Feeding speed-adjustable fuel feeding mechanism

A technology of feeding mechanism and feeding speed, applied in the direction of adjusting fuel supply, fuel supply, combustion method, etc., can solve the problems of inconvenient feeding and unadjustable fuel feeding speed, and achieve the effect of simple and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

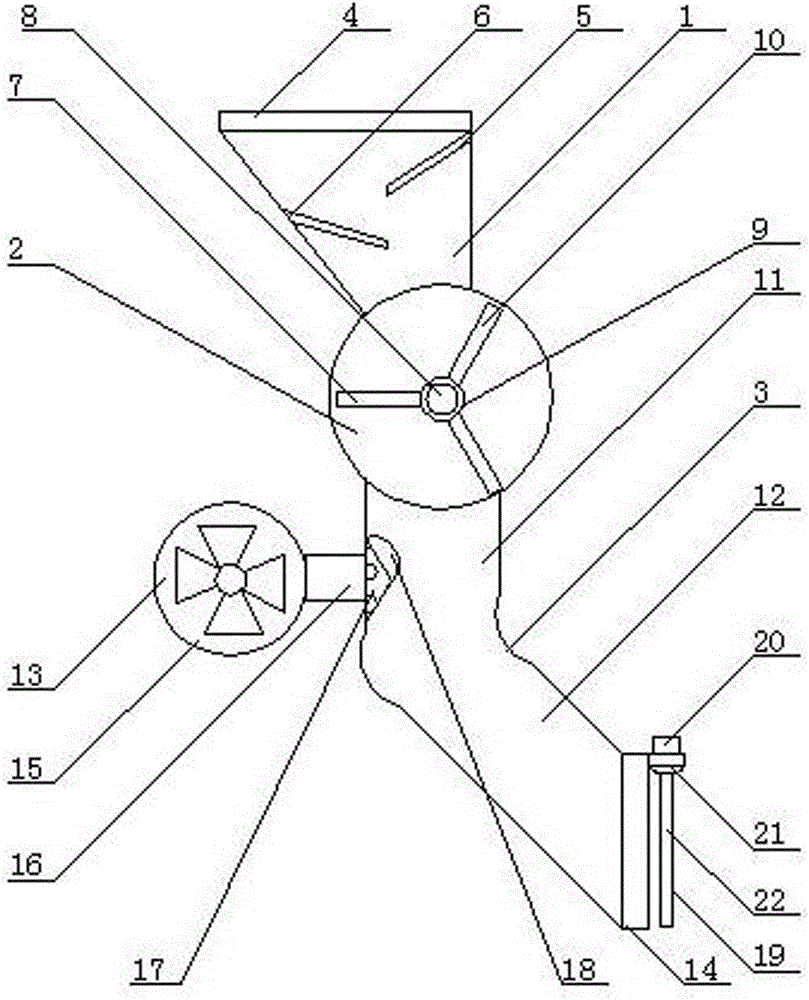

[0016] As shown in the figure, a fuel feeding mechanism that can adjust the feeding speed includes a feeding mechanism body, a feeding funnel 1 is installed at the top of the feeding mechanism, and a circular feeding chamber 2 is installed at the bottom of the feeding funnel , the curved feed pipe 3 is installed at the bottom end of the circular feed chamber 2 .

[0017] The sealing door 4 is installed at the top of the feeding funnel 1, the left side of the feeding funnel 1 is set as an inclined type, the upper right end of the feeding funnel 1 is equipped with a first inclined plate 5, and the middle end of the feeding funnel 1 is equipped with a second inner left side. Inclined board6.

[0018] The inside of the circular feed chamber 2 is equipped with a feed runner 7, the middle end of the feed runner 7 is equipped with a drive roller 8, the drive roller 8 is connected to a drive motor, and the outside of the drive roller 8 is equipped with a drum 9. 9 three buffer baffle...

Embodiment 2

[0023] Further, the left side of the first inclined plate 5 and the second inclined plate 6 are movable plates.

Embodiment 3

[0025] Further, the left side of the first inclined plate 5 and the right side of the second inclined plate 6 are on the same vertical horizontal line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com