Design method for automatic full balance of main motion inertia force of high speed gear shaping machine

A design method and inertial force technology, applied in the direction of inertial force compensation, mechanical equipment, transmission devices, etc., can solve the problems of parts accuracy not meeting the requirements, low efficiency, low stroke speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

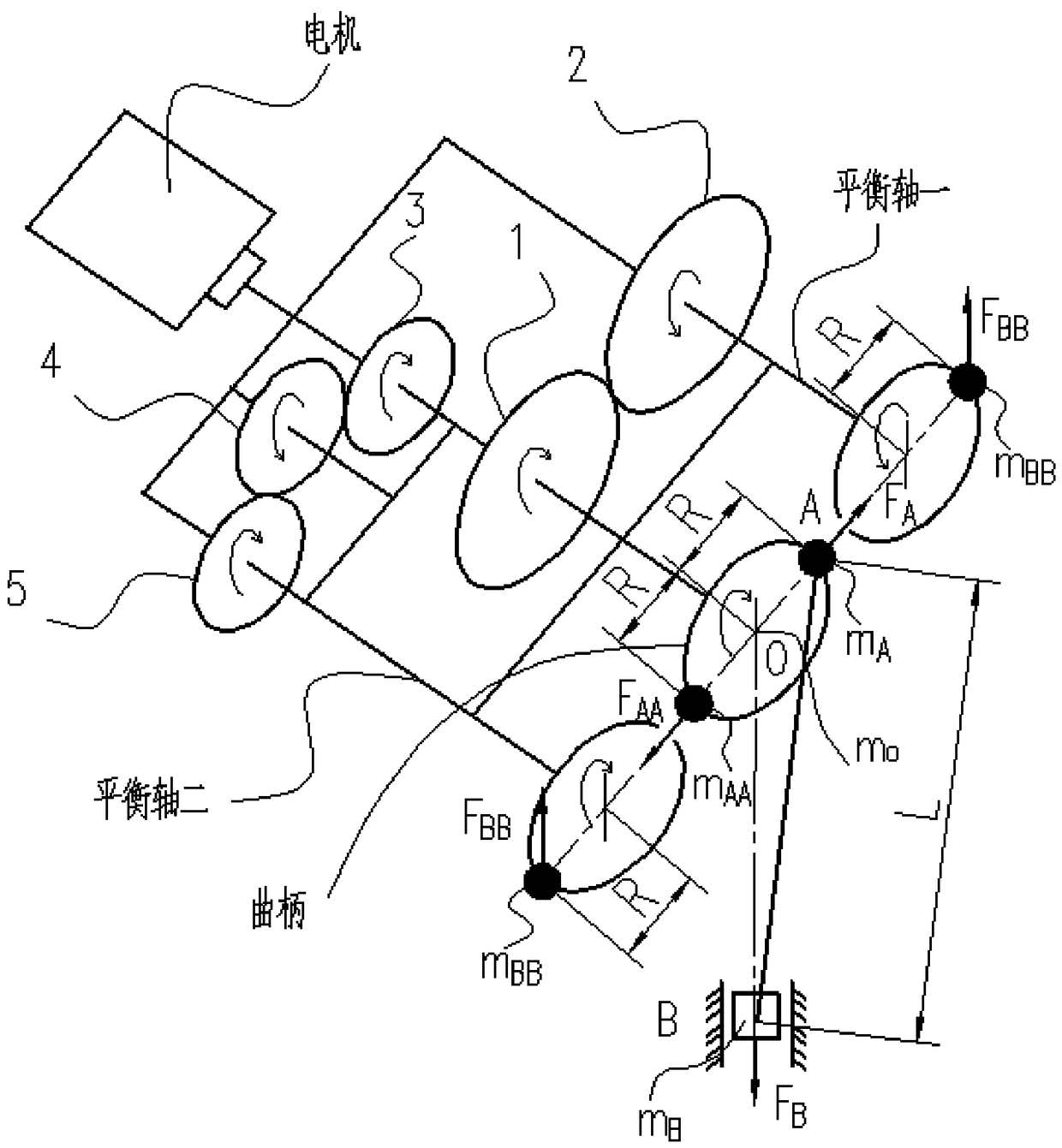

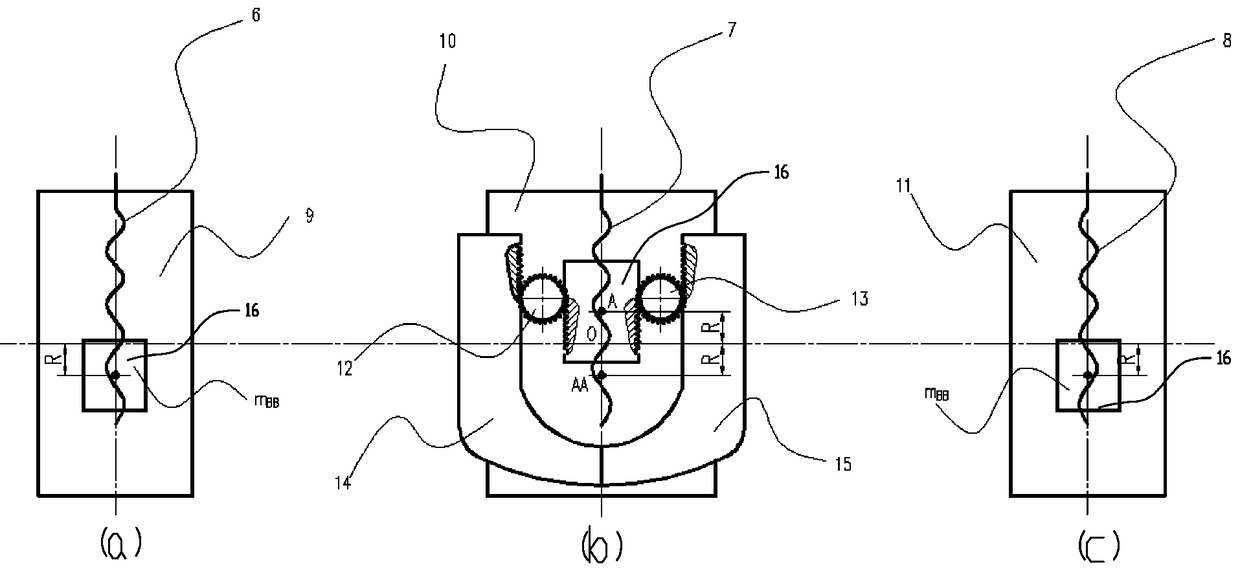

[0046] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

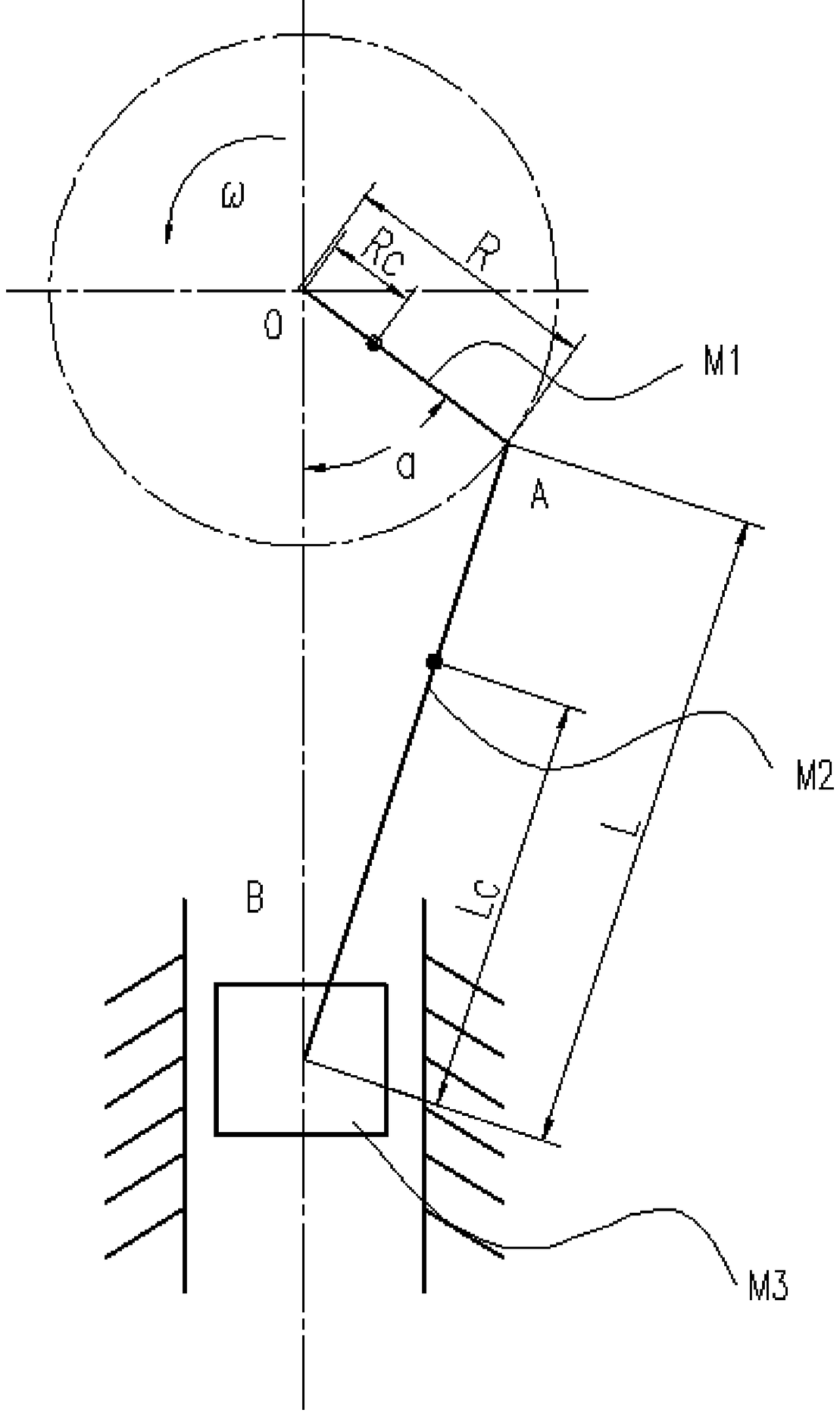

[0047] like Figure 1-3 , a high-speed gear shaping machine main motion inertial force automatic full balance design method, characterized in that it includes the following steps:

[0048] Step 1: Establish the displacement S, velocity V and acceleration α of the mechanism slider through the dynamic analysis of the centering upright slider crank mechanism 3 The mathematical models of are:

[0049]

[0050]

[0051] alpha 3 =Rω 2 (cosα+λcos2α) (3)

[0052] In the formula: λ=R / L; R is the length of the crank; ω is the constant rotational angular velocity of the crank; α is the rotation angle; L is the length of the connecting rod.

[0053] Step 2: According to the mass static substitution method that keeps the inertial force constant, the mass M of the crank is 1 With two lumped masses M centered at point O at the center of the crank and at poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com