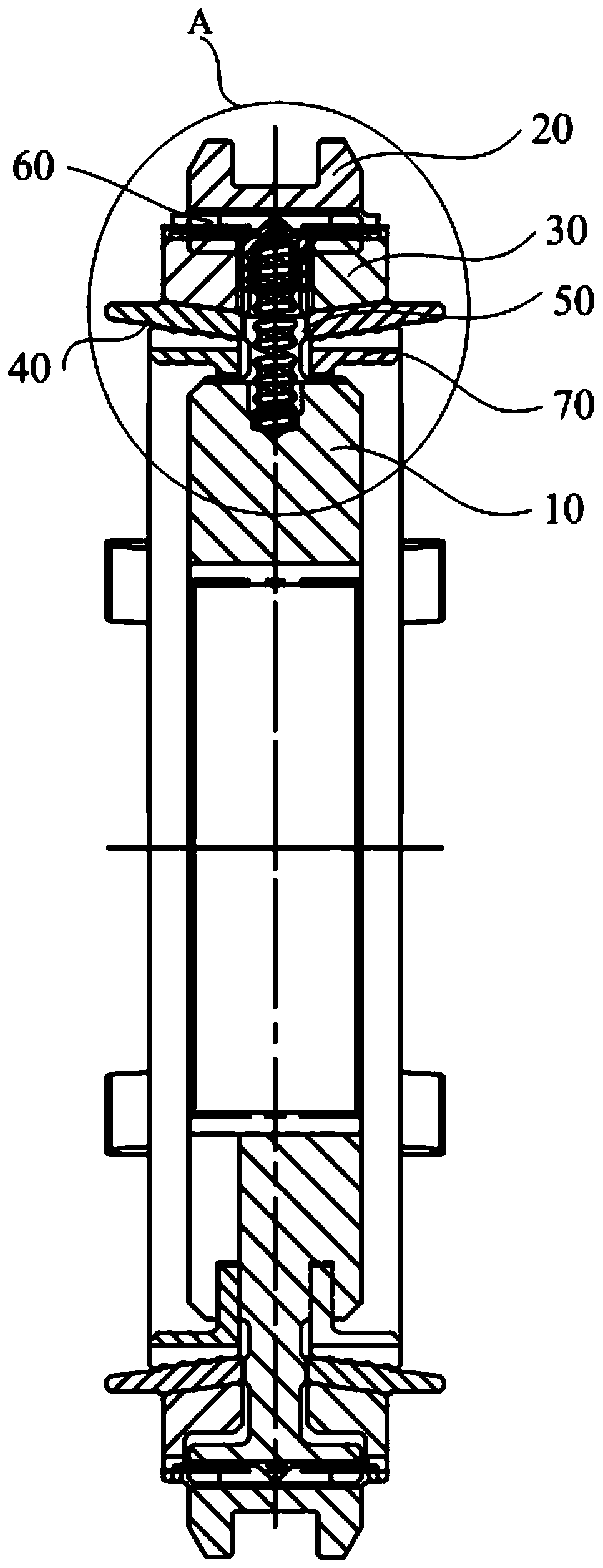

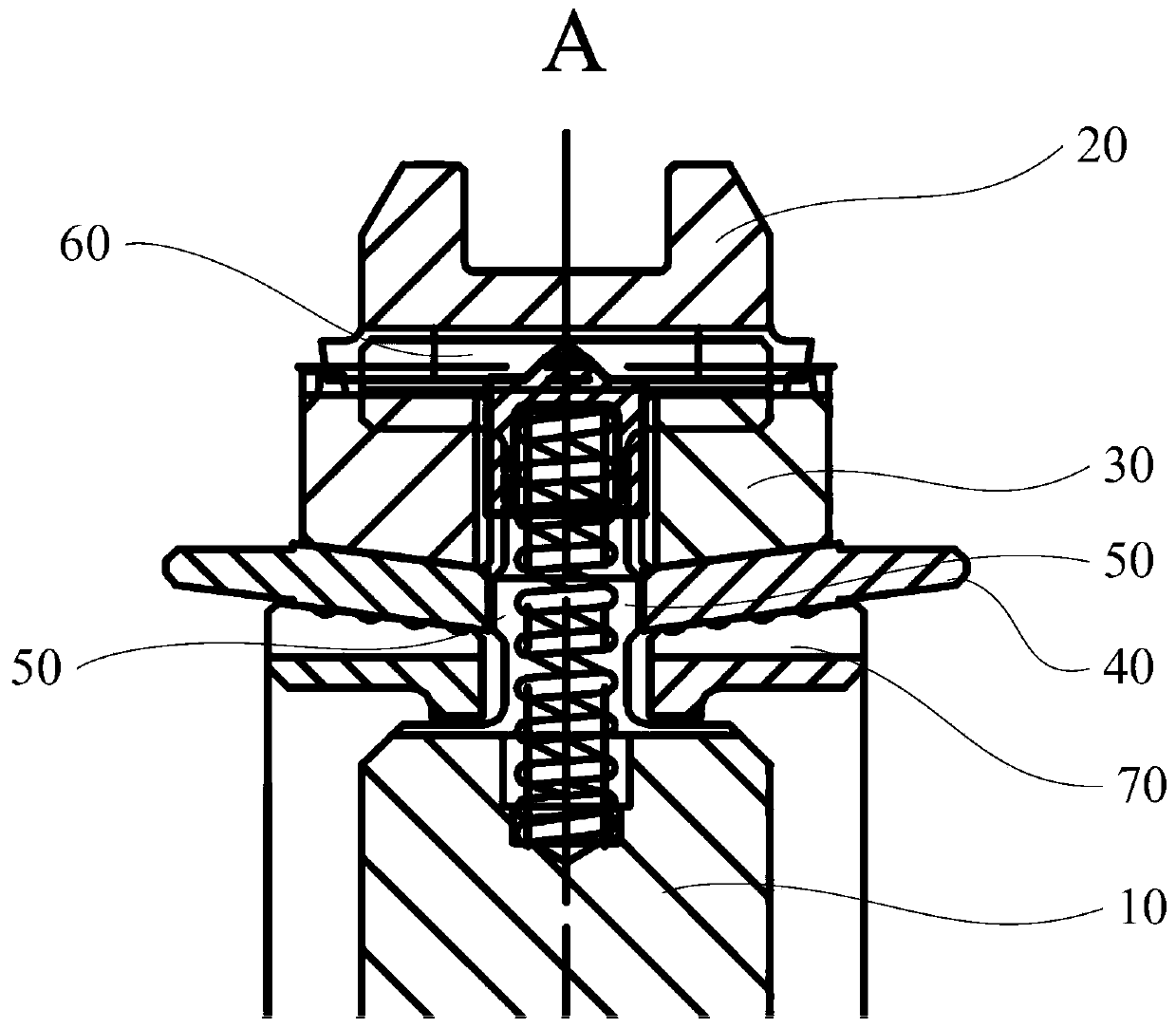

Image

Examples

Embodiment

[0061] When it is necessary to shift gears from the right gear to the left gear: before gear shifting is started, the synchronizer gear sleeve 20 is located on the right side, and the middle ring 40 on the right side has a combination tooth matched with it at this moment. Speed, the middle ring 40 on the right transmits the speed to the outer ring 30 and inner ring 70 on the right through the tapered surface, and drives the gear hub 10 to have the same speed as the right coupling teeth; When the left gear is in gear, the synchronizer gear sleeve 20 starts to move from right to left, and the synchronizer gear sleeve 20 drives the lower outer ring 30 to move through the slider 60, and the outer ring 30 drives the middle ring in turn through friction. 40 and inner ring 70 move from right to left, at this moment, because the width of middle ring 40 is longer, the part protruding on it does not disengage from engaging tooth, so three-piece set (inner ring 70, middle ring 40 and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com