Knob-type two-way valve

A two-way valve, knob type technology, applied in the field of hydraulic valves, can solve the problems of gaps between the valve cover and the interface, valve leakage, increased pressure difference at the fluid output end, etc., to achieve the effect of easy operation of the rotating shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

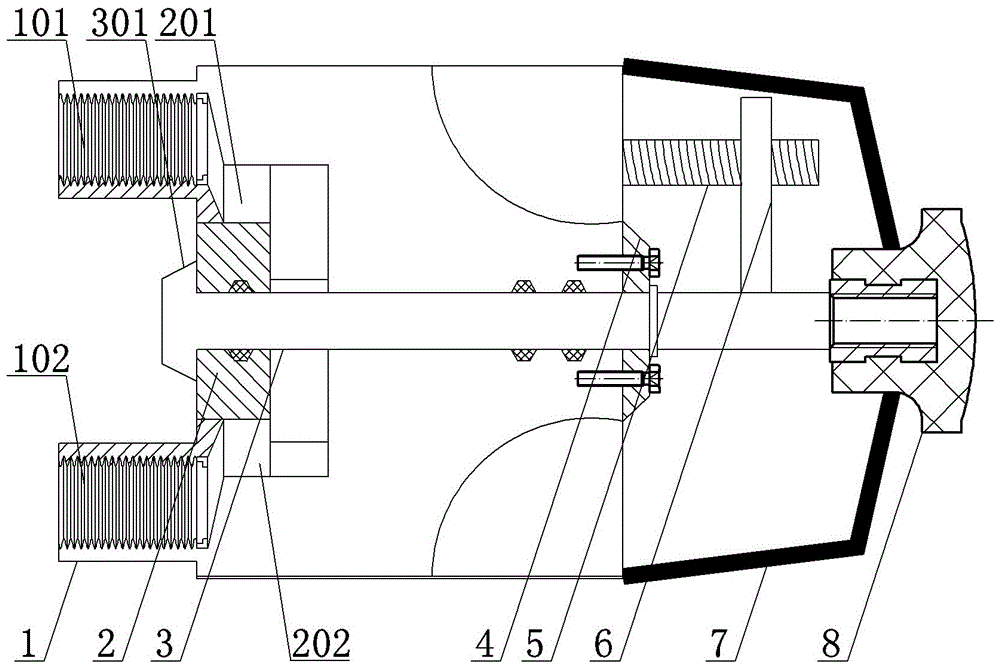

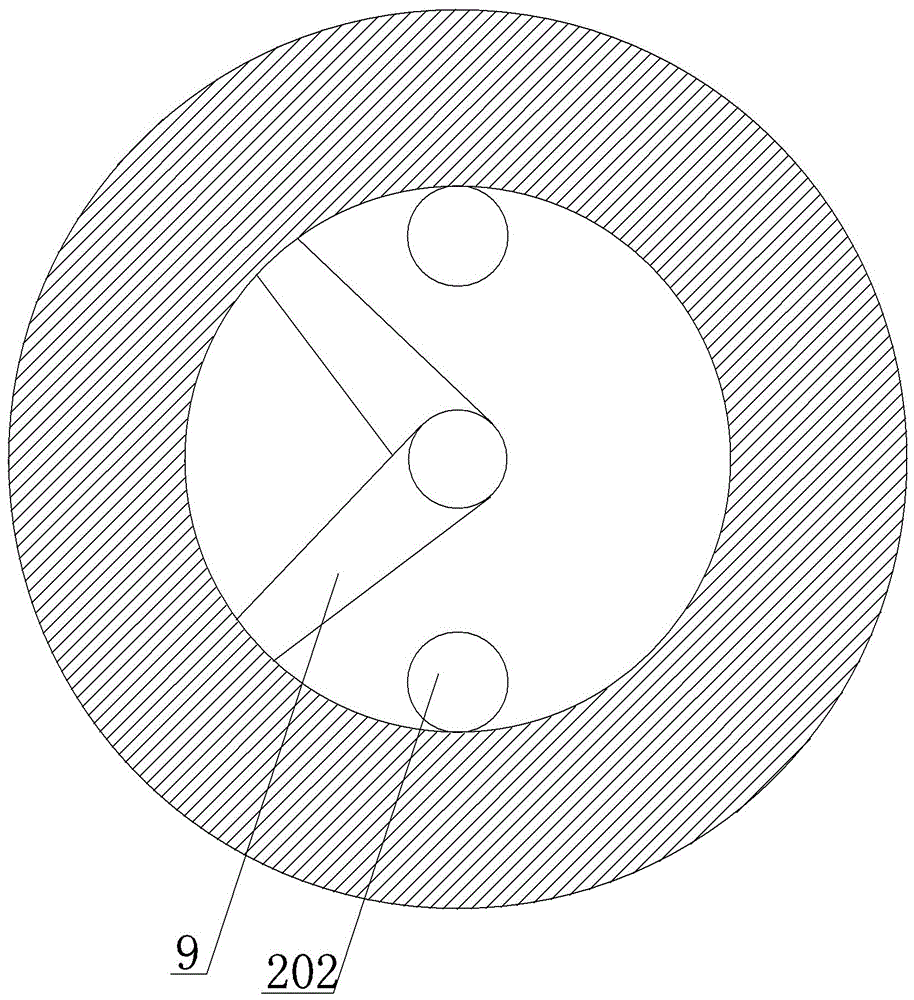

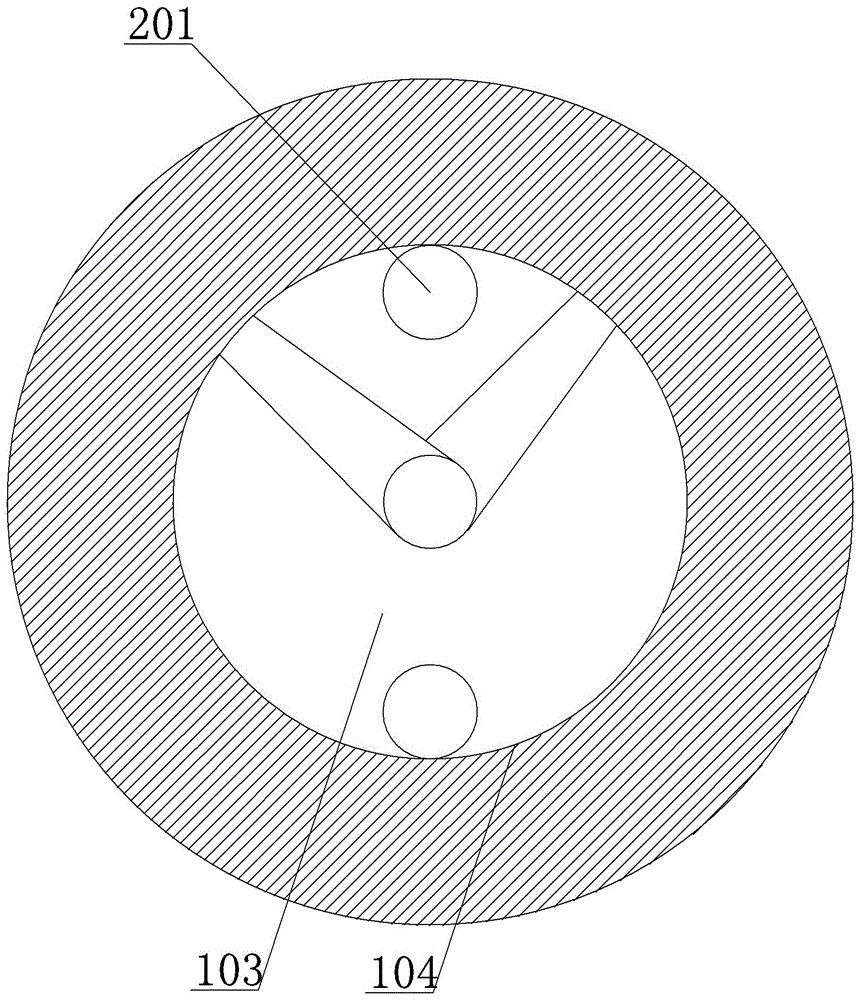

[0019] The reference signs in the manual include: valve body 1, sealing sleeve 2, rotating shaft 3, cover 4, electromagnetic coil 5, bar armature 6, insulating shell 7, embossed handle 8, sliding flap 9, compression spring 10, oil inlet 101 , oil outlet 102 , rotary oil chamber 103 , outer peripheral wall 104 of the concave inner cavity, oil inlet hole 201 , oil outlet hole 202 .

[0020] The embodiment is basically as figure 1 and figure 2 Shown: a knob-type two-way valve, including a valve body 1, a cylindrical concave inner cavity is formed on the valve body 1, and a rotating shaft 3 is rotatably connected to the valve body 1, and the rotating shaft 3 is perpendicular to the concave inner cavity. The center of the rotary surface is inserted into the valve body 1 through. A step is formed on the end of the rotating shaft 3 close to the recessed inner cavity, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com