Method for measuring micro deformation of structures under thermal vacuum high-and-low-temperature environments

A measurement method, high and low temperature technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as measurement data distortion, achieve the effect of improving measurement accuracy, avoiding measurement errors, and solving the problems of shape and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

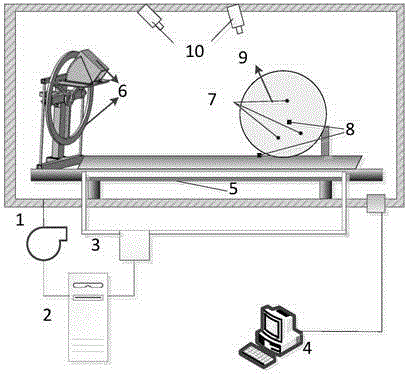

[0023] The test system of the method for measuring structural micro-deformation in a thermal vacuum high and low temperature environment of the present invention is mainly composed of three parts: a measurement subsystem, a temperature control subsystem and a structural support subsystem. The measurement subsystem consists of a camera protection unit 6, a speckle camera 10 and its protection devices. The camera protection unit 6 mainly uses high and low temperature motors to drive the monocular camera to acquire the spatial points of the target during spatial movement, calculate the spatial point coordinates, and perform feature fitting to obtain the deformation before and after it. The speckle camera and its protection device 10 mainly use a high-precision CCD camera to capture the point cloud of the digital speckle sprayed on the structure to be tested, and obtain the deformation before and after the sub-region autocorrelation. The temperature control sub-system mainly uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com