Tripper movement positioning control device and tripper movement positioning control method

A control device and mobile positioning technology, applied in the direction of measuring device, program control, computer control, etc., can solve problems such as inability to locate correctly, damage detection sensors, and affect the dust removal effect of the silo, so as to achieve an optimized and clean environment, save electric energy and Raw materials, the effect of improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be pointed out that the following detailed description is exemplary and intended to provide further explanation to the present application. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs.

[0033] As introduced in the background technology, in the prior art, the proximity switch is easily damaged, the detection accuracy is not high, the correct interlock opening and closing of the dust removal valve cannot be realized, and the detection mechanism is easily damaged when installed on the track or the unloading car. To solve the above technical problems, the present application proposes a device and method for controlling the movement and positioning of an unloading vehicle.

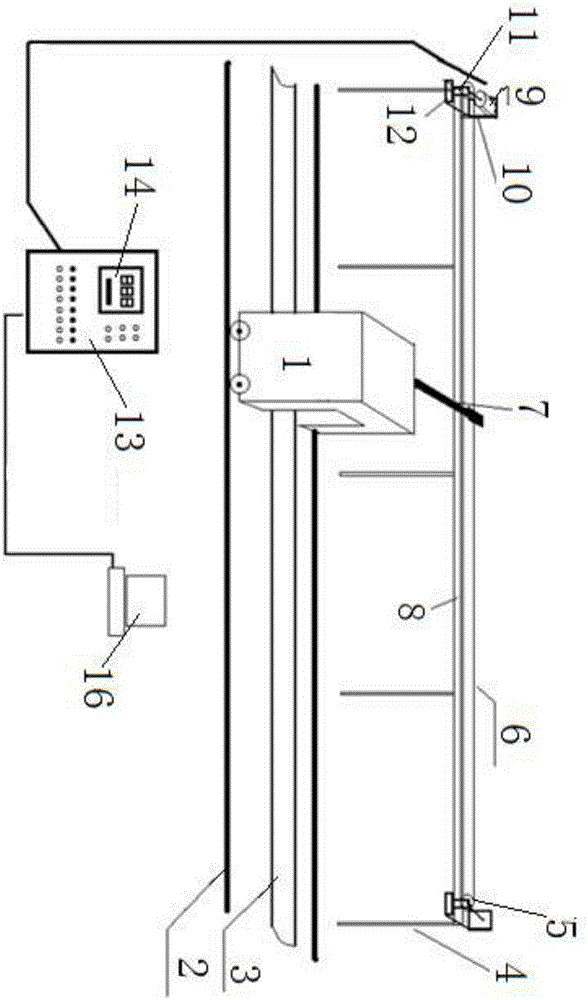

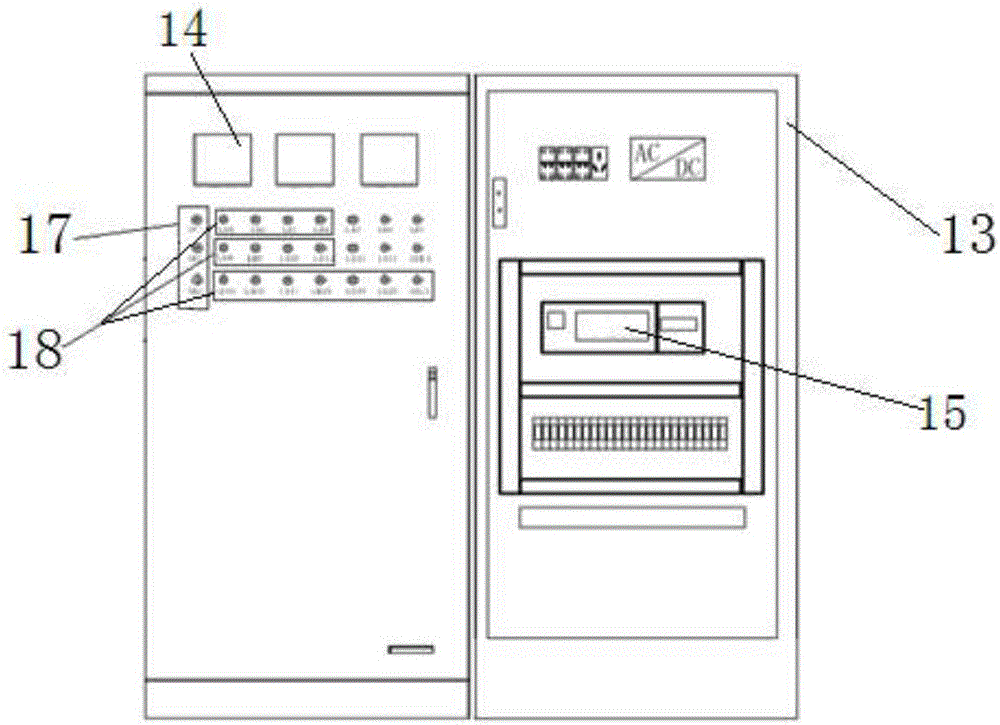

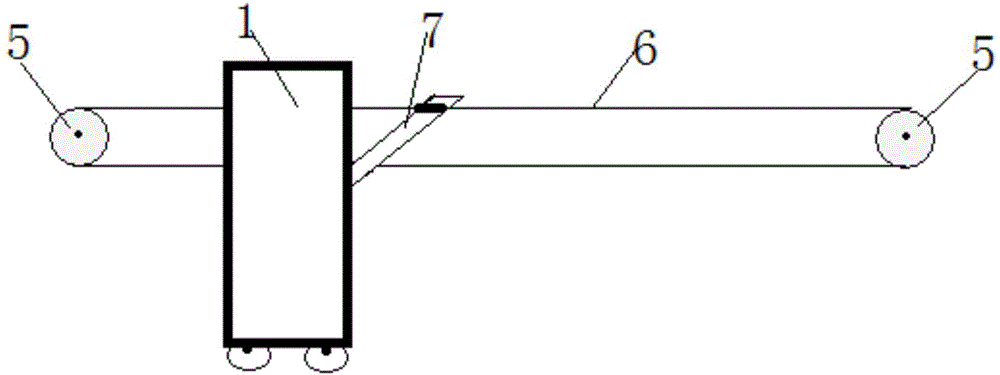

[0034] In a typical embodiment of the present invention, such as Figure 1-4 As shown, a control device for moving and positioning an unloading vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com