Method for slowly releasing shock in two directions

A technology of one-way valve and outer cylinder, which is applied in the direction of shock absorber, spring, spring/shock absorber, etc., can solve the problems such as unable to provide return force, achieve stable and reliable working process, realize equalization, and realize two end-back effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

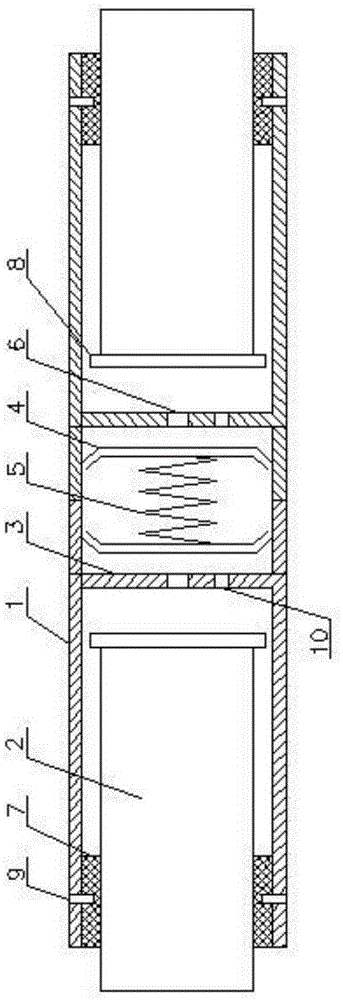

[0030] Such as figure 1 As shown, the two-way shock release method utilizes the equipment described below:

[0031] The device includes an outer cylinder 1, a compression column 2, a damping plate 3, a floating piston 4 and a spring 5; the outer cylinder 1 is arranged horizontally, both ends of the outer cylinder 1 are open, and two damping plates 3 are symmetrically arranged on the outer cylinder In 1, two floating pistons 4 are relatively arranged between two damping plates 3, and the two floating pistons 4 are connected by a spring 5; two compression columns 2 are respectively inserted into the outer cylinder 1 through both ends of the outer cylinder 1; The damping plate 3 is provided with a damping hole 6; the damping plate 3 is provided with a one-way valve 10 leading to the end of the outer cylinder 1.

[0032] The specific method is as follows:

[0033] Inside the outer cylinder 1, the space between the end of the compression column 2 and the damping plate 3 is filled...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the sealing support body 7 is used for sealing between the outer cylinder body 1 and the compression column 2 .

[0038] A sealing support member 7 is provided to avoid oil leakage in the outer cylinder.

Embodiment 3

[0040] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 2, a retaining ring 8 is provided on the outer circular surface of one end of the compression column 2 inside the outer cylinder 1 .

[0041] A retaining ring 8 is provided to prevent the compression column 2 from detaching from the outer cylinder 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com