Inner-outer tube type gas flowmeter and flow detecting method

A technology of gas flowmeter and outer tube, which is applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detection by measuring pressure difference, etc., and can solve problems such as narrow range ratio, fluid disturbance, pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, an inner and outer tube gas flow meter.

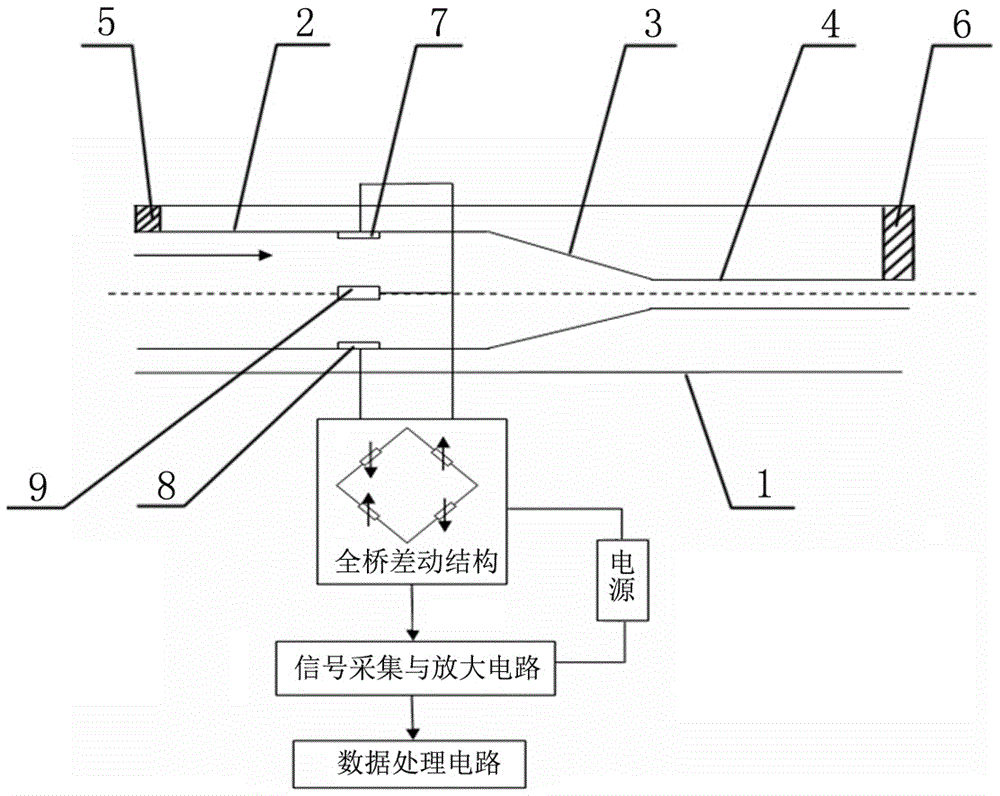

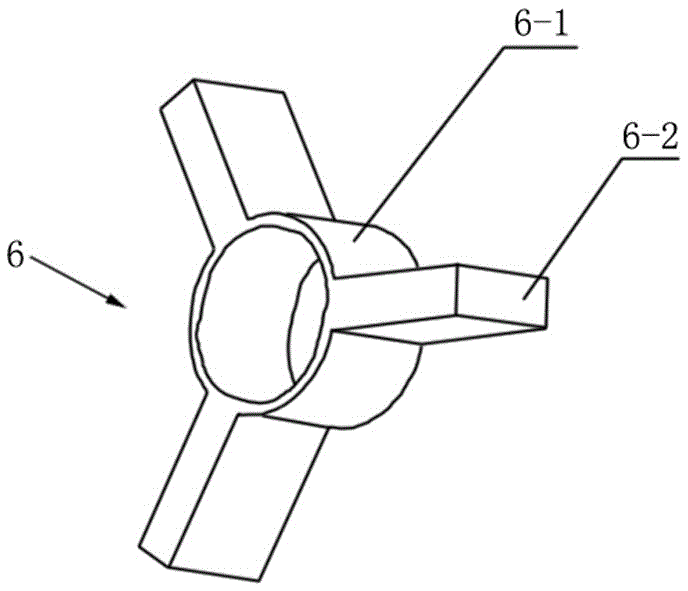

[0061] Such as figure 1 As shown, the inner and outer tube gas flowmeter provided by the present invention includes an outer tube 1, an inner tube, a bracket, a full-bridge differential structure composed of four strain gauges, a power supply, a signal acquisition and amplification circuit, and a data processing circuit.

[0062] The outer tube 1 is a cylindrical straight tube structure placed horizontally; the inner diameter of the outer tube 1 is represented by D, and the length is represented by L. The inner tube is a throttling part, and the inner tube is arranged in the outer tube 1, and the inner tube is located on the axis of the outer tube 1, that is, the axis of the outer tube 1 coincides with the axis of the inner tube. The length of the inner tube is the same as the length L of the outer tube 1 , and the two ends of the inner tube are respectively aligned with the two ends of the outer tube 1 . The inn...

Embodiment 2

[0082] Embodiment 2, an inner and outer tube type gas flow detection method.

[0083] Such as Figure 1 ~ Figure 2 As shown, the inner and outer tube type gas flow detection method provided by the present invention comprises the following steps:

[0084] a. Set the inner tube on the axis line inside the outer tube 1 .

[0085] The outer tube 1 is a circular straight tube structure placed horizontally. An inner tube is arranged on the axis of the outer tube 1; the inner tube includes a large-diameter tube 2, a shrink tube 3 and a small-diameter tube 4 connected in sequence; the shrink tube 3 has a frusto-conical structure; the large-diameter tube 2 and the small-diameter tube 4 The ends of the tubes are respectively aligned with the two ends of the outer tube 1, that is, the inner tube and the outer tube 1 have the same length. The distance between the outer wall of the large diameter tube 2 and the inner wall of the outer tube 1 is greater than 1 mm. On the same cross-sect...

Embodiment 3

[0106] Example 3, throttling ratio β and contraction angle preferred embodiment of .

[0107] According to the empirical theory and the consideration of the total pipe size, the shrinkage angle of the shrinkage tube Set it as 15°, and then calculate the inner diameter of the large-diameter pipe and the inner diameter of the small-diameter pipe under different throttling ratios, and then carry out the simulation according to the determined structural size at the inlet velocity of 10.27m / s, and obtain the flow rate according to the simulation results Calculate the pressure values at multiple places, specifically: ① Obtain the differential pressure between the inner and outer pipes, ② Obtain the pressure difference between the 10D (D is the inner diameter of the outer pipe) before the inflow end of the outer pipe (or inner pipe) and the 5D behind the outflow end. Pressure difference, this is the pressure loss. The pressure loss ratio is obtained by dividing the pressure los...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com