Selective-radiation infrared stealth structure

A selective, infrared technology, applied in the field of infrared stealth, can solve problems such as low emission, and achieve the effect of meeting stealth requirements and efficient heat dissipation windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

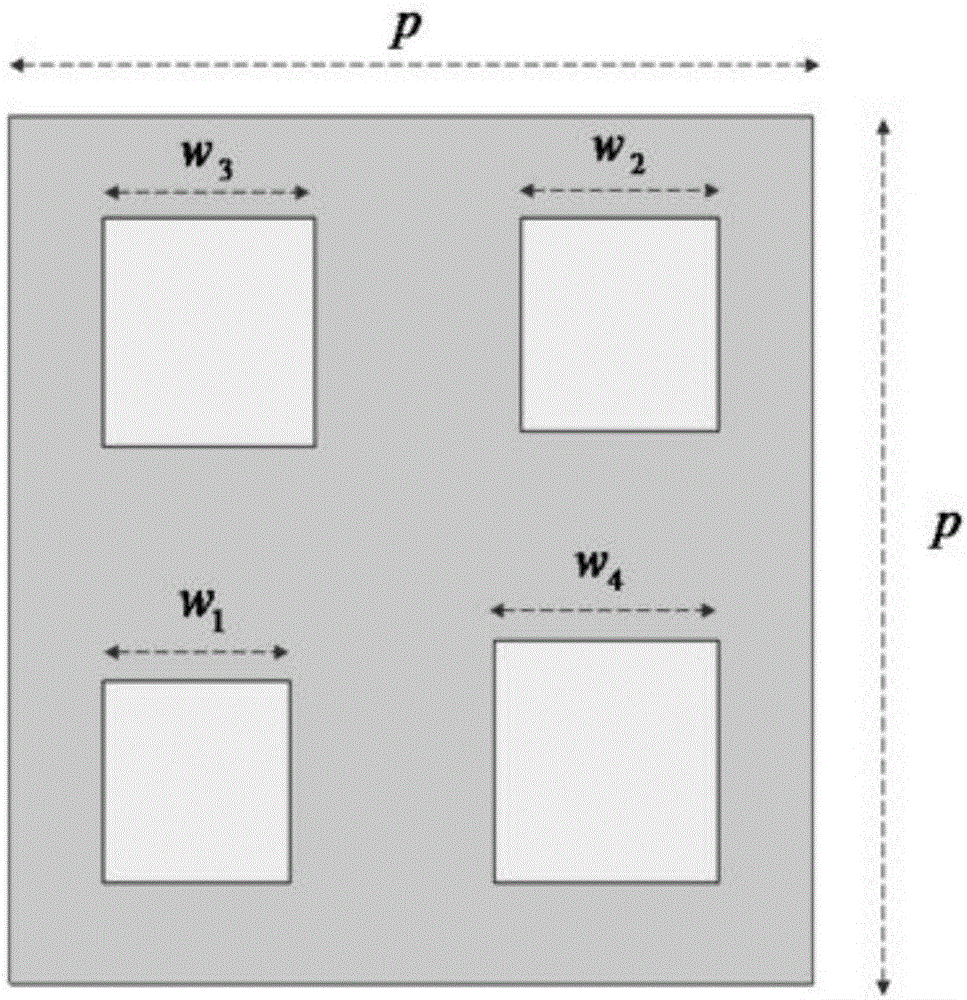

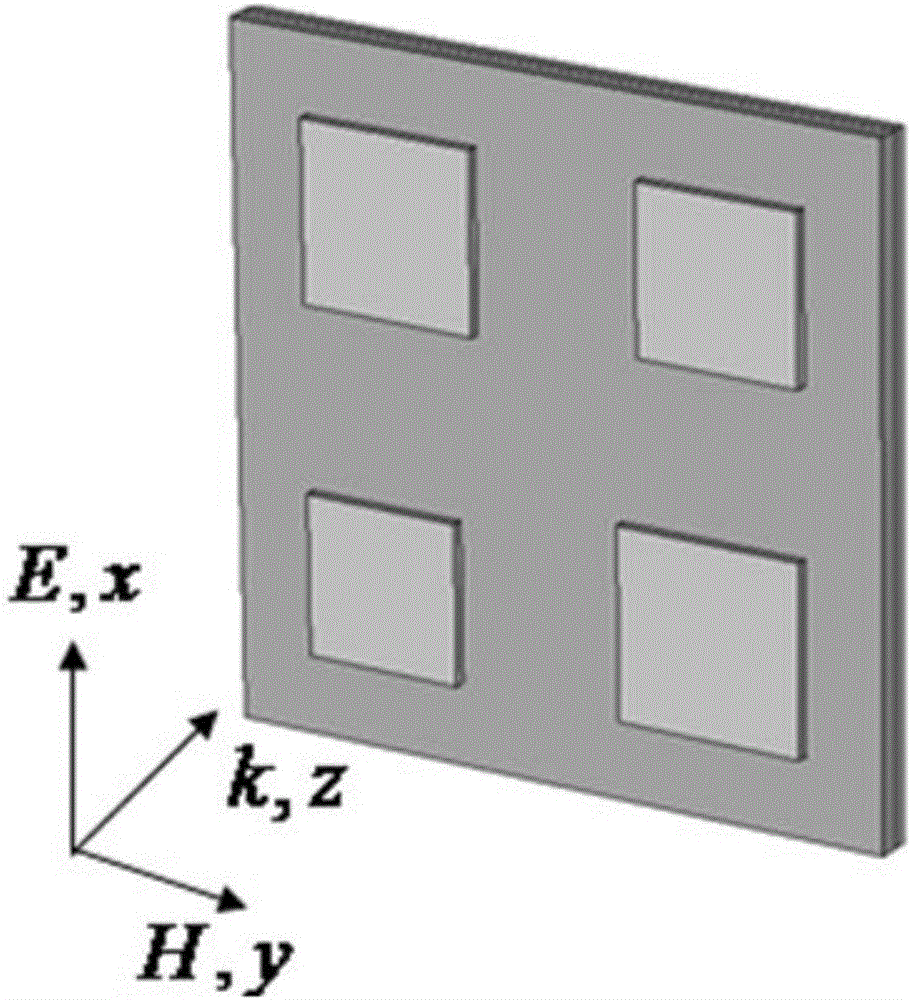

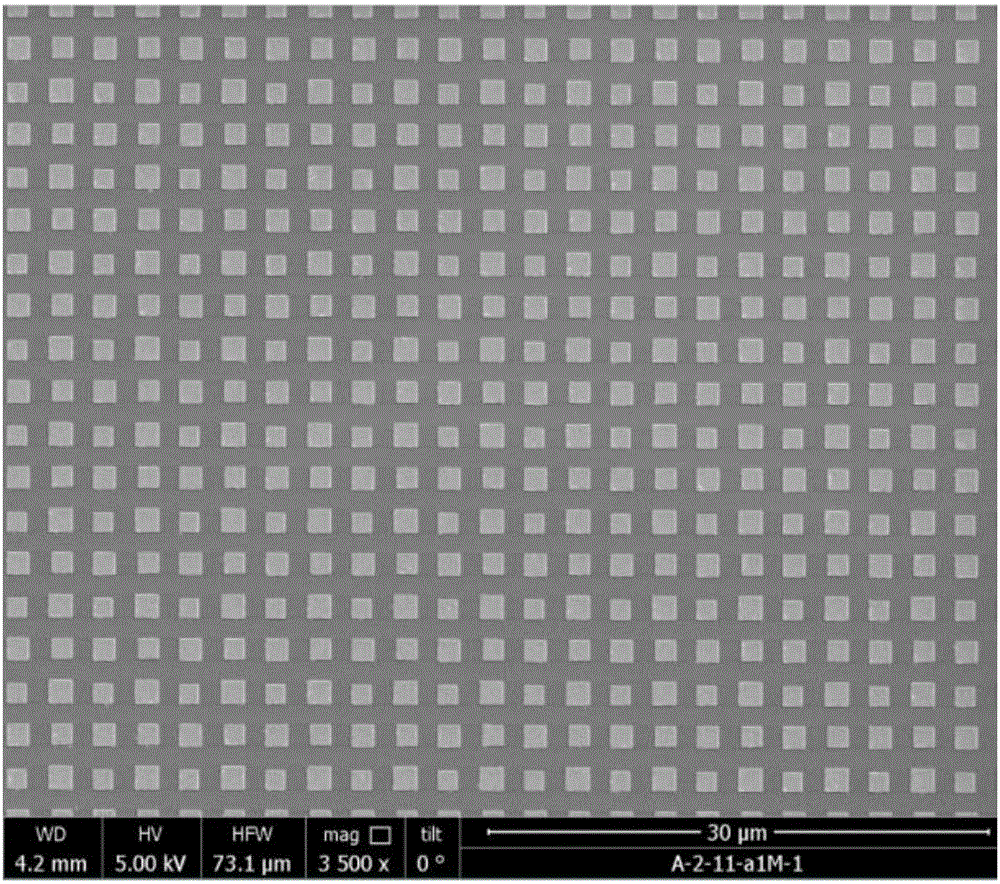

[0028] combine Figure 1-Figure 3 As shown, Embodiment 1 of the present invention provides a selective radiation infrared stealth structure, including a plurality of infrared selective heat emitting units arranged in a matrix according to a period p.

[0029] Each infrared selective heat emission unit includes a substrate layer, a metal back plate, a dielectric layer and a metal sheet layer arranged in sequence from bottom to top, and the metal sheet layer includes a first metal sheet, a second metal sheet, a third metal sheet and a first metal sheet Four metal sheets, the first metal sheet, the second metal sheet, the third metal sheet and the fourth metal sheet are arranged on the dielectric layer in a 2*2 array, and the first metal sheet, the second metal sheet, and the third metal sheet and the side lengths of the fourth metal sheet are all different.

[0030] Wherein, the substrate layer is made of Si sheet, the thickness of the substrate layer is 0.5mm, the metal backpl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com